Tire blank unloading device for tire industry forming machine

A molding machine, an industry-leading technology, applied in the direction of lifting devices, tires, applications, etc., can solve problems such as heavy weight, lower yield, and complex specifications, so as to reduce the deformation of the tire blank, the process of unloading the tire is stable, and the swing angle can be adjusted. tune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

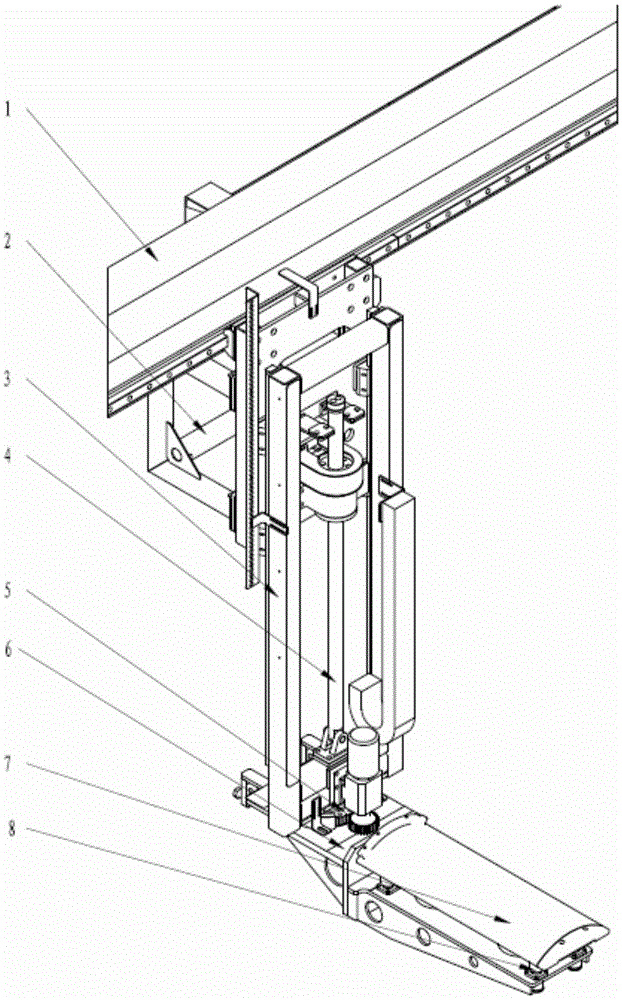

[0012] see figure 1 , the tire blank unloading device for the tire industry building machine of the present invention includes a crossbeam 1, a lateral moving frame 2, a longitudinal moving frame 3, a steering seat 6 and a profiling support plate 7 for supporting the tire blank, and the crossbeam 1 is used as a basis The frame is connected to the ground, and the laterally moving frame 2 is installed on the beam 1 through a slider, and the laterally moving frame 2 can move laterally relative to the beam 1 through a power device, and the longitudinally moving frame 3 is installed on the horizontally moving frame through a linear slide rail. on the frame 2, and the longitudinal moving frame 3 can move up and down relative to the lateral moving frame 2 through the driving mechanism, and the bottom of the longitudinal moving frame 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com