Pipeline protection technology used for non-excavation penetration and urban old pipe network reconstruction

A non-excavation, urban technology, applied in the direction of pipeline protection, pipeline damage/wear prevention, pipeline laying and maintenance, etc., can solve the problems of high cost and achieve good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

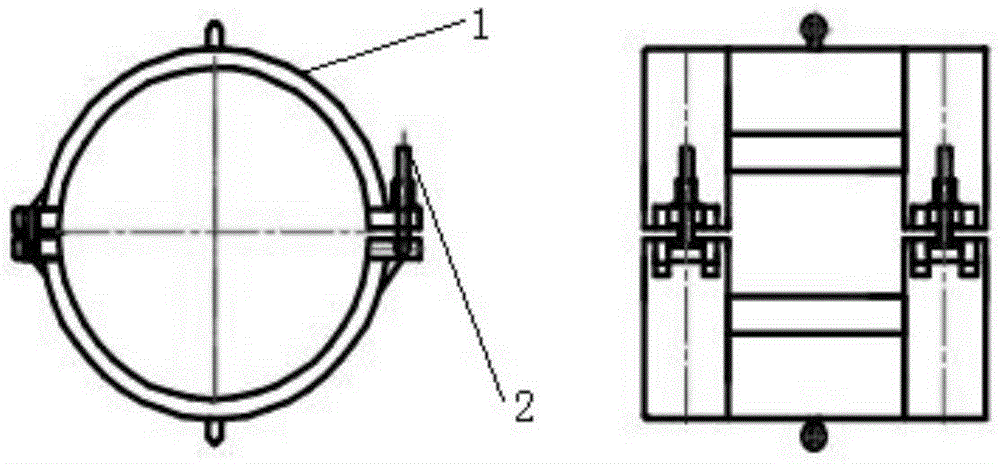

[0054] A polyethylene protective pipe used for non-excavation crossing and reconstruction of old urban pipe networks. The protective pipe is set on the outside of a plastic main pipe and is made of PE100 (RC) raw material.

[0055] The preparation method comprises the steps of:

[0056] S1. Choose a density of 950 ~ 960kg / m 3 , HDPE with a melt flow rate of 0.25-0.35g / 10min and a thermal stability of >20min at 200°C is used as raw material;

[0057] S2. Dry the polyethylene raw material described in step S1 until its moisture content is less than 150mg / kg, and then extrude, size, draw and cool; the extruder used is a single-screw extruder, and the length of the screw is The diameter ratio is set to 36, and the section between the feeding section and the plasticizing section of the extruder, and the section between the plasticizing section and the metering section are respectively provided with 2 to 3 unequal screw threads; Among them, the temperature of the feed inlet is 205...

Embodiment 2

[0060] The difference from Example 1 is that the inner diameter of the protective pipe is 1.01-1.02 times the outer diameter of the polyethylene gas pipe.

Embodiment 3

[0062] The difference from Embodiment 1 is that the polyethylene protective pipe and the plastic main pipe are fixed by welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com