A Polyolefin Photovoltaic Film with High Peel Strength Retention

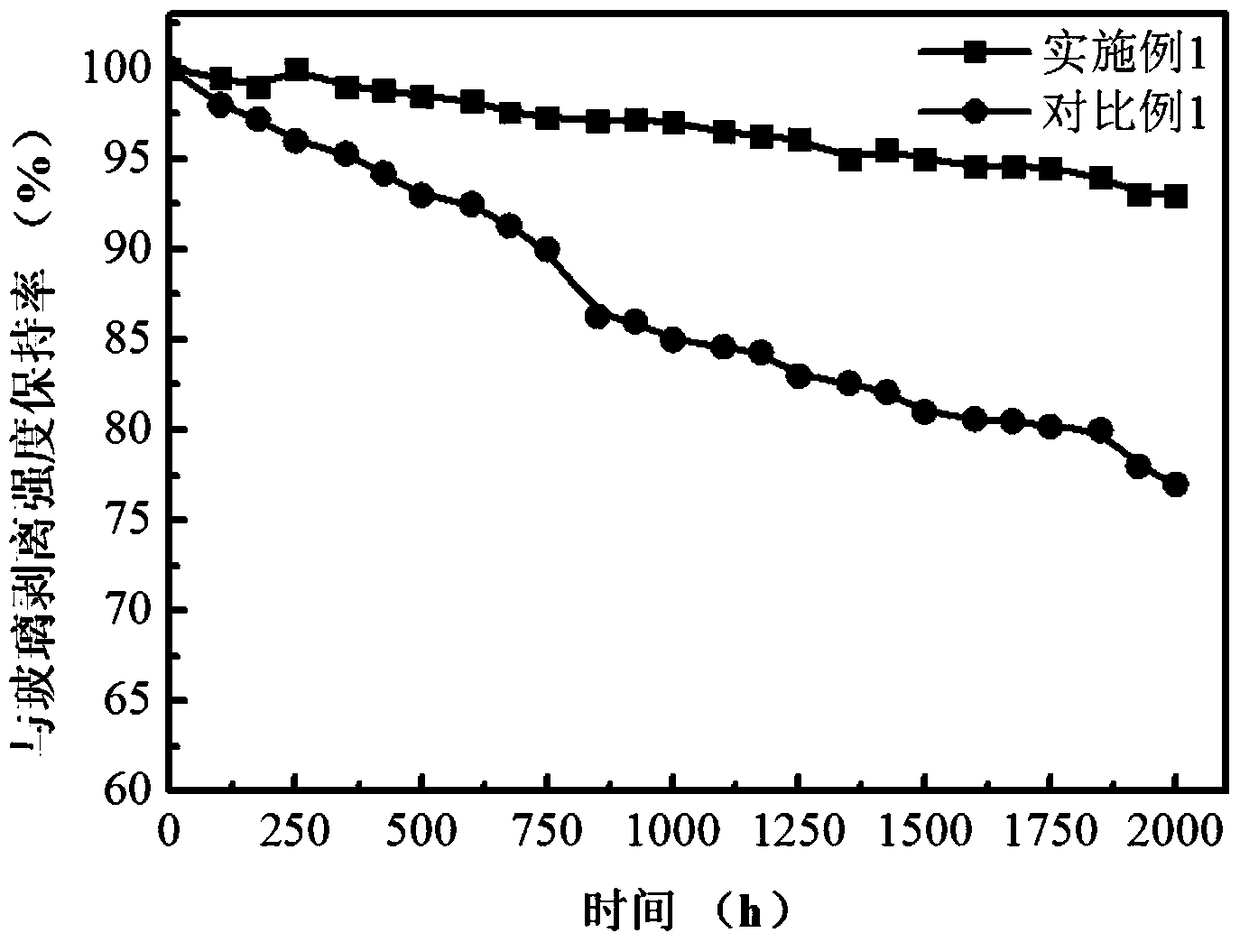

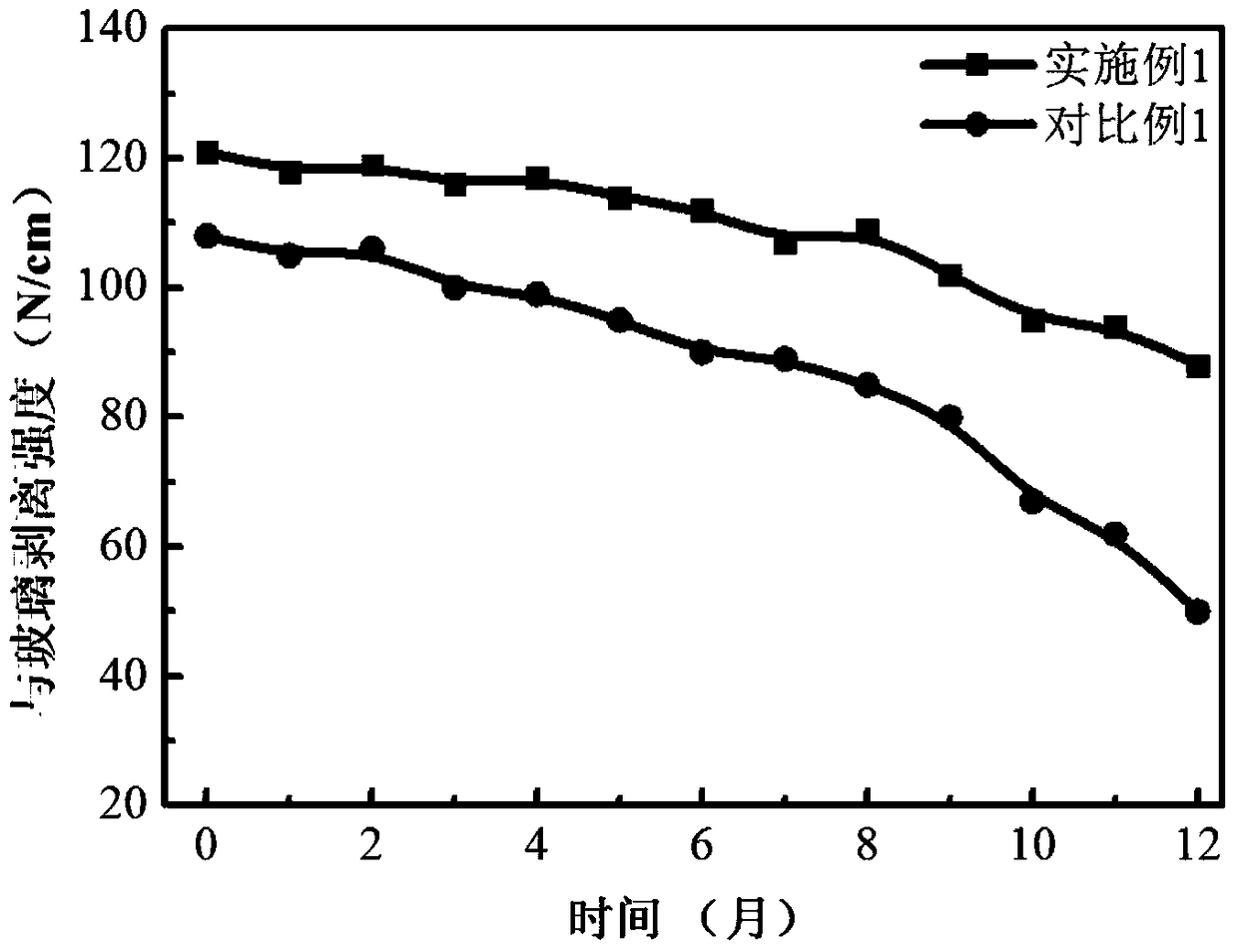

A strength retention, polyolefin technology, applied in the field of photovoltaic module packaging materials, can solve the problems of poor compatibility of non-polar substrates, easy failure of adhesive films, etc., to improve the poor compatibility and improve peel strength. retention rate, the effect of increasing application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

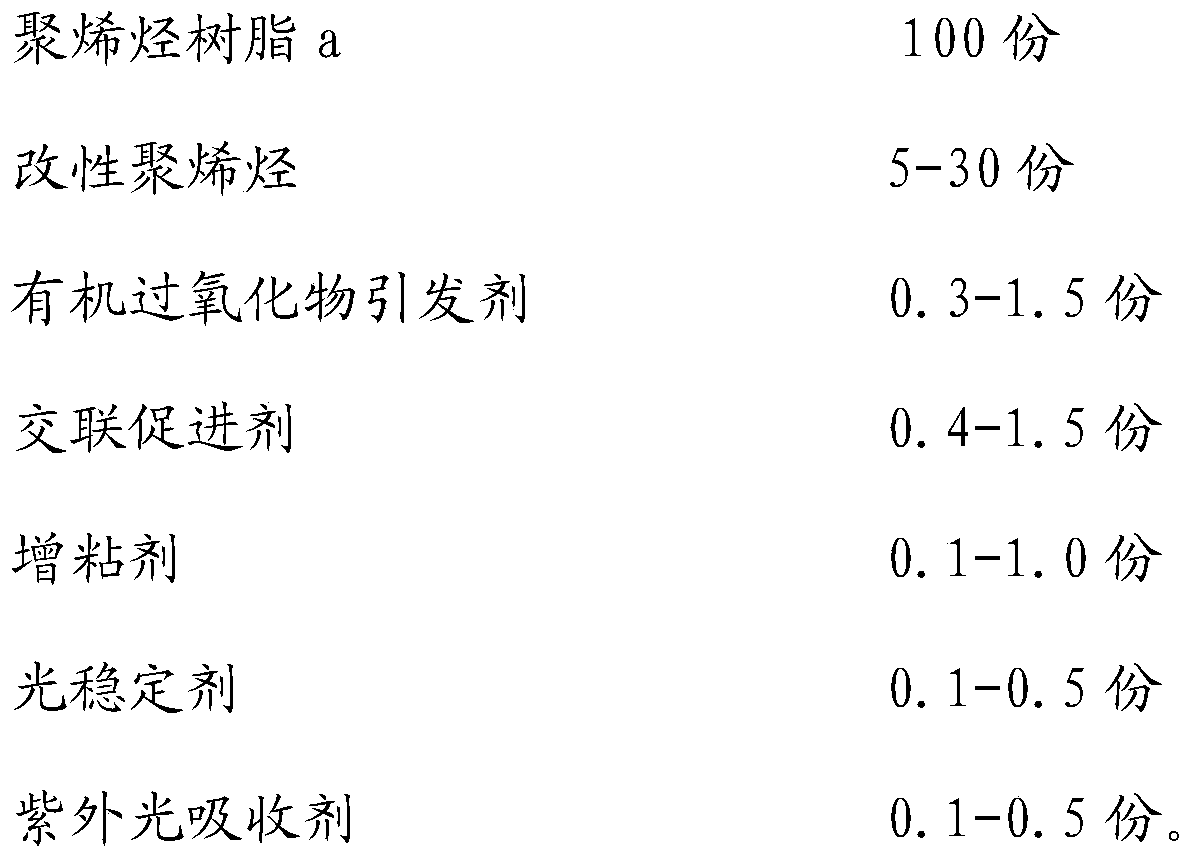

[0029] A polyolefin light film with high peel strength retention rate is composed of the following components in parts by weight: 100 parts of polyolefin (polyolefin resin a) with a melting index of 35g / 10min and a melting point of 60°C, 20 parts of polyolefin resin Branch γ-methacryloxypropyltrimethoxysilane masterbatch (modified polyolefin), 0.4 parts of 1,1-di-tert-butylperoxycyclohexane (organic peroxide initiator), 1.2 parts Triallyl cyanurate (crosslinking accelerator), 0.5 parts of vinyltrimethoxysilane (tackifier), 0.2 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate Ester (light stabilizer), 0.5 parts of 2-hydroxy-4-n-octyloxybenzophenone (ultraviolet light absorber), mix the above components evenly through the mixer, put them into the casting machine, press the setting With good process parameters, the polyolefin photovoltaic film is made through plasticizing extrusion, casting, traction and winding.

[0030] Wherein, the polyolefin grafted gamma-methacryloxypro...

Embodiment 2

[0032] A polyolefin optical film with a high peel strength retention rate is composed of the following components in parts by weight: 100 parts of polyolefin (polyolefin resin a) with a melting index of 3g / 10min and a melting point of 110°C, 10 parts of polyolefin Graft maleic anhydride masterbatch (modified polyolefin), 1.5 parts of tert-butyl peroxyisopropyl carbonate (organic peroxide initiator), 0.4 part of trimethylolpropane trimethacrylate (crosslinking accelerator agent), 1.0 part of γ-methacryloxypropyltrimethoxysilane (tackifier), 0.1 part of bis-2,2,6,6-tetramethylpiperidinol sebacate (light stabilized agent), 0.2 parts of 2-hydroxy-4-n-octyloxybenzophenone (ultraviolet light absorber). The above components are mixed evenly by the mixer, put into the casting machine, and according to the set process parameters, the polyolefin photovoltaic film is made through plasticizing extrusion, casting, traction and winding.

[0033]Wherein, polyolefin grafted maleic anhydride ...

Embodiment 3

[0035] A polyolefin light film with high peel strength retention rate is composed of the following components in parts by weight: 100 parts of polyolefin (polyolefin resin a) with a melting index of 20g / 10min and a melting point of 80°C, 30 parts of polyolefin Graft glycidyl methacrylate masterbatch (modified polyolefin), 0.3 parts of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane (organic peroxide initiator) , 1.5 parts of tetraallyloxyethane (crosslinking accelerator), 0.1 part of γ-aminopropyltriethoxysilane (tackifier), 0.5 parts of sebacic acid bis-2,2,6,6- Tetramethylpiperidinol ester (light stabilizer), 0.1 part of 2-hydroxy-4-n-octyloxybenzophenone (ultraviolet light absorber). The above components are mixed evenly by the mixer, put into the casting machine, and according to the set process parameters, the polyolefin photovoltaic film is made through plasticizing extrusion, casting, traction and winding.

[0036] Wherein, the polyolefin grafted glycidyl methacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com