Large transformer lead assembly method

An assembly method and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems that the assembly method cannot realize programmed operation, parallel assembly and assembly processes, and long production cycle. Shorten production cycle, facilitate standardization, improve assembly quality and the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

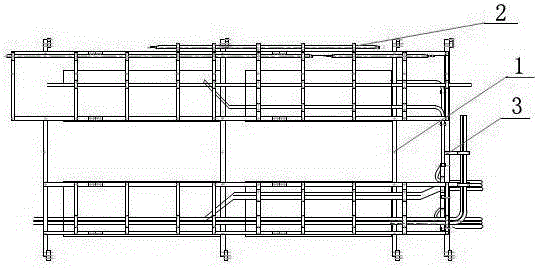

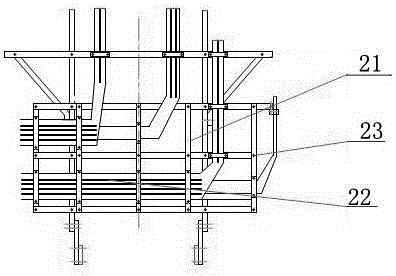

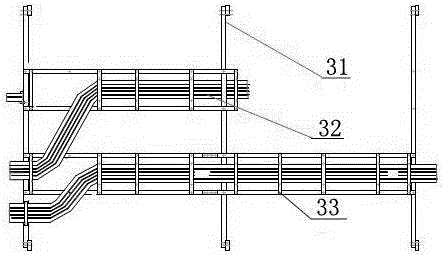

[0018] A large-scale transformer lead wire assembly method, which is divided into three modules according to the lead wire structure, high-voltage lead wire clip and lead module, voltage regulating wire clip and lead module, switch wire clip and lead module, when assembling the transformer body, according to the drawing in advance The independent assembly of the three modules is carried out independently. After the independent assembly of the three modules is completed, they are connected to the transformer body as a whole, and the assembly of the transformer body is carried out at the same time to complete the assembly of all transformer leads. The specific process steps are as follows:

[0019] Assemble the high-voltage lead wire clip and lead wire module, and according to the design requirements for assembling the high-voltage lead wire of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com