Modular ceramic kiln energy-saving system of combined biomass gasifier

A technology for ceramic kilns and energy-saving systems, which is applied in the production of ceramic materials, furnaces, and furnace types, etc., can solve the problems of inability to realize gas stage regulation, inconsistent with the concept of green environmental protection, and increase equipment costs, so as to avoid air-fuel ratio imbalance. , the effect of simplifying the construction process and reducing the cost of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

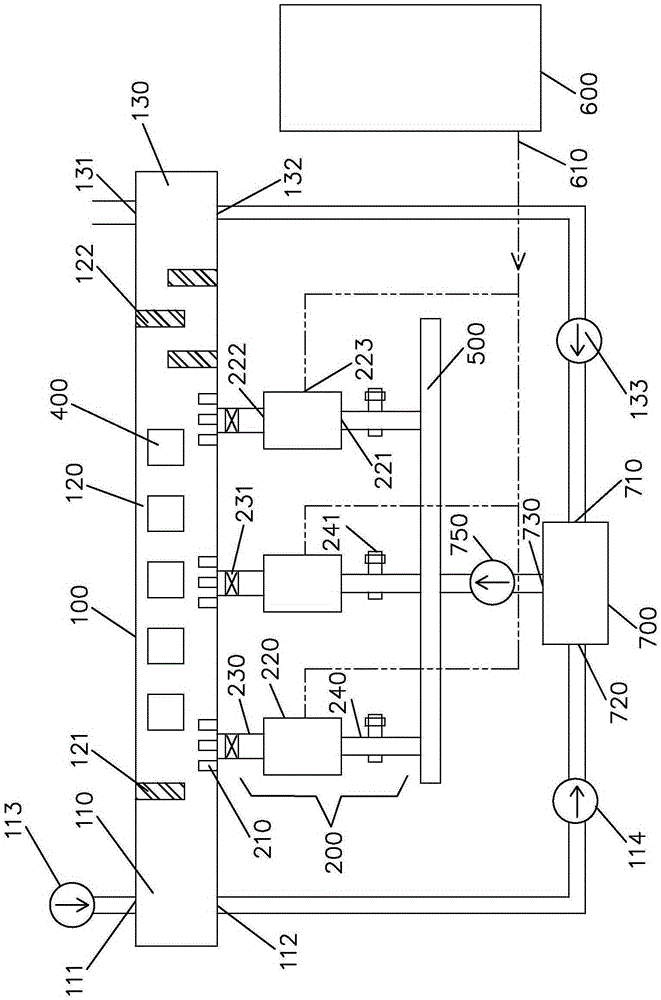

[0032] Please refer to figure 1, according to an embodiment of the present invention, a modular ceramic kiln energy-saving system combined with a biomass gasifier includes: a ceramic kiln 100 and three burner modules 200 .

[0033] Wherein, the ceramic kiln 100 is divided into a cooling section 110, a combustion section 120 and a preheating section 130 along the longitudinal direction, a first fire resistance wall 121 is arranged between the cooling section 110 and the combustion section 120, Three second fire resistance walls 122 are provided, and three burner modules 200 are connected to the side wall of the ceramic kiln 100 at equal intervals.

[0034] Wherein, the three burner modules 200 all adopt the same structure, and one of the burner modules 200 is used as an example for illustration below.

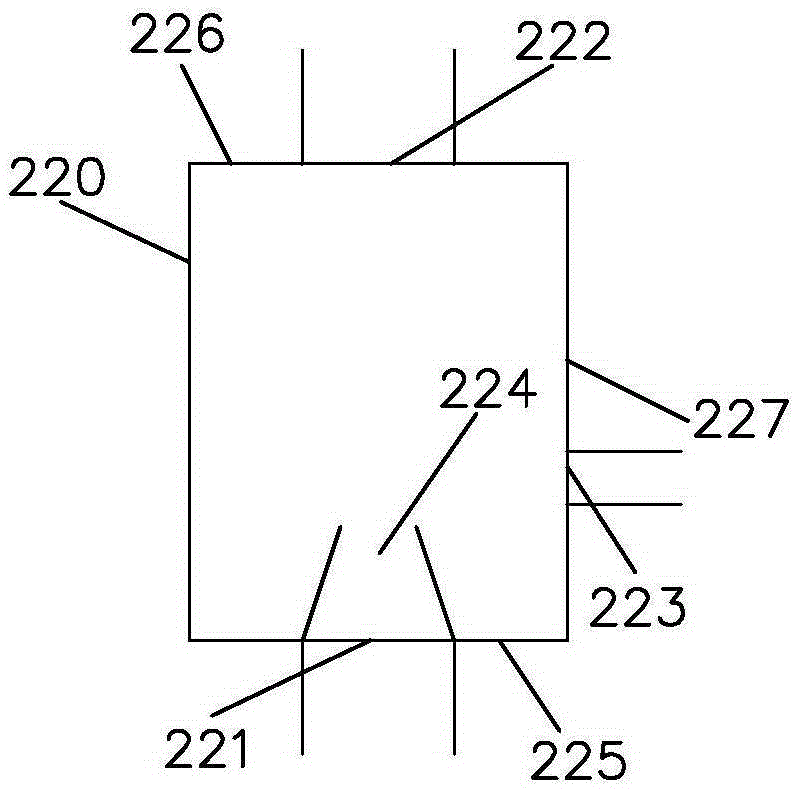

[0035] The burner module 200 includes: three burners 210 , an injection mixer 220 , a first connecting pipe 230 and a second connecting pipe 240 . The three burners 210 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com