Anti-seepage structure and anti-seepage treatment method for surface mine pit bottom

A technology for open-pit and mines, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of high cost of anti-seepage structure and poor anti-seepage effect, and achieve the effect of increasing cost, increasing drainage costs, and increasing water inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]For further describing the present invention, below in conjunction with accompanying drawing and example the present invention will be further described:

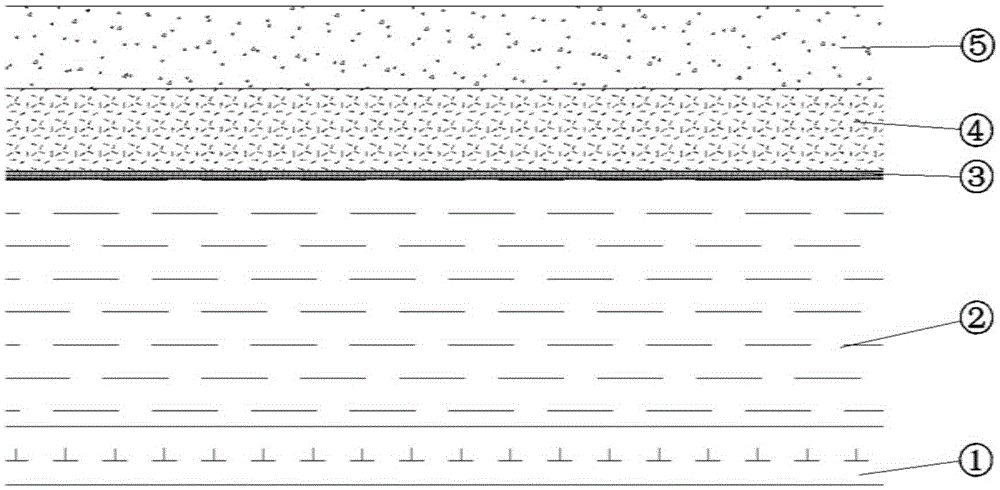

[0043] A kind of anti-seepage structure at the bottom of the open-pit mine of this example, the bottom of the open-pit 1 is a rock structure; at the bottom of the open-pit 1 upwards, such as figure 1 As shown in Fig. 1, the lower cushion layer 2, geomembrane 3, upper cushion layer 4 and protective layer 5 are laid in sequence; the lower cushion layer 2, geomembrane 3, upper cushion layer 4 and protective layer 5 are compacted clay, two cloth and one membrane Composite geomembrane, flattened tailings and glue-tailed sand; the thickness of compacted clay is 300mm, and both the flattened tailings and glue-tailed sand are 100mm; the gray-sand ratio of glue-tailed sand is 1:4; the two-cloth-one-film composite geomembrane The film thickness is not less than 0.5mm, and the cloth is geotextile;

[0044] The method for anti-s...

Embodiment 2

[0052] An anti-seepage structure at the bottom of an open-pit mine in this example, the basic structure is the same as in Example 1, and the improvements are: the glue tailing sand is replaced by a C10 concrete prefabricated slab; the flattened tailing sand is replaced by ordinary fine sand; cloth-membrane composite geomembrane It is a composite geomembrane with two cloths and one film, which improves the anti-seepage effect.

[0053] The anti-seepage structure at the bottom of a kind of open-pit mine pit and the method for anti-seepage treatment thereof of this example, the steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com