Vehicle seat

A vehicle seat and seat technology, applied in the direction of vehicle seats, seat frames, vehicle parts, etc., can solve the problems of unsuitable road vehicles, low adjustability, comfort and accessibility, etc., and achieve improved static Effects of stability, reduced section thickness, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this application, references to directions such as fore / aft, vertical, inwardly, laterally, etc. are all intended to be interpreted relative to the seat itself. No ambiguity arises as a person sits in a defined position in which their legs protrude in the forward direction. Seats are normally installed in vehicles facing forwards, so the same directional indications will generally likewise apply with respect to the vehicle. However, it is permissible to mount the seat in a rearward facing orientation, so it is likely that the orientation will be reversed relative to the vehicle in question.

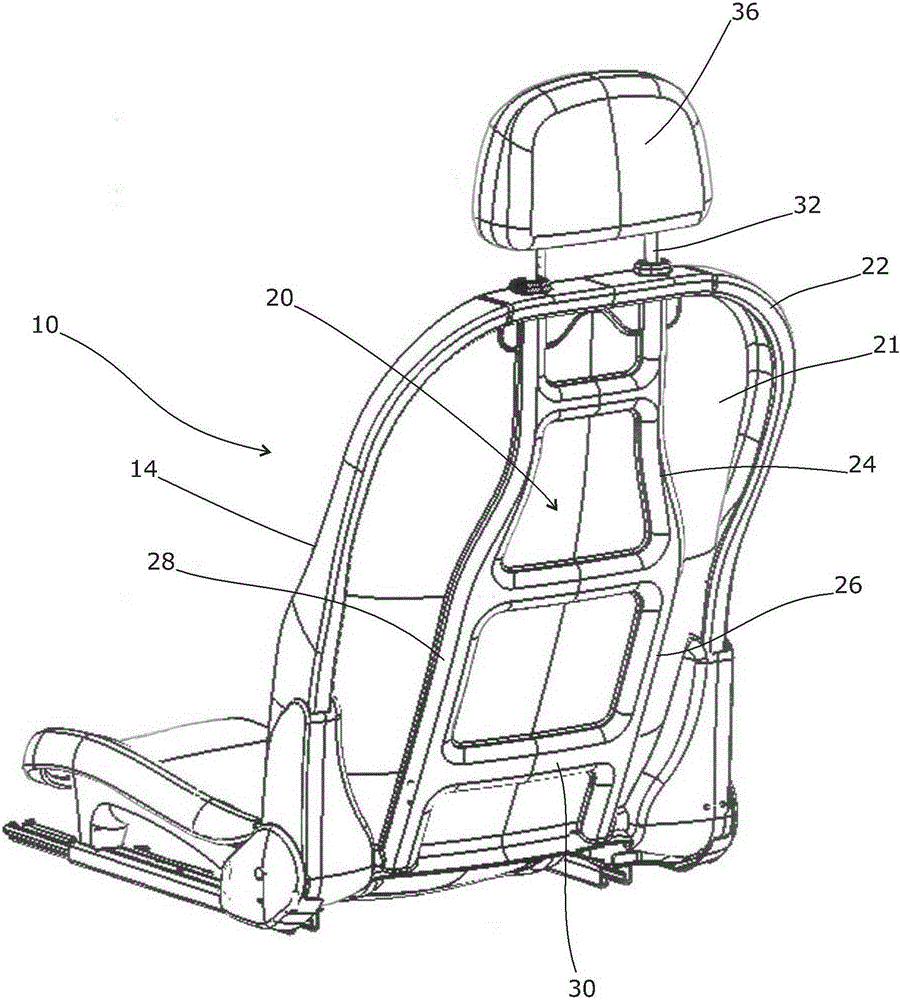

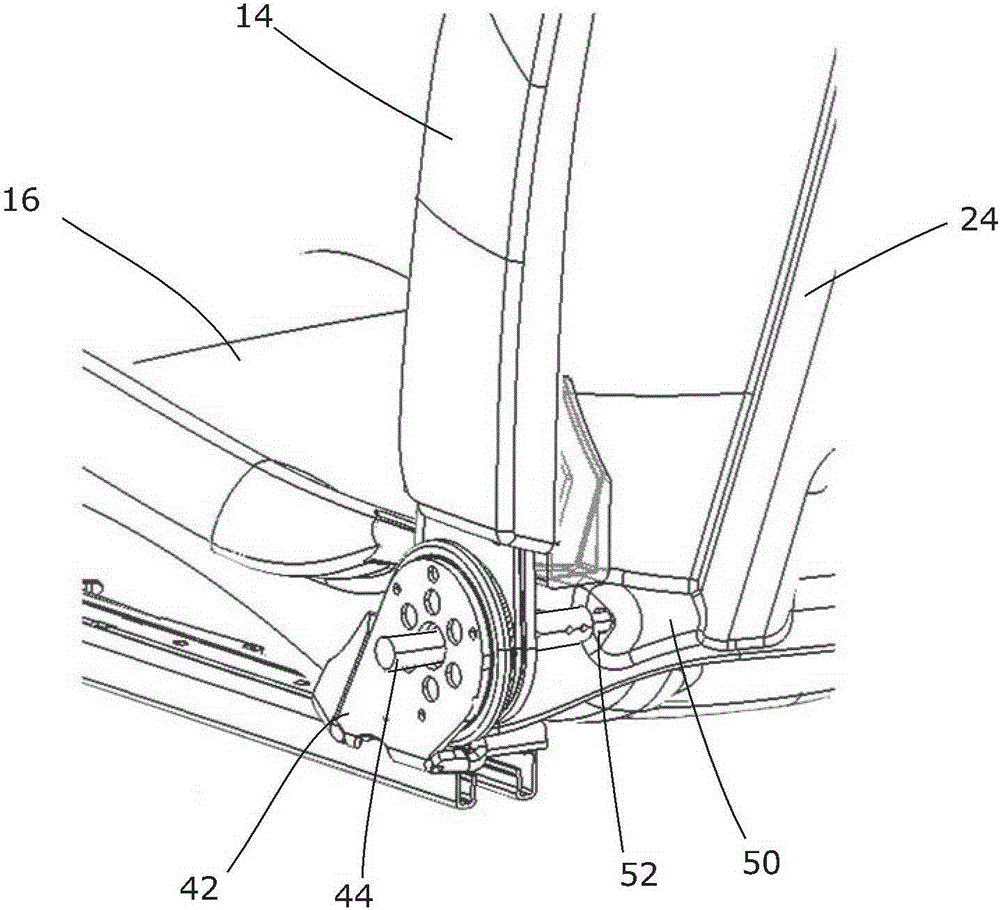

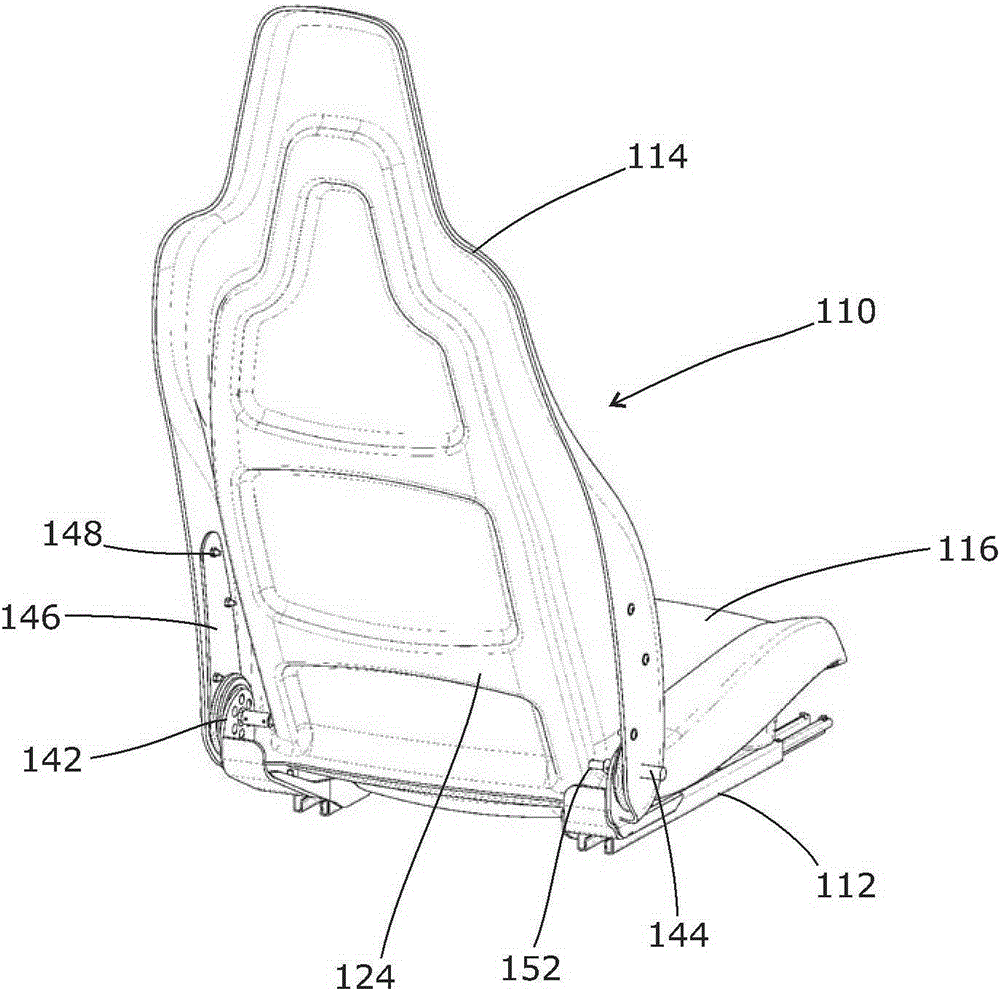

[0026] refer to figure 1 , the vehicle seat 10 is composed of three main parts, a base unit 12 , a seat back 14 and a seat base 16 . The base unit 12 includes a pair of front and rear adjustable runners 18 of conventional design by which the base unit 12 is attachable to a suitably solid portion of the floor of the vehicle. The seat back and seat base are molded composite pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com