A foam aluminum electromagnetic shielding splicing board

A foam aluminum plate, electromagnetic shielding technology, applied in magnetic field/electric field shielding, electrical components, projection room/room, etc., can solve the problems of complicated welding seam method, restricting the application of foam aluminum, low welding seam strength, etc. The effect of cost reduction, improved electromagnetic shielding performance, and low splicing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

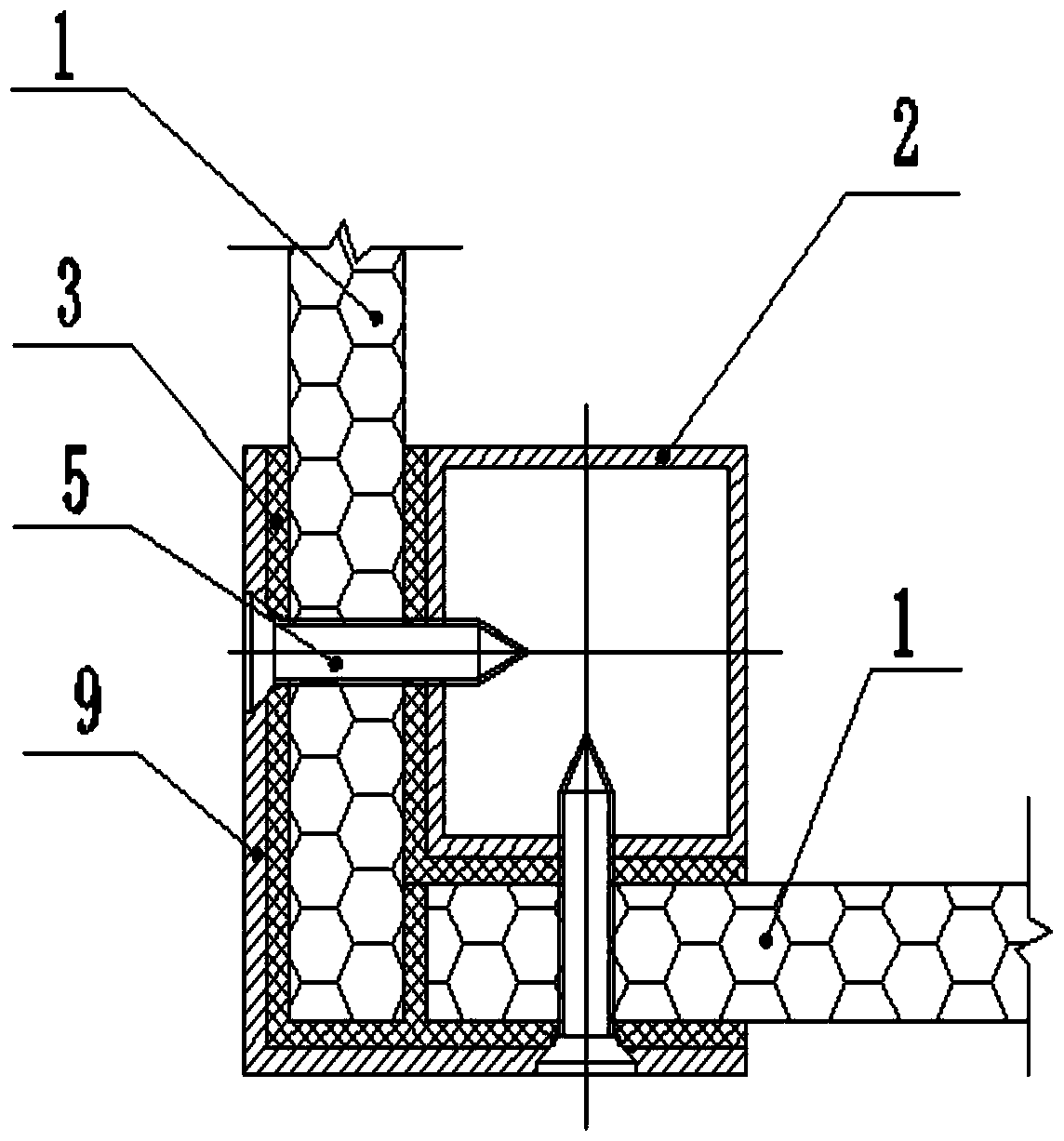

[0022] image 3 Shown is the third embodiment of the present invention, the technical solution of the third embodiment is to vertically splice two foamed aluminum plates 1, the foamed aluminum plates after splicing form a right angle, and the foamed aluminum plates form a right angle One side of the positive angle is provided with a right-angle type seam pressing plate 9. A keel is arranged on one side of the internal angle formed by the foamed aluminum plate. The shielding interlayer special-shaped part 3 is two vertically connected double U-shaped structures, and the double U-shaped structure is decomposed into two U-shaped structures 11 with the interlayer 6 of the shielding interlayer special-shaped part as the dividing line, and each U-shaped structure 11 The outer layer 12 wraps the edge of every foamed aluminum plate. The right-angle joint pressing plate 9, the shielding interlayer special-shaped part 3, the foamed aluminum plate 1 and the keel 2 are fixed with screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com