A 12/14 Bearingless Switched Reluctance Motor with Adjustable Air Gap

A switched reluctance motor, adjustable technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of few rotor poles and low power density, reduce copper consumption, improve power density, and reduce coil current. and the effect of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

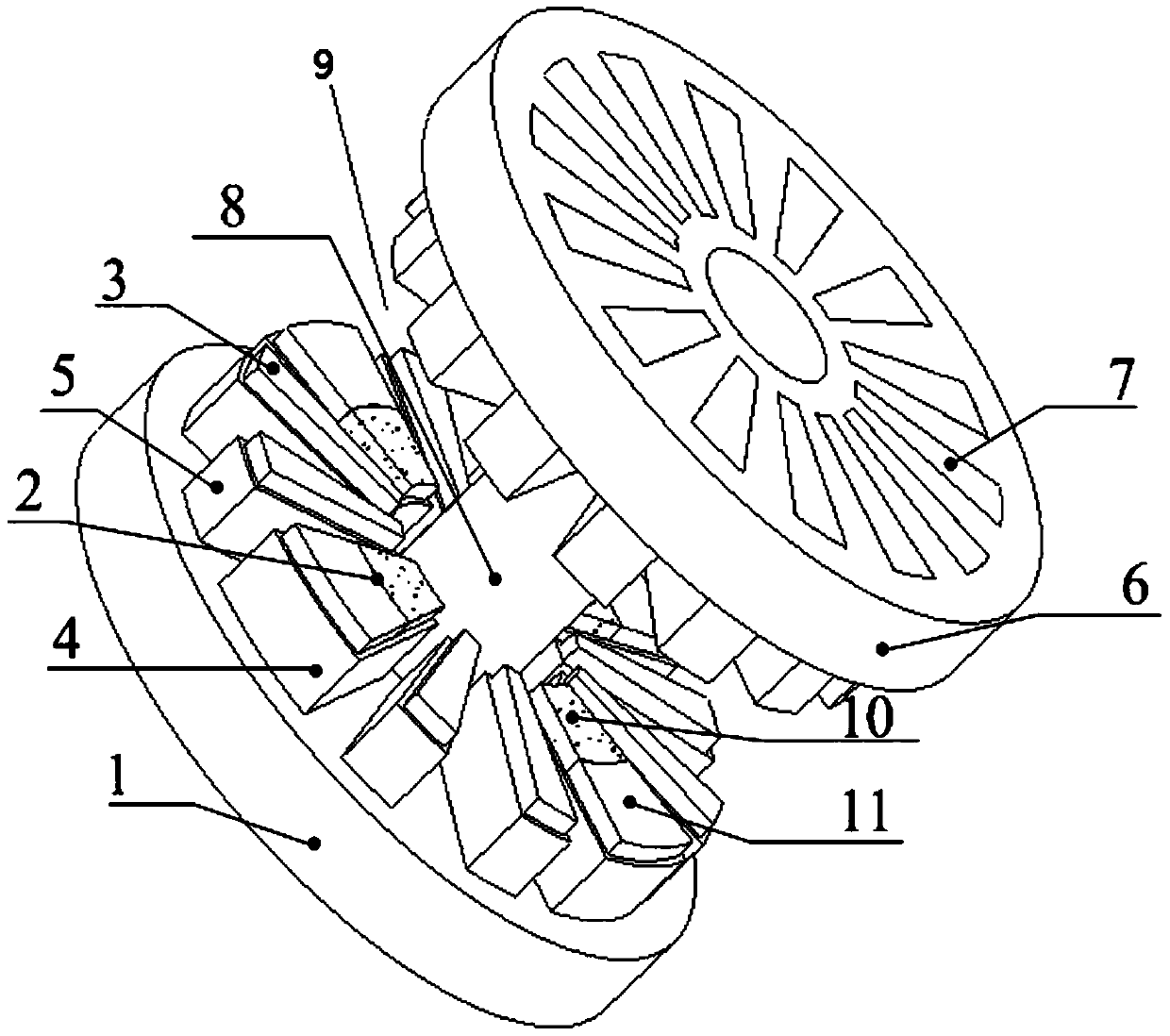

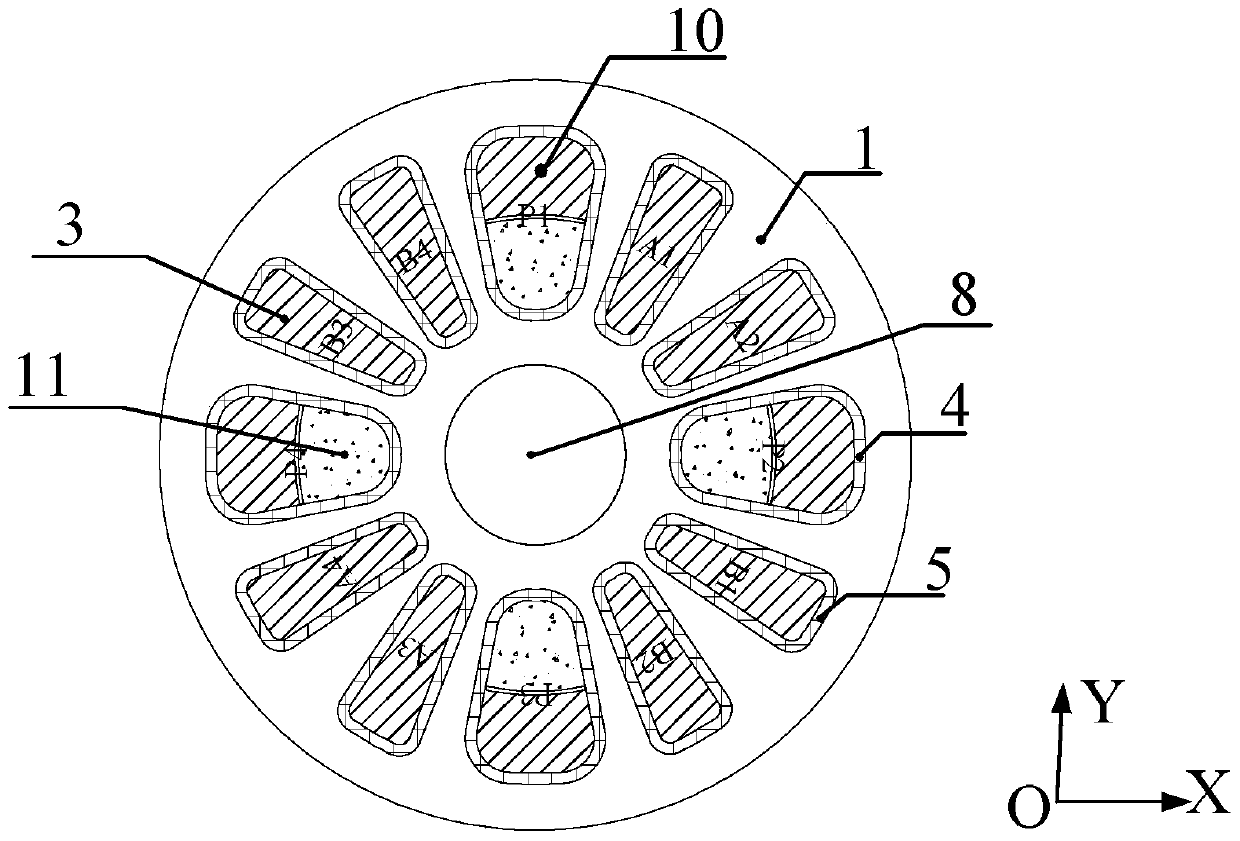

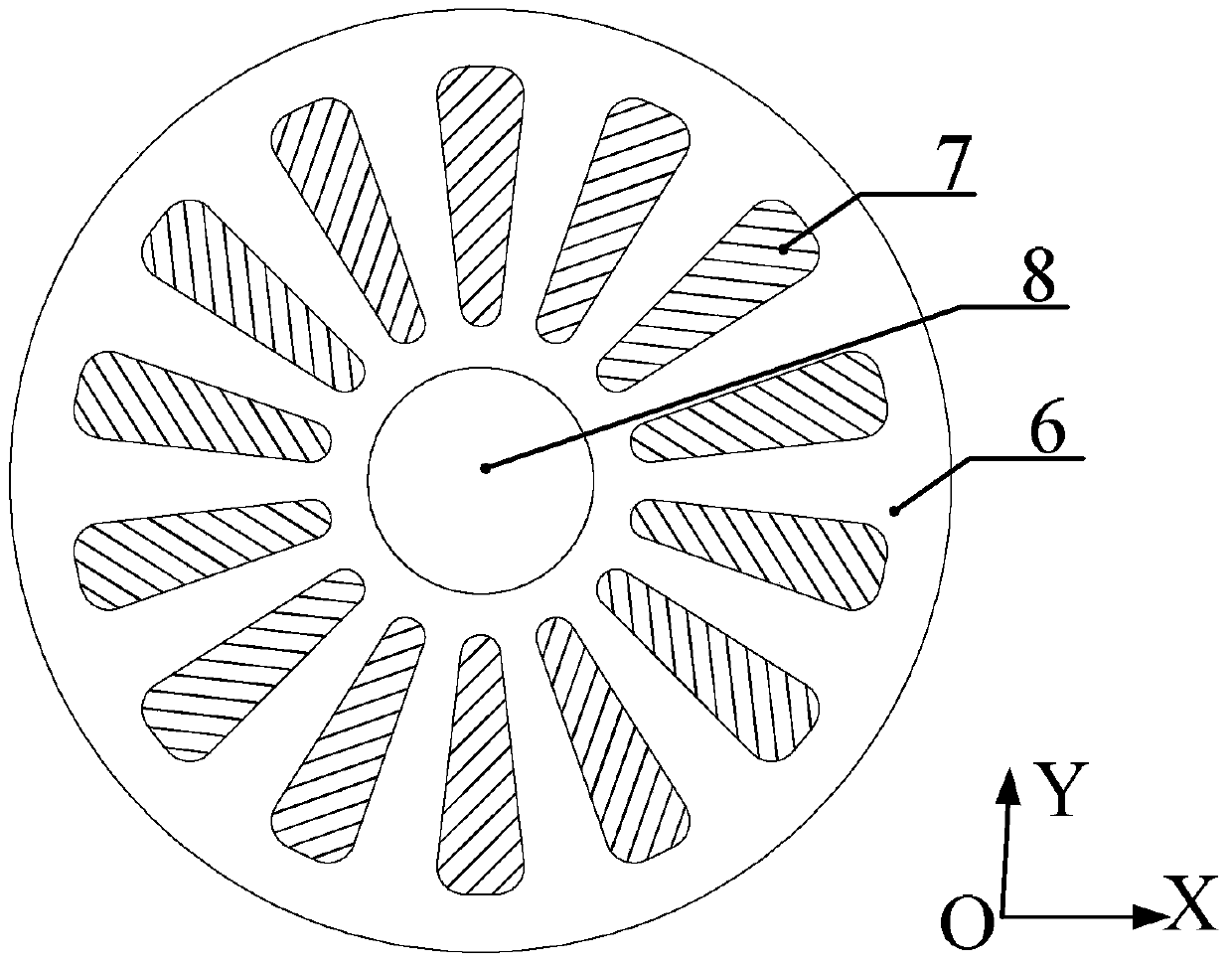

[0024] Such as Figure 1~5 As shown, a 12 / 14 bearingless switched reluctance motor with an adjustable air gap includes a rotor core and a stator core, the rotor core is connected to the stator core through a shaft 8, and the rotor core includes a rotor Yoke 6 and rotor pole teeth 7, wherein the rotor yoke 6 is located at the bottom end, and the upper end of the rotor yoke 6 is inlaid with 14 evenly distributed rotor pole teeth 7, and the stator core includes the uppermost stator yoke 1, which is inlaid on the stator yoke The 4 stator auxiliary magnetic pole teeth 2 and 8 stator torque magnetic pole teeth 3 below 1, the stator auxiliary magnetic pole teeth 2 include the adjustment magnetic pole teeth 11 and the permanent magnets 10 that are close to the inner side of the stator auxiliary magnetic pole teeth 2, the stator auxiliary magnetic pole teeth An auxiliary adjustment coil 4 is wound on the tooth 2 , and a torque winding coil 5 is wound on the stator torque magnetic pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com