Contactless guide rail dedusting device

A dust removal device and non-contact technology, applied in the field of machine tool guide rails, can solve the problem of large occupation of protective cover space, and achieve the effects of reducing the difficulty of processing and manufacturing, reducing product models, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

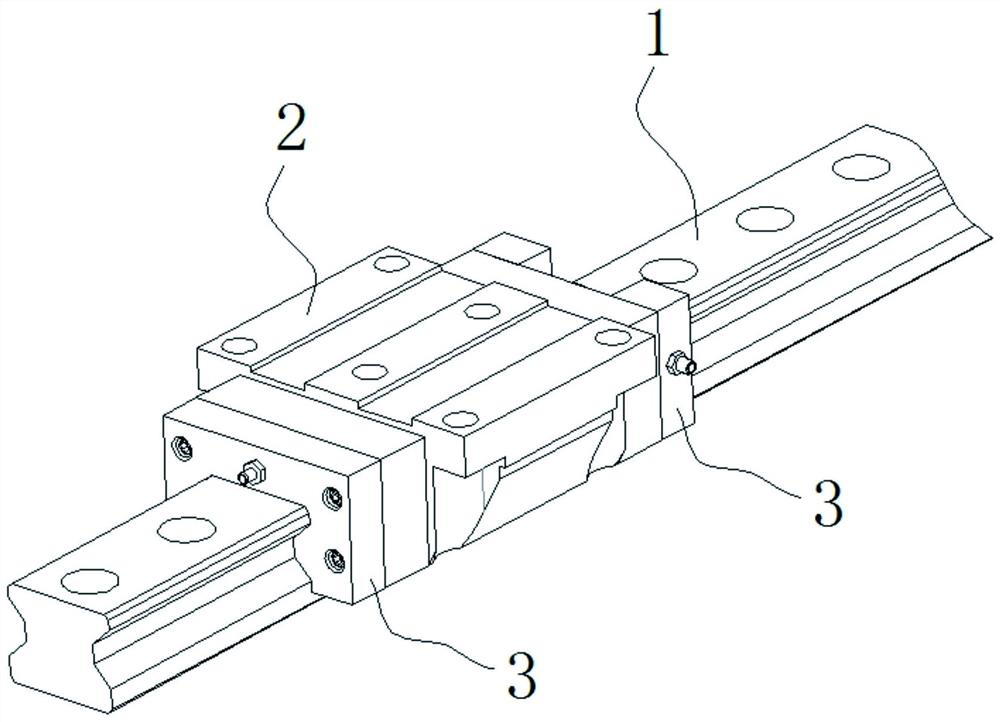

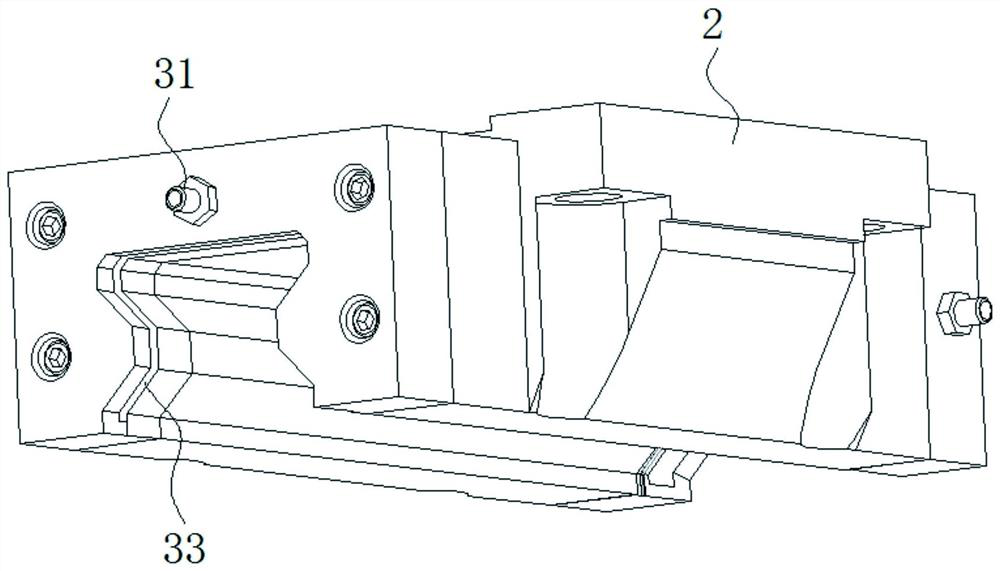

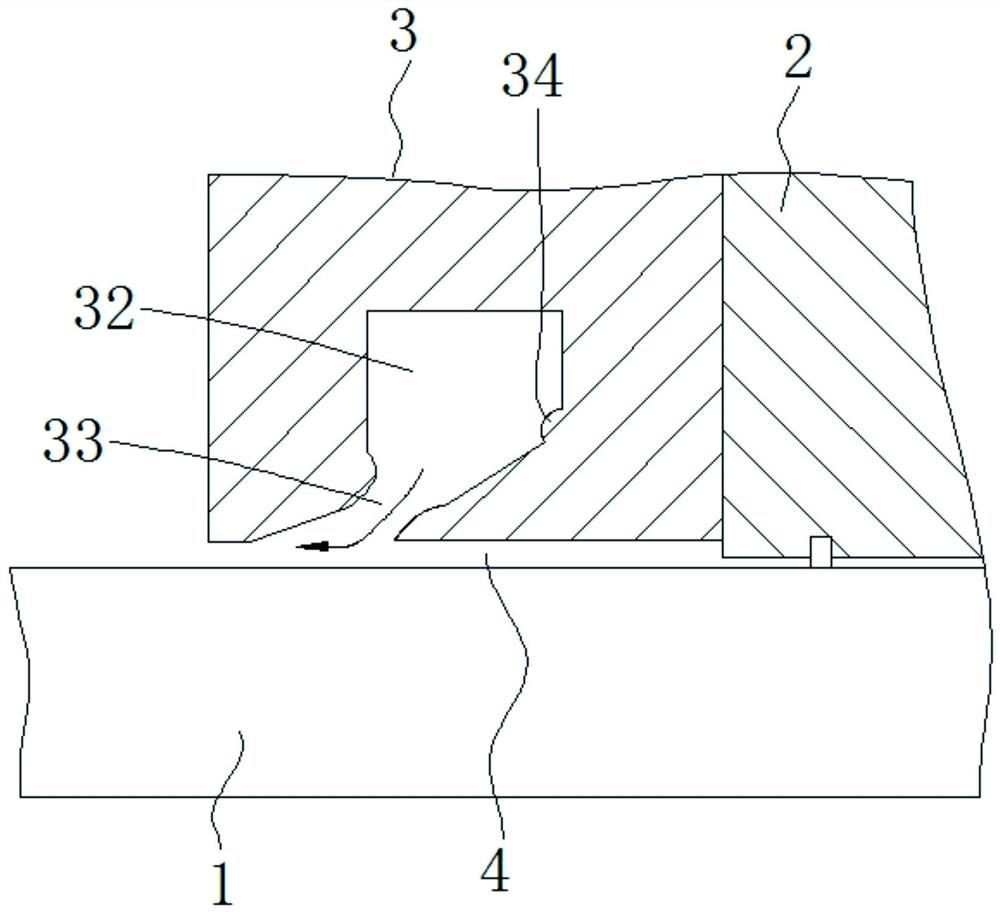

[0028] A non-contact guide rail dust removal device, such as Figure 1-3 As shown, as an optional accessory of the guide rail slider assembly, it is installed on the end face of the slider 2 and forms a groove-shaped gap 4 equidistant from the working surface of the guide rail. The guide rail dedusting device 3 is provided with an air inlet 31 , an air chamber 32 and an air injection port 33 . Specific instructions are given below.

[0029] Such as image 3 As shown, the air inlet 31 is connected to an air source through a reversing valve, and is used for introducing high-pressure air into the air cavity 32 . The air injection port 33 has a shape suitable for the cross-sectional shape of the guide rail, and forms an equidistant groove-shaped slit 4 with the special-shaped working surface of the guide rail, and the slit width of the groove-shaped slit is 0.15mm. Since the air jet has a closing structure, the flow rate of high-pressure air can be further increased. The air i...

Embodiment 2

[0036] Different from Example 1, as Figure 5 As shown, the guide rail dedusting device 3 is composed of two split parts connected by bolts. A gasket 5 is additionally installed between the two split parts, and the gasket 5 is used to adjust the slit width of the air outlet side of the slot-shaped slit 4 . Such a design, firstly, realizes the adjustment of the groove-shaped gap 4; secondly, separate processing reduces the processing difficulty of the air cavity 32 and the air injection port 33 . Obviously, such a design does not require mold opening, which is beneficial to the small-batch machining production of the present invention.

[0037] In the above two embodiments, although the air consumption of the guide rail dedusting device 3 is not large, the total air consumption is still very large in the case of a long working time. Therefore, the technical solution is further improved: the air inlet 31 on each rail dedusting device 3 is connected to the air source through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com