Crowned tooth coupler

A coupling and drum-shaped tooth technology, which is applied in the field of drum-shaped gear couplings, can solve the problems of inconsistent specifications and models, increased spare parts, and low work efficiency, so as to improve the torque transmission effect, reduce the capital occupied by inventory, The effect of improving the fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

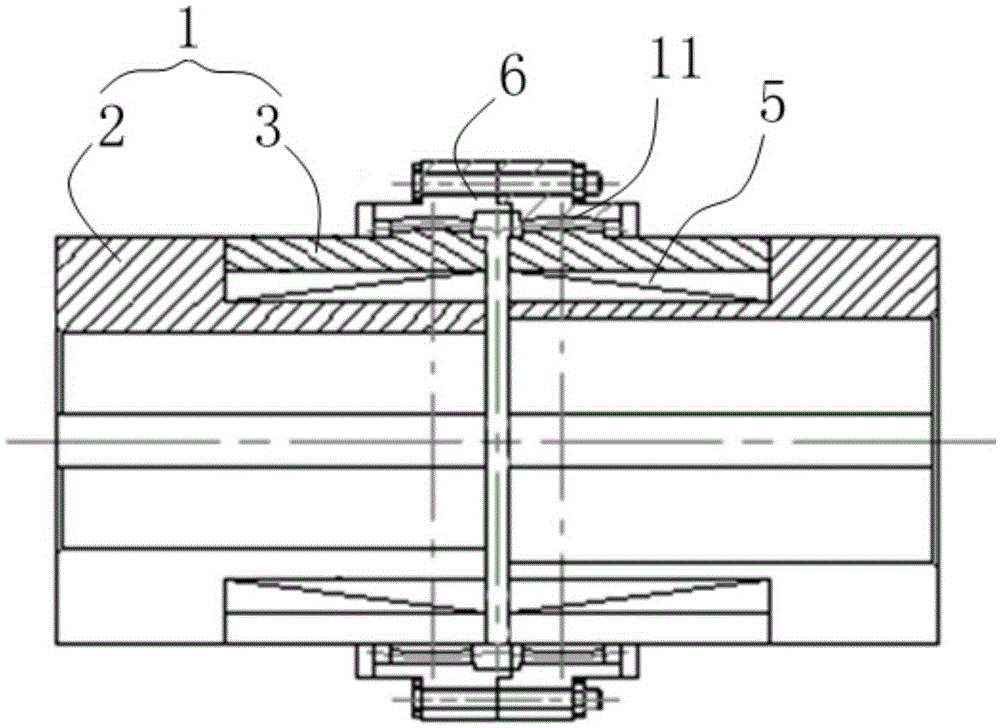

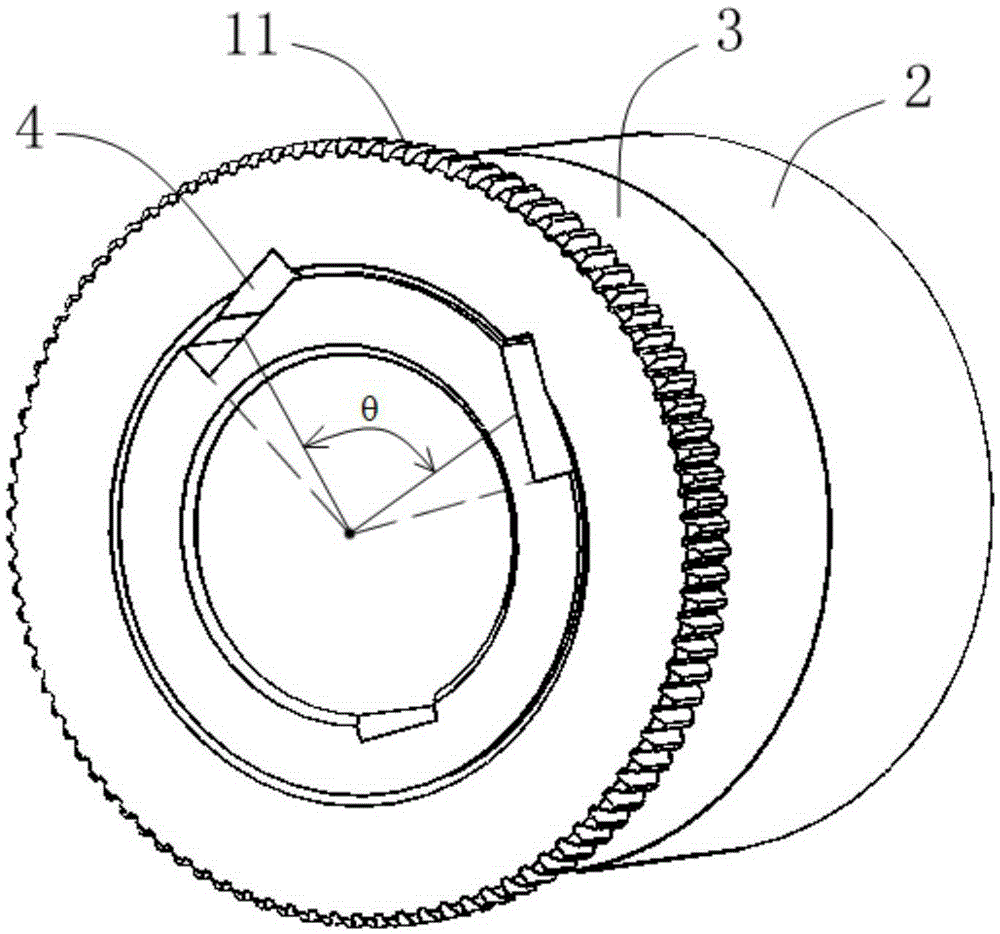

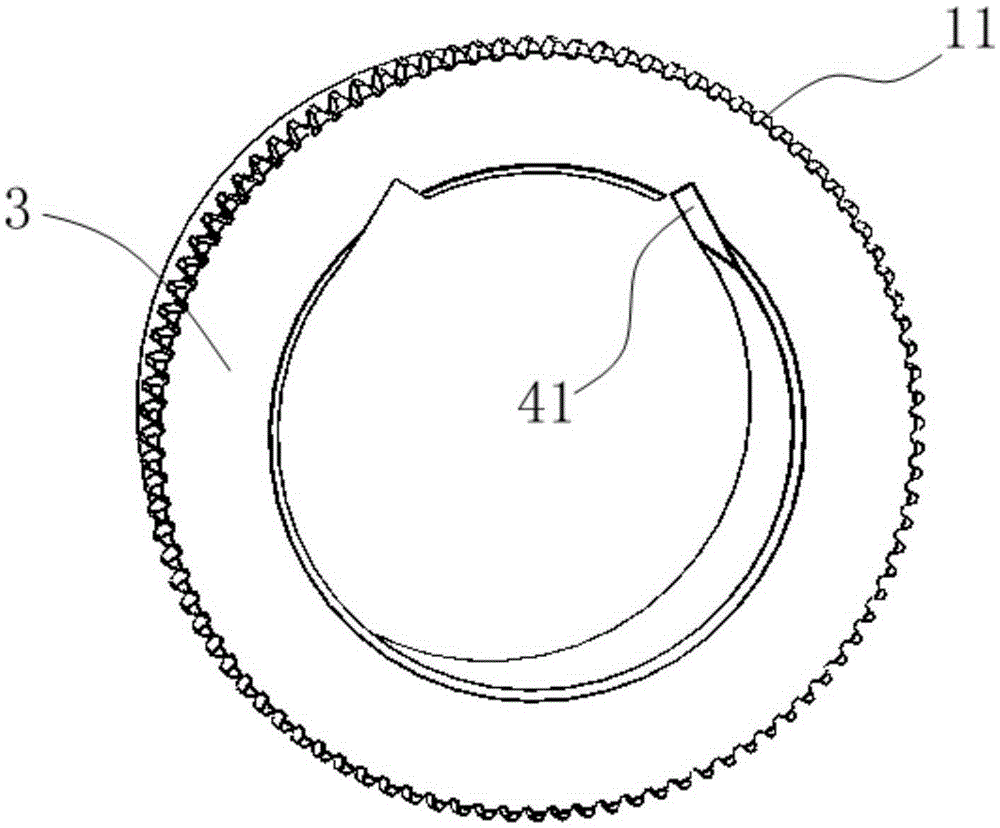

[0019] Such as Figure 1 to Figure 4 As shown in , the drum-shaped gear coupling of the present invention includes two external gear sleeves 1 arranged in mirror image symmetry, and circumferential protrusions are provided on the ends of the two external gear sleeves 1 The ring gear 11; also includes the internal gear ring 6, the internal gear ring 6 is sleeved on the ring gear 11 of the two external gear sleeves 1 at the same time, and the external gear sleeves 1 are coaxially arranged by the shaft The sleeve 2 and the external gear sleeve 3 are composed, the ring gear 11 is arranged on the external gear sleeve 3 , and the external gear sleeve 3 is detachably sleeved on the shaft sleeve 2 .

[0020] Wherein, by making the external gear sleeve 1 consist of the shaft sleeve 2 and the external gear sleeve 3 coaxially arranged, in this way, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com