Food contact material single-face soaking device

A single-sided technology for food contact materials, applied in measurement devices, analytical materials, surface/boundary effects, etc., can solve the problems of large error in test results, complicated and cumbersome operations, inaccurate test results, etc., and achieve small error in measurement results, Accurate soaking area and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

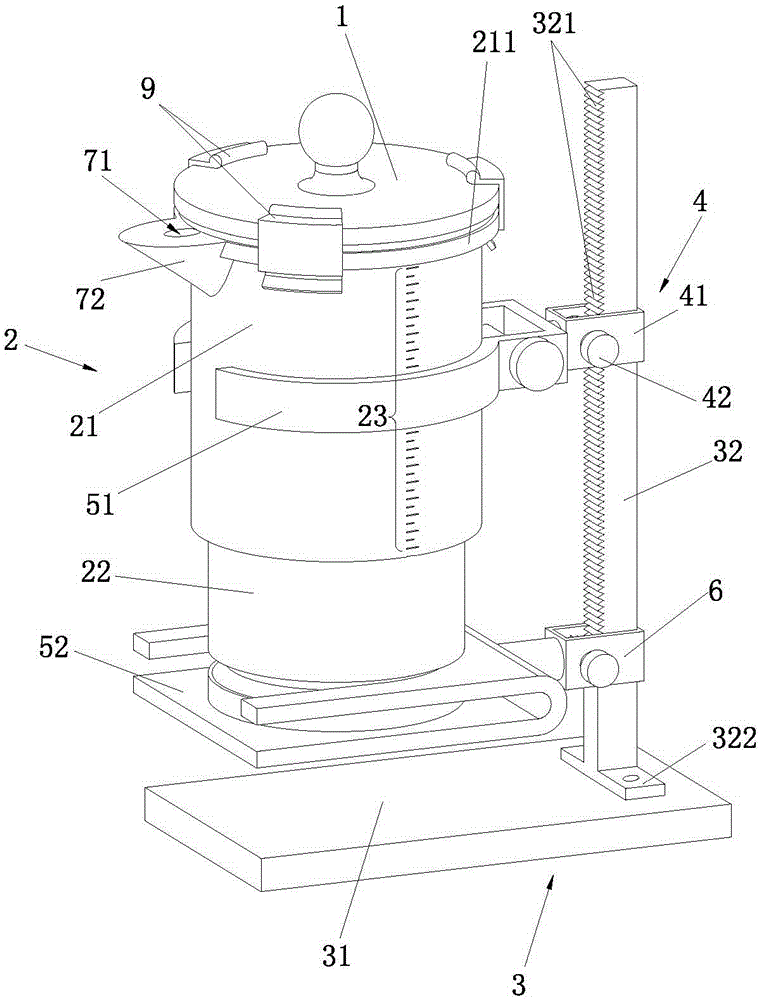

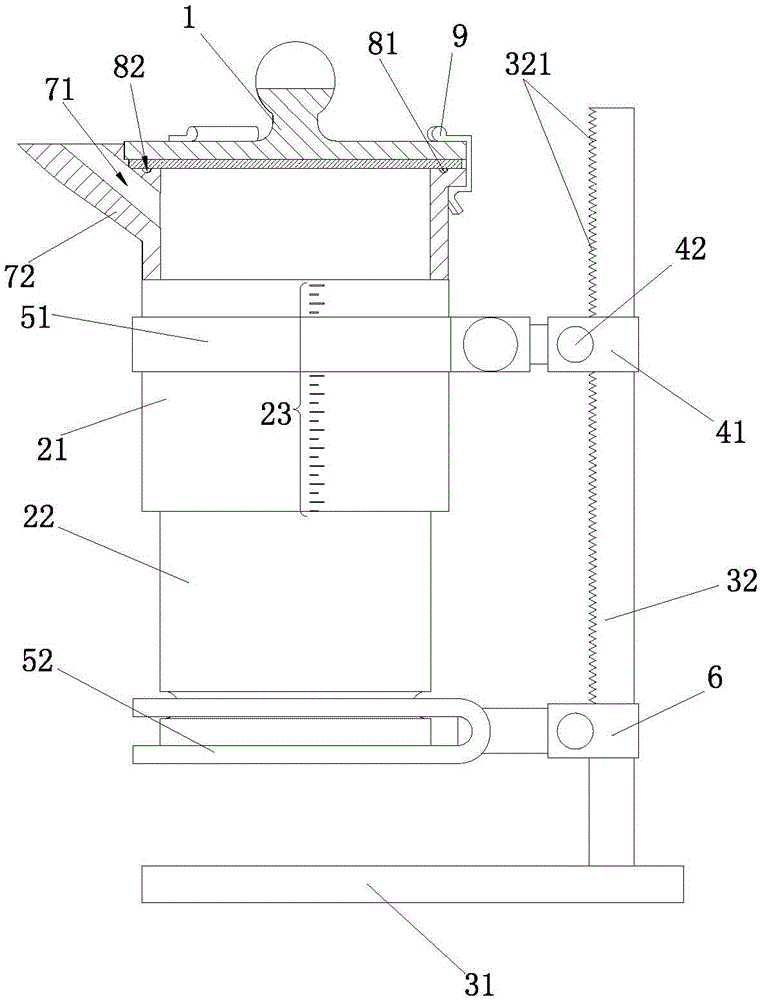

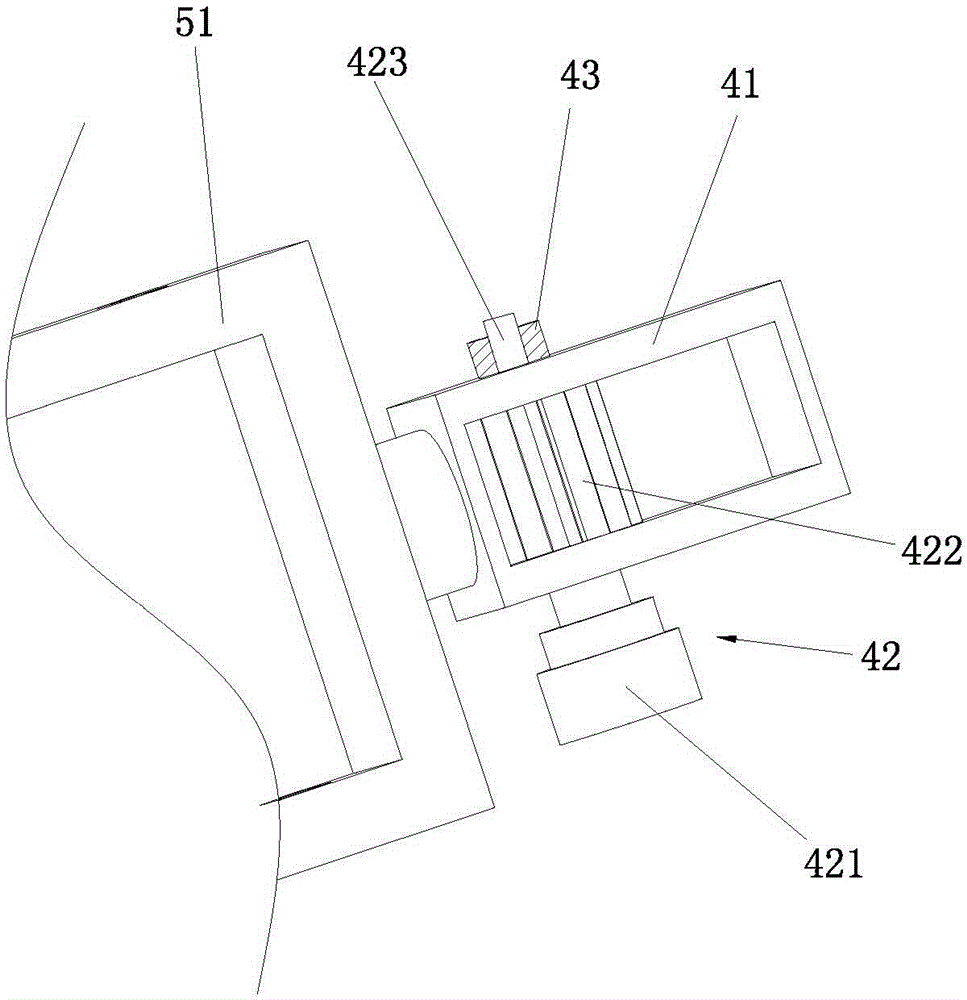

[0043] Such as Figure 1 to Figure 3 As shown, a food contact material one-sided soaking device of the present invention includes a sealing cover 1 and a container body 2 for containing the soaking solution, and the sealing cover 1 is detachably arranged on the opening of the container body 2 The storage bottle 2 includes a storage tube 21 and an adjustment body 22 for adjusting the volume of the storage bottle 2. The adjustment body 22 is slidably arranged inside the storage tube 21 or connected to the storage tube through threads. 21 connections. The sealing cover 1 is mainly used to press the food contact material to be tested on the opening end of the container body 2, and at the same time avoid the volatilization of the soaking solution. The sealing cover 1 can be connected to the opening end of the container body 2 through threads, or can Other fastening devices are fastened to the opening end of the container body 2; when testing, first fill the container body 2 with t...

Embodiment 2

[0057] Such as figure 1 , 3 , 4, the difference between this embodiment and the first embodiment is that it also includes a second sealing ring 83 arranged between the sealing cover 1 and the container body 2, the second sealing ring 83 and the first sealing ring 81 Coaxial and adjacently arranged, the sealing cover 1 is provided with a second ring groove 84 for fixing the second sealing ring 83; the second sealing ring 83 is used to further improve the sealing effect of the device, and the second sealing ring 83 is clamped or glued Connected to the second ring groove 84; since the second sealing ring 83 is coaxial and adjacent to the first sealing ring 81, when soaking, the edge of the food contact material to be tested is clamped between the first sealing ring 81 and the second sealing ring. Between the rings 83, thereby greatly improving the sealing effect of the device, further avoiding easy volatilization after soaking, and further reducing measurement errors.

[0058] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com