Rotary detection device for steel ring welding

A technology of welding inspection and detection device, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of low reliability and non-destructive testing of welds, and achieves fast welding speed, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

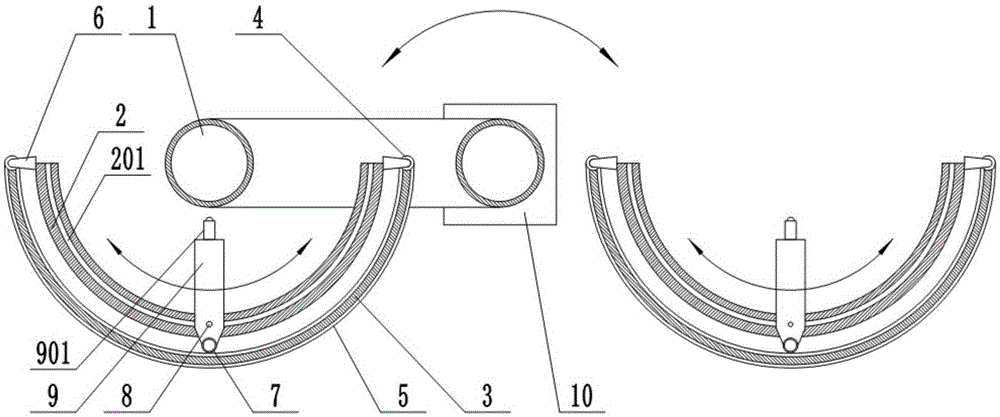

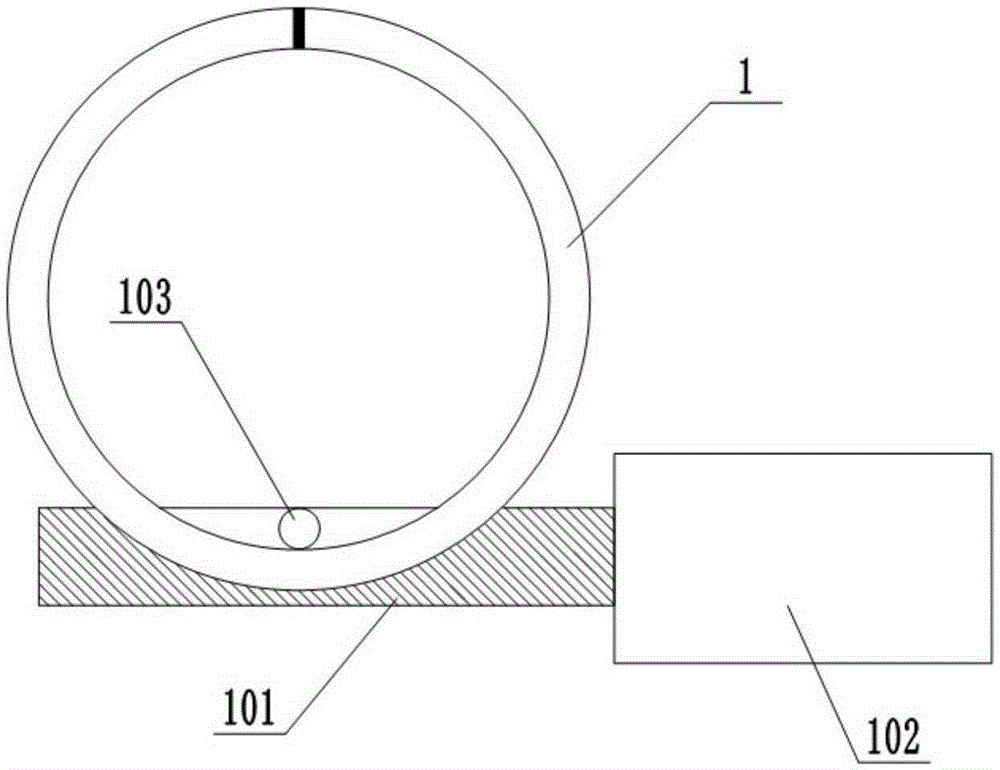

[0012] Such as figure 1 , figure 2 As shown, the rotating steel ring welding detection device of this embodiment includes a rotating support base 10 and arc-shaped guiding detection devices located symmetrically on both sides of the rotating support base 10; the rotating support base 10 includes a clamping base 101 and a rotating oil cylinder 102 The steel ring 1 is installed on the clamping seat 101 through the clamping rod 103, and the steel ring 1 swings 180 degrees between the two arc-shaped guide detection devices through the rotating support base 10; the arc-shaped guide detection device includes an arc-shaped guide device and welding The seam detection head 9 is slidably installed in the arc-shaped guide device, and the ultrasonic detection end 901 at the inner end of the weld seam detection head 9 faces the center of the arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com