Automatic soup feeding system controlled by casting servo

A servo control and soup feeding technology, which is applied in the field of soup feeding system and automatic soup feeding system, can solve the problems of low efficiency, high labor intensity, unstable product quality, etc., to facilitate product replacement, improve production efficiency, and reduce heat preservation furnace and artificial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

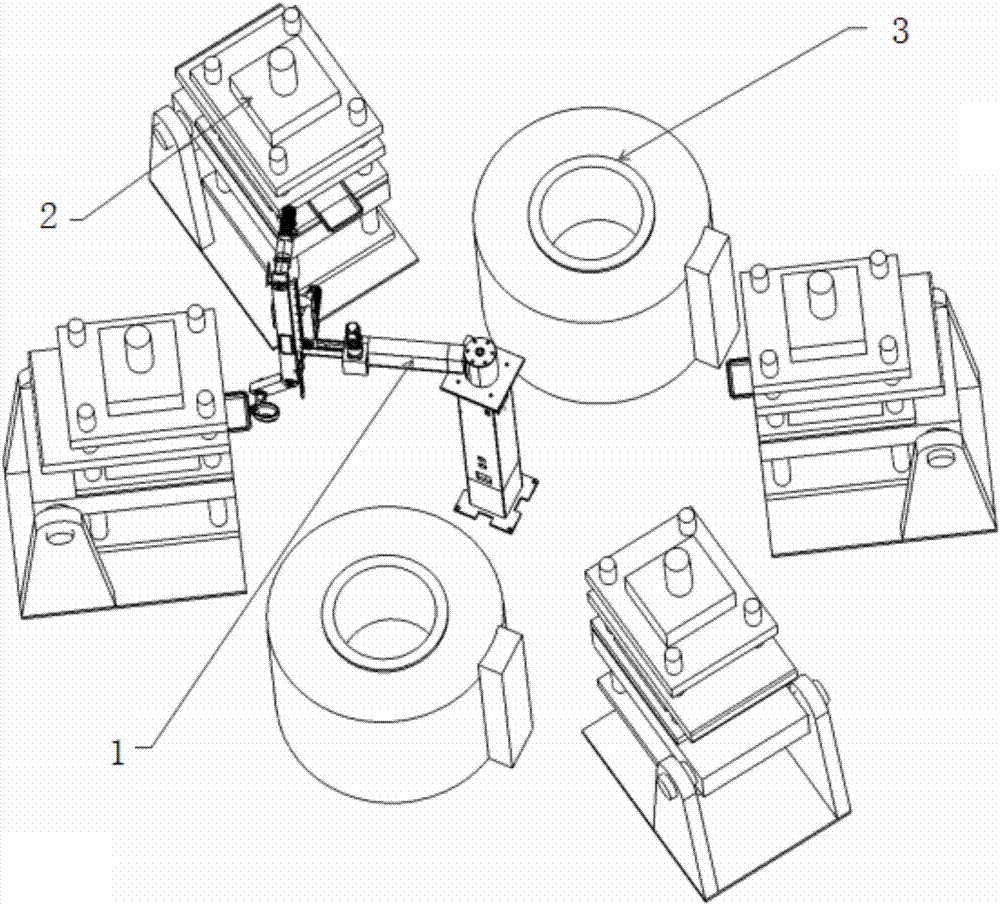

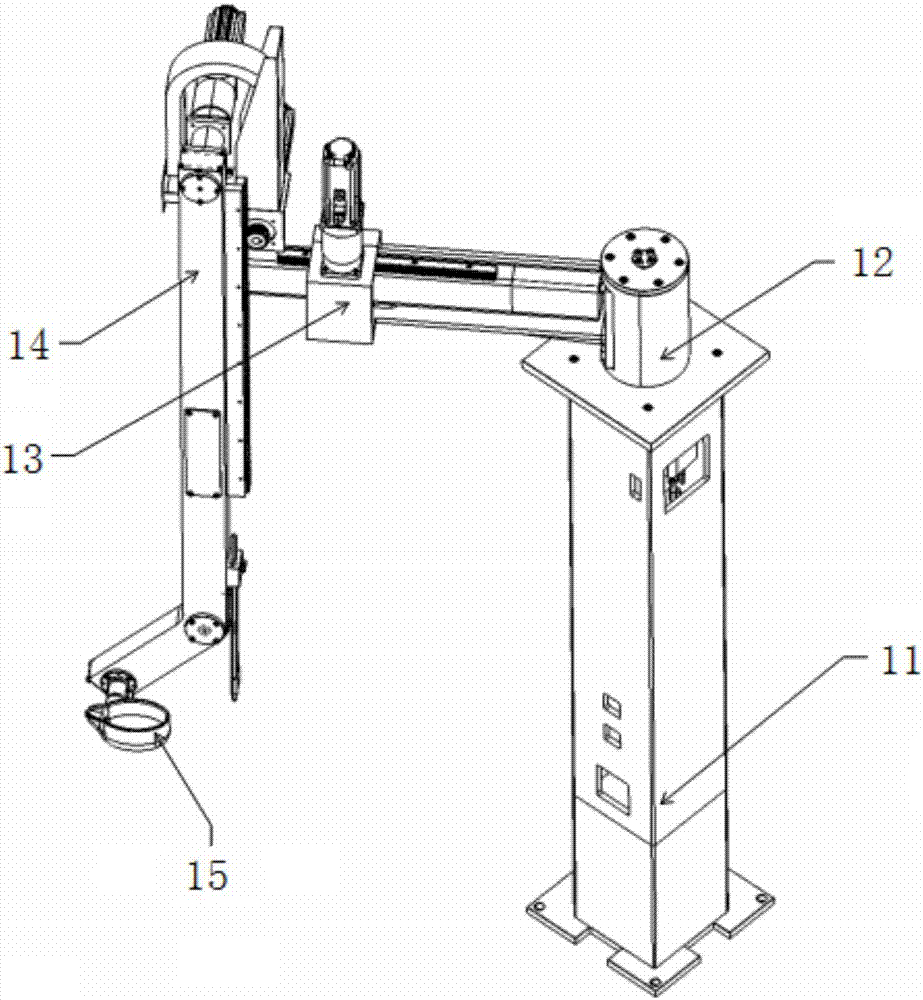

[0024] see figure 1 , the present invention discloses a casting servo-controlled automatic soup feeding system, which consists of soup feeding machine 1, soup liquid holding furnace 2, pouring equipment 3, control cabinet, safety guardrail and operation panel, etc., soup liquid holding furnace 2 and The pouring equipment 3 presents a circular distribution with the soup dispenser 1 as the center, and the system is composed of the soup dispenser 1 with full servo control located in the center, and the soup dispenser 1 spoon arm moves up, down, and retracts according to the program instructions. , Stretch, and rotate to realize taking soup (casting solution) from the holding furnace----supplying soup to multiple casting machines respectively-repeating cycle, realizing continuous and precise positioning of multiple casting equipment 3 around the circumference to supply soup.

[0025] Various actions of the soup dispenser 1 are driven by servo motors, and the whole system is contro...

Embodiment 2

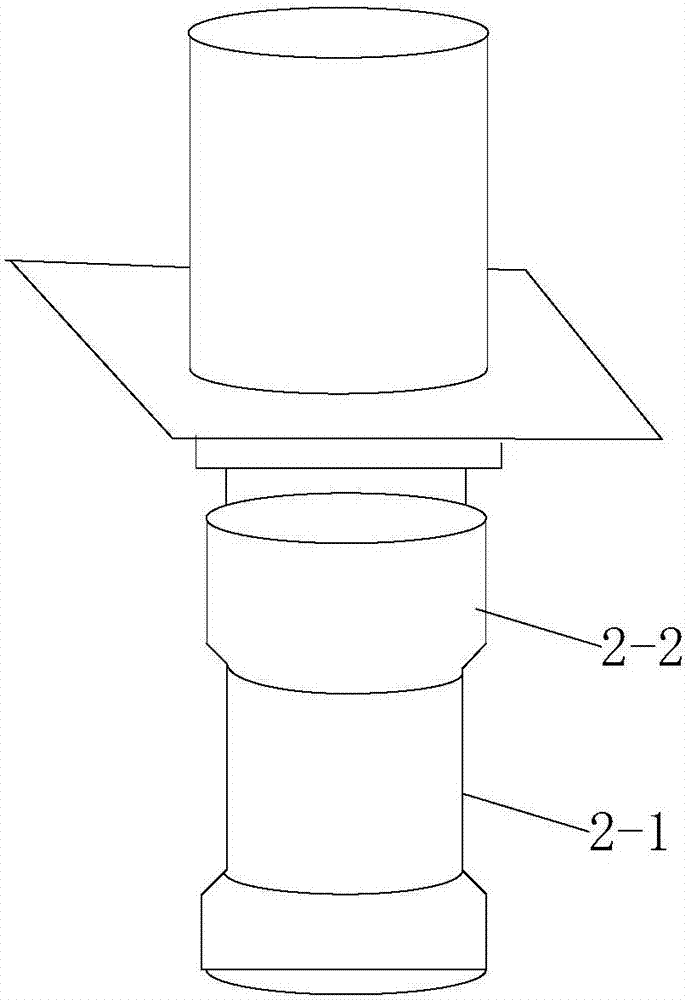

[0027] see figure 1 , an automatic soup feeding system controlled by casting servo, the system includes: a soup feeding machine 1, at least two soup holding furnaces 2, at least two pouring equipment 3, a control cabinet, a safety guardrail, and an operation panel. Each soup holding furnace 2 and pouring equipment 3 are respectively distributed around the soup dispenser 1; the operation panel is connected to the control cabinet, and the control cabinet is connected to the soup dispenser 1; the control cabinet controls 1 spoon of the soup dispenser with full servo control The up and down movement, stretching, and rotation of the arm realizes taking soup from the holding furnace, feeding soup to each casting machine separately, and repeating the cycle, so as to realize the continuous and precise positioning of multiple casting equipment 3 around the circumference and feeding soup; the soup feeding machine 1 Various actions are driven by servo motors; at least two soup holding fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com