A vertical disassembly and assembly equipment for hydraulic support columns

A hydraulic support column and vertical technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of unsafe manual support of the live column, and achieve a system that is conducive to popularization, improves system reliability, and has a high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

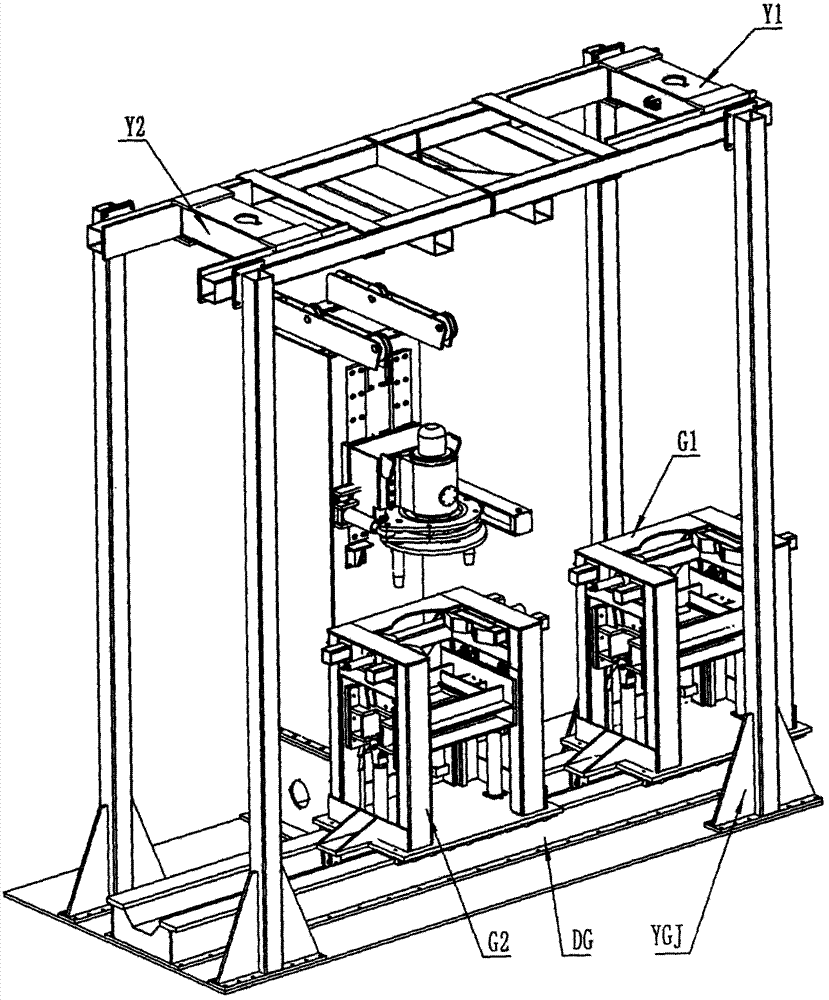

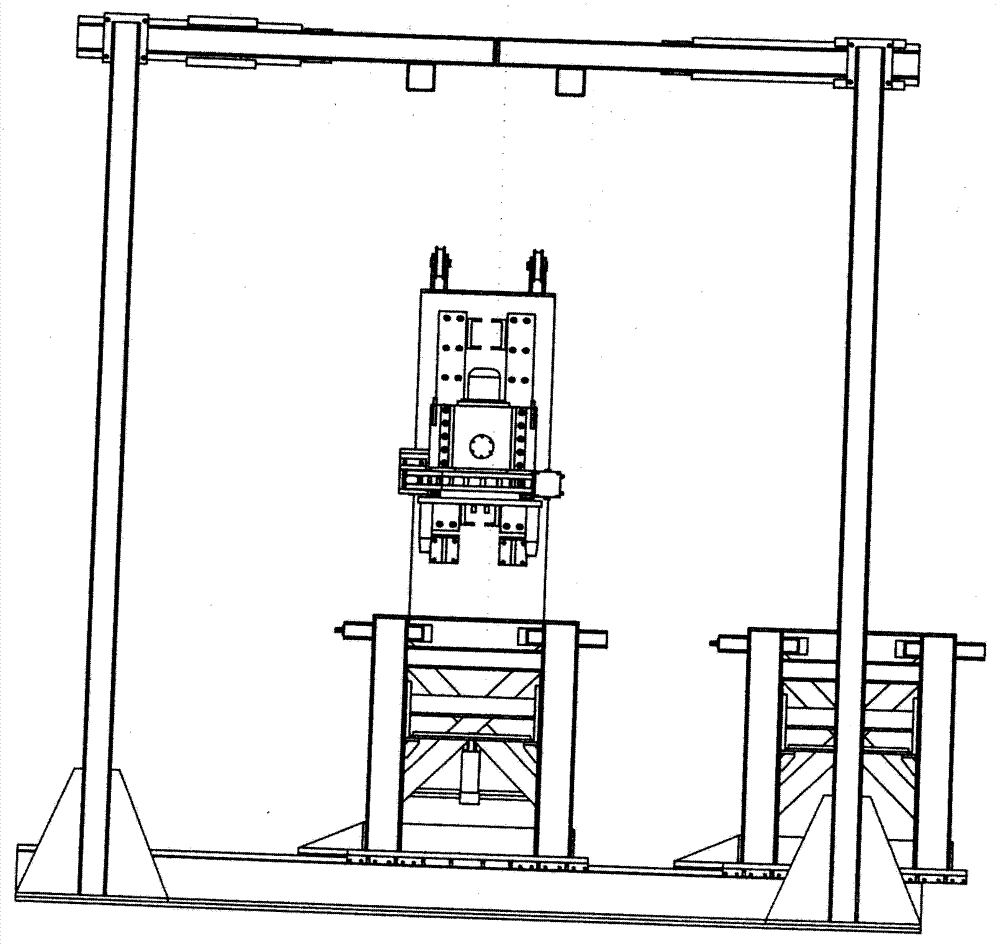

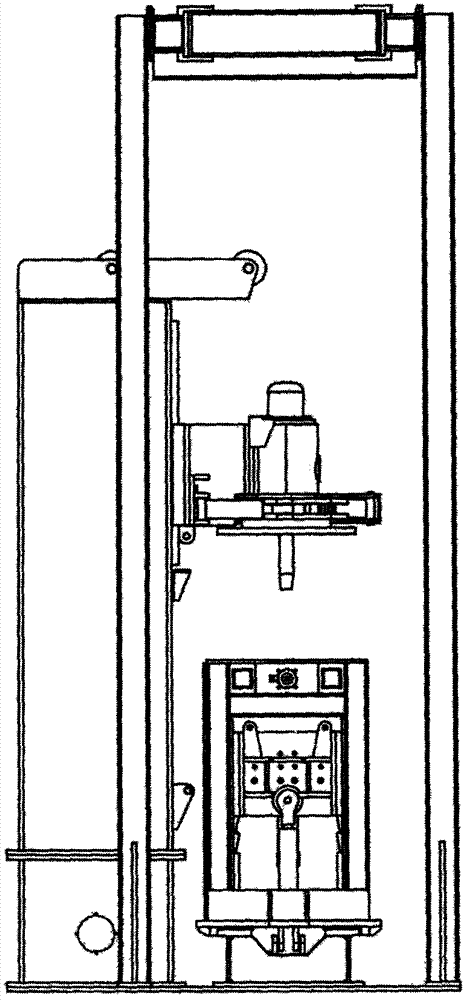

[0057] This hydraulic support column vertical disassembly equipment includes double-vehicle double-station operation procedures, a synchronous lifting frame structure, a plug-in pin positioning device, a synchronous cylinder support mechanism, a mechanical support column device, and an intelligent electrical control system. Embodiment is as follows: (1), two-car double-station work procedure. See figure 1 , 2 , 3. The L-shaped frame base of the original equipment is separated from the vertical beam, and the vertical beam is welded on the steel plate base vertically to form a new cylinder frame YGJ. The front bottom plate of the vertical beam fixes a horizontally recumbent feeding car sliding track DG, and the length of the track DG is greater than the width of the three feeding cars. The right station feeds the trolley G1 and the left station feeds the trolley G2, and they are arranged on the DG table top of the feed car slide track at a certain distance. The left and righ...

Embodiment approach

[0064] (4), newly added mechanical supporting column device, the present invention discloses the following four implementations: guide rod clamping supporting column device, swing arm rotating rod supporting column device, horizontal pushing hydraulic cylinder centralizing device, living column centralizing four-bar linkage mechanism . Guide rod clamping support column device such as Figure 8 , 9 , Shown in 10, this mechanical supporting column device is integrally fixed on the improved double-station operation press cylinder frame YGJ. Lifting motor 50 is fixed on motor holder 52 by connecting sleeve 51, and motor holder 52 is then fixed on the cylinder frame YGJ, and bearing 53 is sleeved on the transmission screw 54, and bearing outer ring is fixed in motor holder 52. Nut 61 is fixedly connected on the guide sleeve 60, and the supporting column device connecting rod 63 is hinged on the guide sleeve 60 slide seat by the pin shaft 62, and supports the column hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com