A shock absorber bearing pressure intercommunication conversion system that realizes the change of the top and bottom of the wheel with the terrain

A conversion system and shock absorber technology, which is applied in interconnection systems, vehicle components, elastic suspensions, etc., can solve the problem of inability to realize the overall lifting of the car on one side, the long time for the car body to recover smoothly, and the heavy pressure on the wheels. Unevenness and other problems, to achieve the effect of increasing safety and stability, uniform wheel bearing pressure, and uniform wheel bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

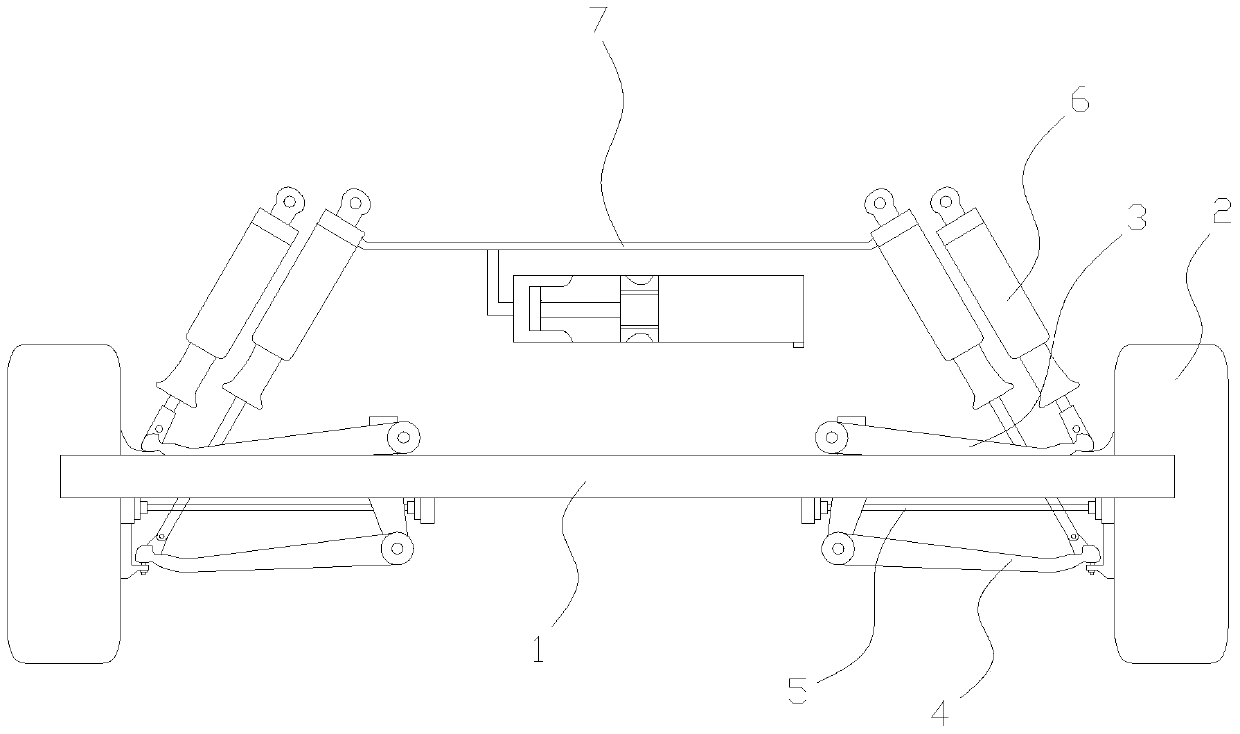

[0027] Such as figure 1 with 2 As shown, the load-bearing pressure intercommunication conversion system of the shock absorber that realizes the change of the wheel up and down with the terrain includes a vehicle frame 1, a wheel set, an upper control arm 3, a lower control arm 4, a transmission shaft 5, and a shock absorber 6. The wheel set includes Four wheel sets on the same end and side of the frame 1, each wheel set includes a wheel 2, each wheel 2 is connected to the frame 1 through the upper control arm 3 and the lower control arm 4, and the transmission shaft 5 is connected to the Between the wheel 2 and the vehicle frame 1, the shock absorber 6 is an air shock absorber, and the shock absorber 6 is arranged on the upper side of the upper control arm 3 and the lower control arm 4 respectively. Two of the shock absorbers 6 above the wheels 2 on the same end side of the vehicle frame 1 communicate through the first fluid pipe 7, and the remaining two shock absorbers 6 abo...

Embodiment 2

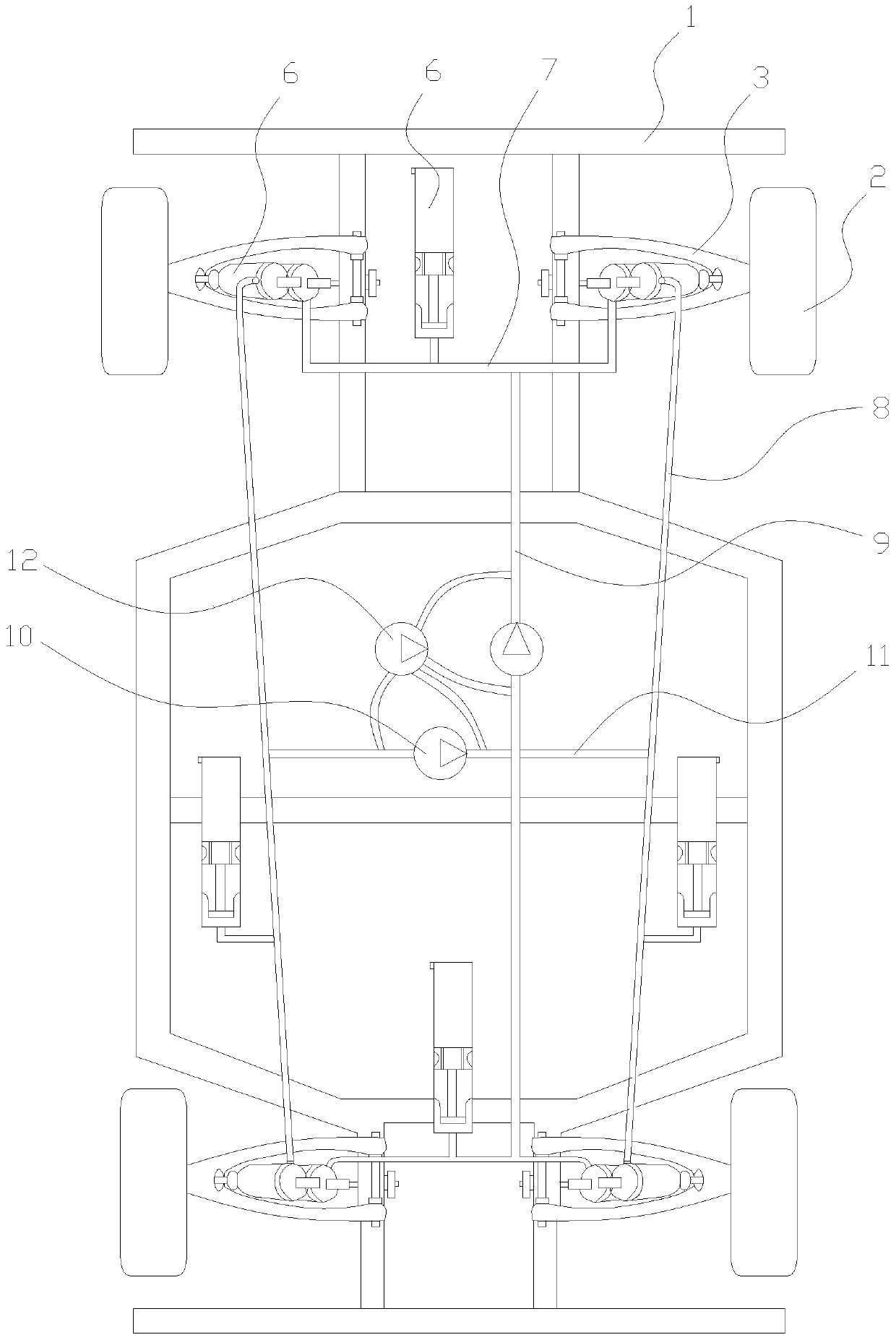

[0031] Such as figure 1 with 3 As shown, the load-bearing pressure intercommunication conversion system of the shock absorber that realizes the change of the wheel up and down with the terrain includes a vehicle frame 1, a wheel set, an upper control arm 3, a lower control arm 4, a transmission shaft 5, and a shock absorber 6. The wheel set includes Four wheel sets on the same end and side of the frame 1, each wheel set includes 1 to 2 wheels 2, specifically, the front wheel set is provided with 1 wheel 2 and the rear wheel set is provided with 2 wheels 2 , each wheel 2 is respectively connected to the vehicle frame 1 through the upper control arm 3 and the lower control arm 4, the transmission shaft 5 is connected between the wheel 2 and the vehicle frame 1, the shock absorber 6 is a hydraulic shock absorber, and the shock absorber 6 They are arranged on the upper sides of the upper control arm 3 and the lower control arm 4 respectively.

[0032] Two or four of the shock ab...

Embodiment 3

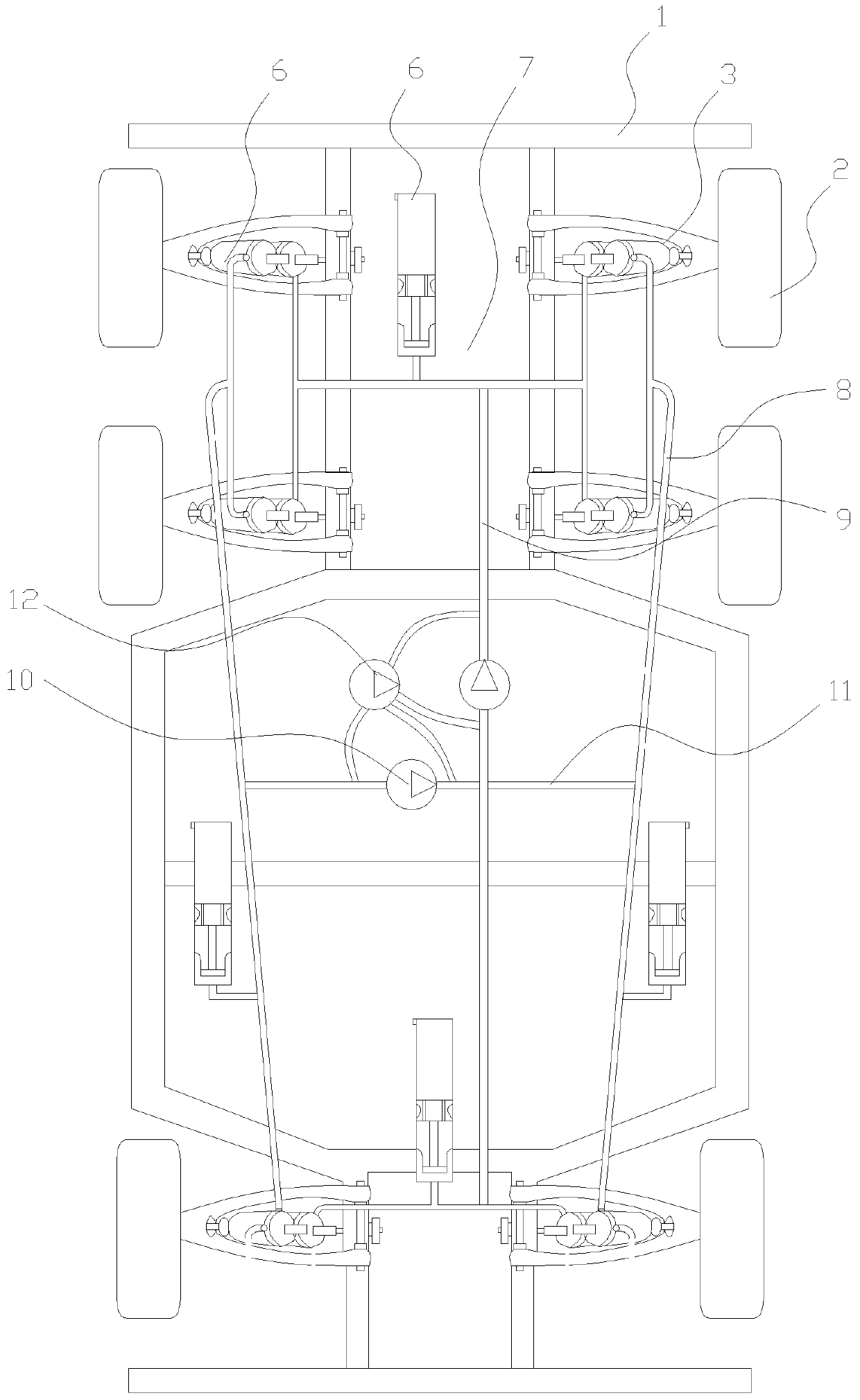

[0035] Such as figure 1 with 4As shown, the load-carrying pressure intercommunication conversion system of the shock absorber that realizes the up and down changes of the wheels with the terrain, each wheel set includes two wheels 2, specifically, the front wheel set is provided with two wheels 2 and the rear wheel set is provided with 2 wheels 2. Wherein four shock absorbers 6 above the wheels 2 on the same end side of the vehicle frame 1 communicate through the first fluid pipeline 7 (that is, the four shock absorbers 6 above the wheels 2 of the two front wheels at the front end pass through the first fluid pipeline 7 and the four shock absorbers 6 above the wheels 2 of the two rear wheels at the rear end communicate through the first fluid pipeline 7), and the remaining four shock absorbers above the wheels 2 on the same end side of the vehicle frame 1 The shock absorbers 4 communicate with the remaining shock absorbers 6 above the wheels 2 on the same side of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com