Anti-rock impact blocking structure of under-construction slope sliding system and construction method thereof

A slip-breaking system and rock technology are applied in the construction field of the rock-impact-resistant plugging structure of the slip-breaking system and its construction field, which can solve problems such as delaying the construction period, and achieve the effects of improving safety and reliability and reducing impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

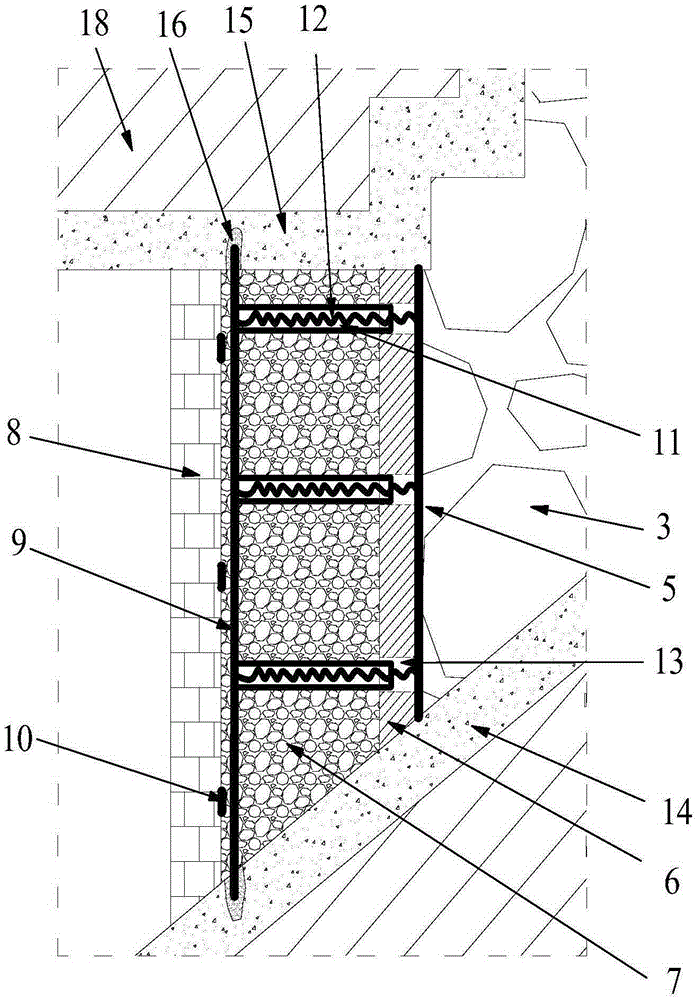

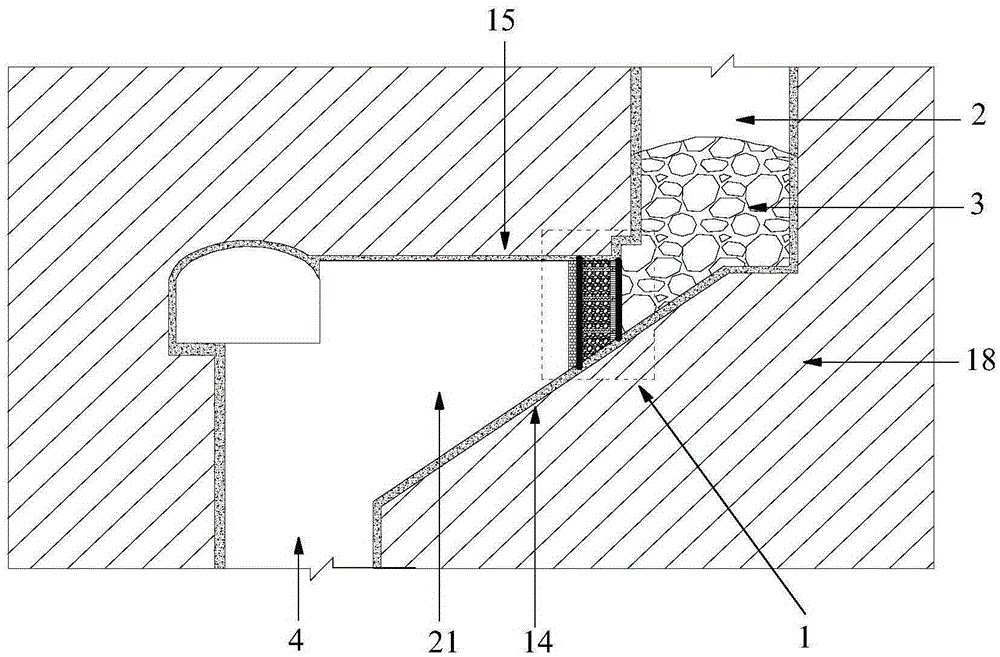

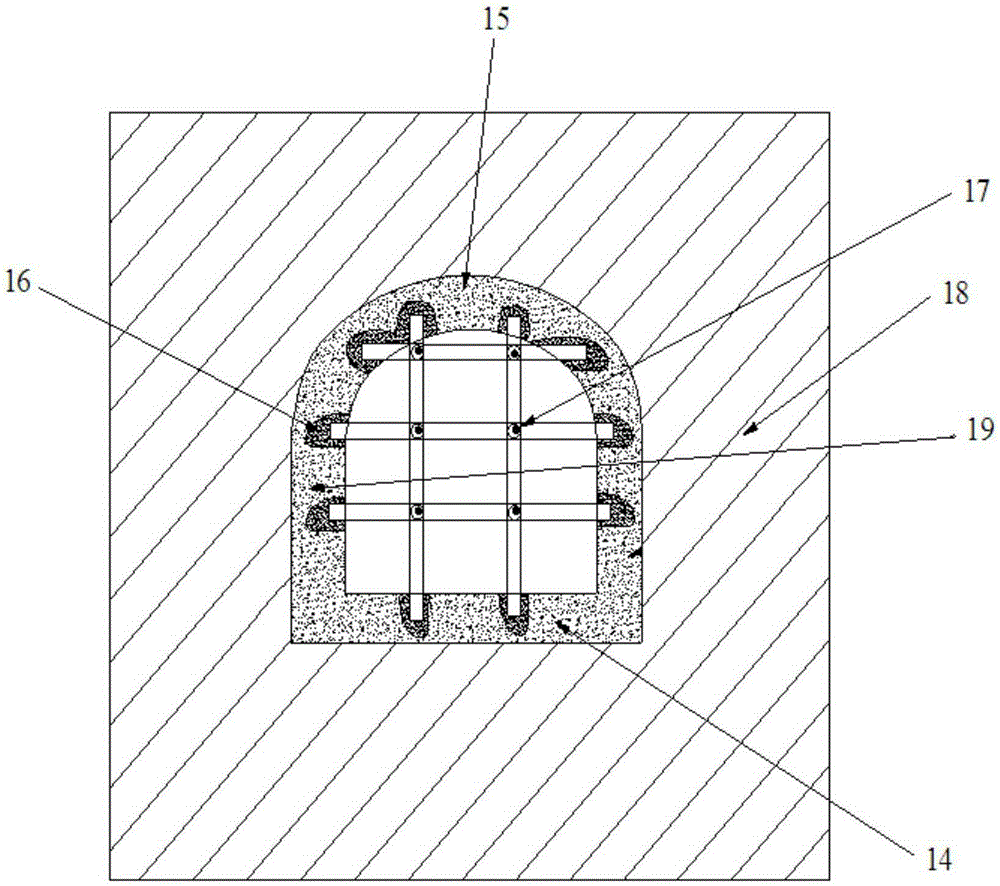

[0029] Such as figure 1 , figure 2 As shown, the sealing structure 1 of the present invention includes an I-shaped steel frame 9, a steel plate 5, a sleeper 6, broken gangue 7, a spring 12, a masonry sealing wall 8, a pressure sensor 10 and the connector between them: a steel pipe sleeve 11. Bolt I17, Bolt II20. There are 10 caves 16 on the top plate 15, the bottom plate 14 and the two gangs 19 of the chamber 21, among which 3 groups (6) are arranged symmetrically on the two gangs 19, and 2 groups (4) are arranged on the top board 15 and the bottom board 14 correspondingly. ), the depth of the rock pit 16 is greater than 50cm, and the rock pit 16 on the top plate 15 and the bottom plate 14 of the chamber 21 and the rock pits 16 of the two gangs 19 are respectively in the front and rear two vertical planes, and are arranged on the bottom plate 14 top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com