Automatic skating roller assembling method and device

An automatic assembly and ice wheel technology, applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of poor assembly quality and low efficiency of roller skating assembly, and achieve good assembly quality consistency, smooth and compliant operation, and automation level high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below in conjunction with specific embodiments.

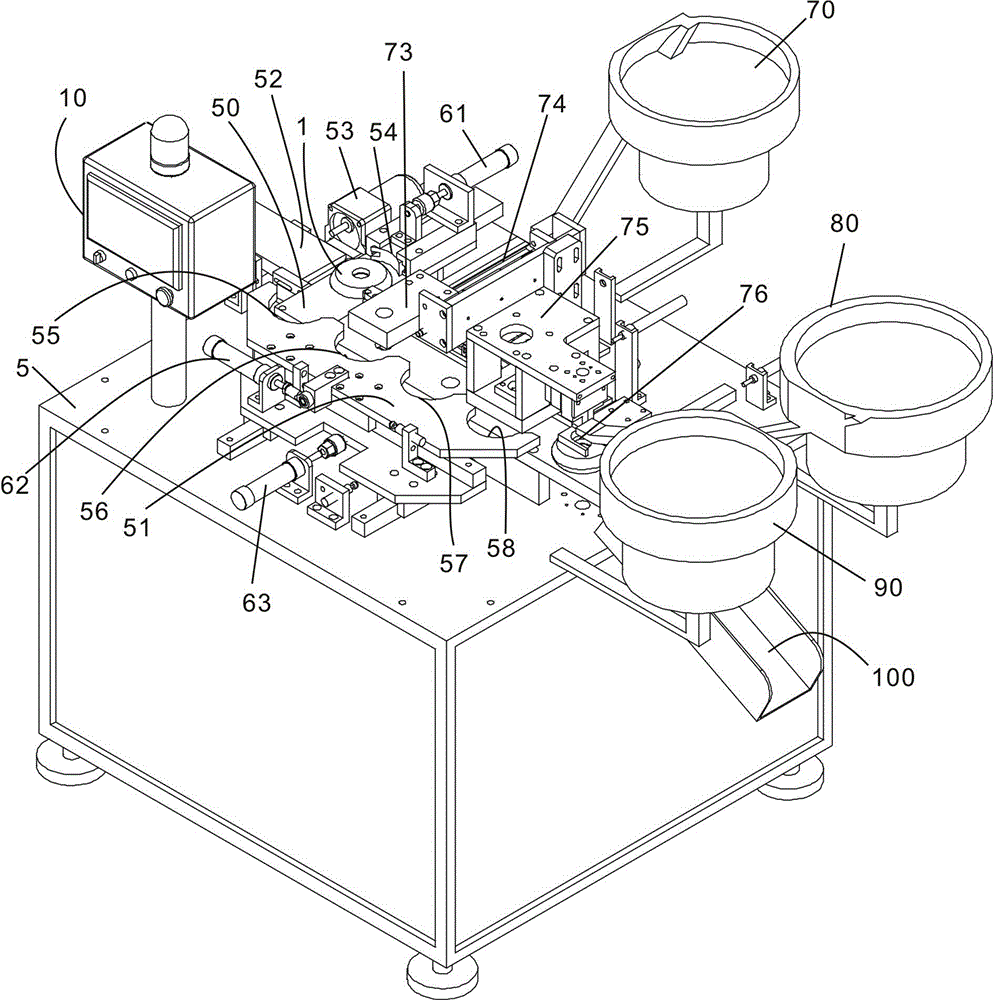

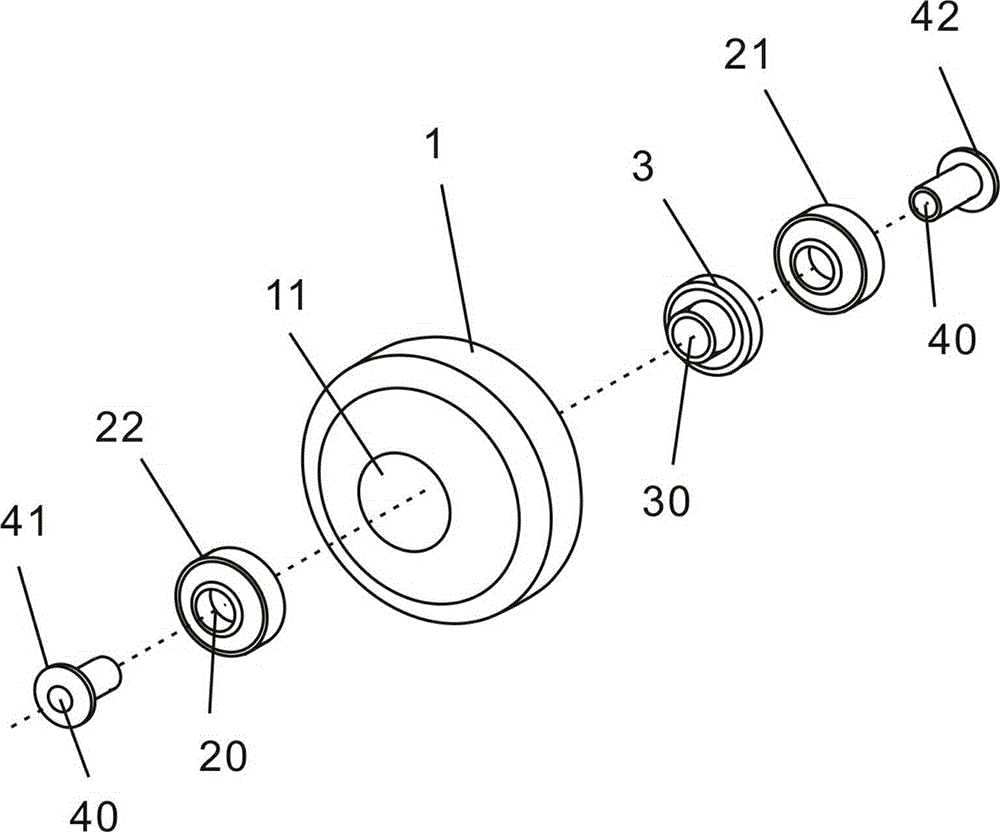

[0039] Such as Figure 1 ~ Figure 3 Shown, implement a kind of method for automatic assembly of roller skate wheel, comprise the steps:

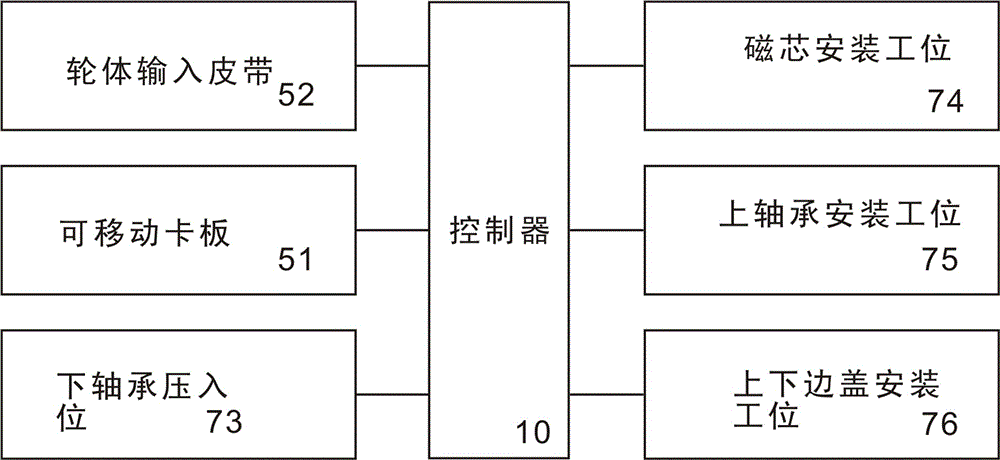

[0040] S1. First, set a base plate 50 on the frame platform 5, and then set a movable clamping plate 51 based on the base plate 50. The movable clamping plate 51 has a first clamping slot 55, a second clamping slot 56, and a third clamping slot. Slot 57, the fourth card slot 58;

[0041] S2, then when the movable clamping plate 51 is at the starting position; the push head 54 of the roller body 1 is set on the opposite side of the first draw-in groove 55, and the push head 54 is responsible for sending the roller wheel sent by the wheel body input belt 52 The wheel body 1 is pushed into the first slot 55;

[0042] S3. Next, the movable clamping plate 51 moves forward for a distance of one clamping position, and the roller body 1 in the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com