Clamping tool provided with air cylinder and restoring torsion springs

A technology for restoring torsion springs and cylinders, applied to components with teeth, manufacturing tools, metal processing equipment, etc., can solve the problems of time-consuming and laborious, waste of resources, and reduce production efficiency, and achieve a wide range of applications, easy implementation, and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

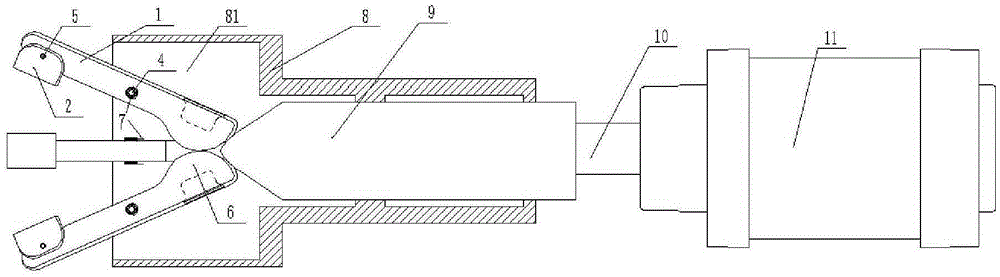

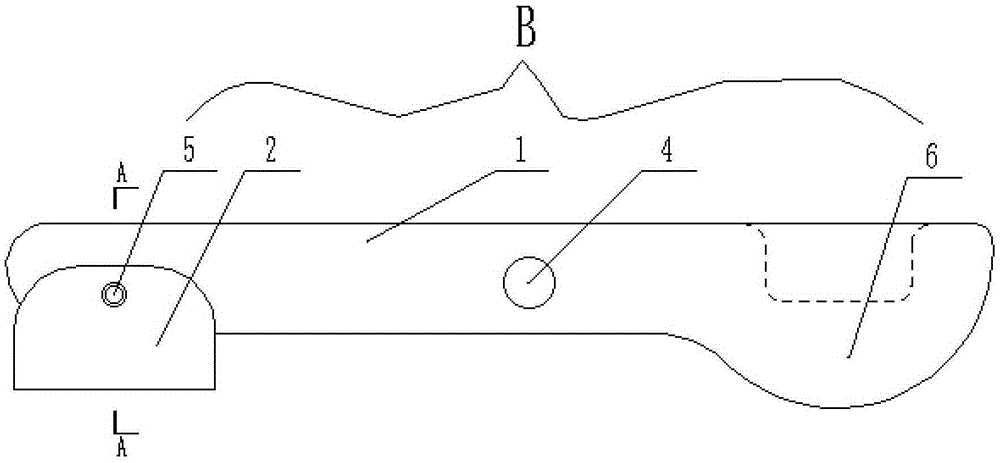

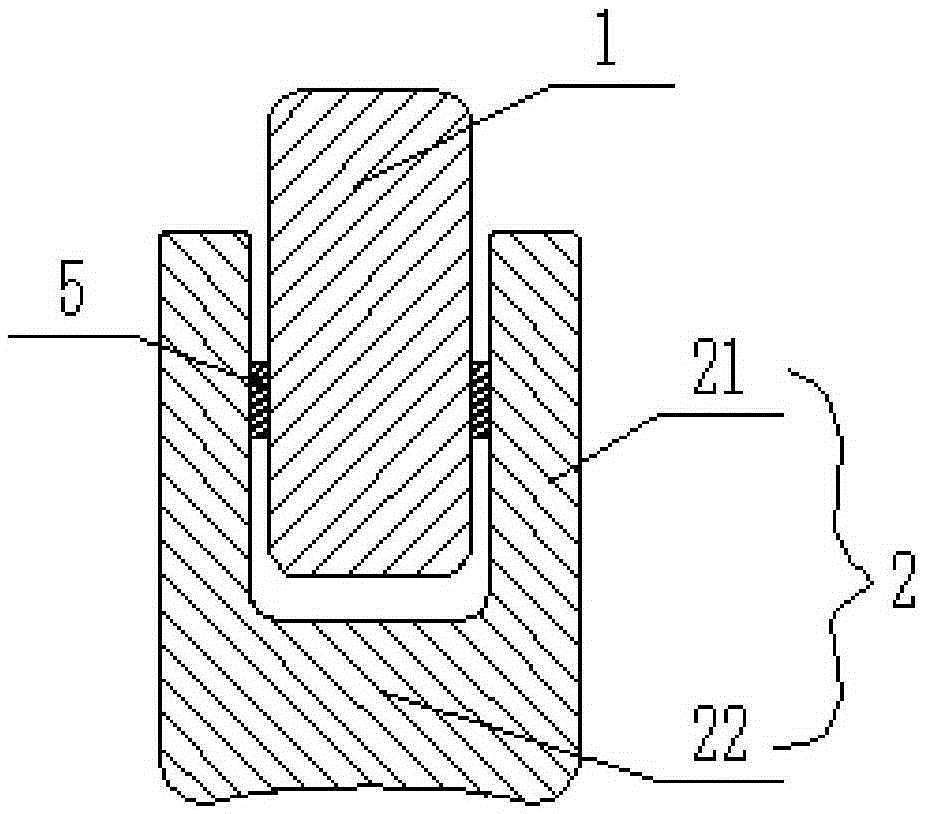

[0018] Such as figure 1 As shown, a clamping tool with a cylinder and a return torsion spring includes a mounting base 8, and the mounting base 8 is provided with a mounting cavity 81, and three clamping arms B are arranged in the mounting cavity 81. The holding arms B are evenly distributed in the circumferential direction, and the heads of the holding arms B protrude forward from the installation cavity 81 respectively. The middle parts of the holding arms B are respectively hinged with the mounting base 8, that is, the holding arms B The middle part is hinged in the installation cavity 81 through the lever installation shaft 4, and the same clamping arm push rod 9 is perforated in the mounting seat 8 behind the clamping arm B, and the front end of the clamping arm push rod 9 Align the tail of the clamping arm B. When the clamping arm push rod 9 adva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com