Retrieval box device

A technology of trays and shafts, applied in the field of tray-taking devices, can solve problems such as complex control systems and complex structures, and achieve the effects of improving production efficiency, reducing labor costs, and reducing the number of production workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

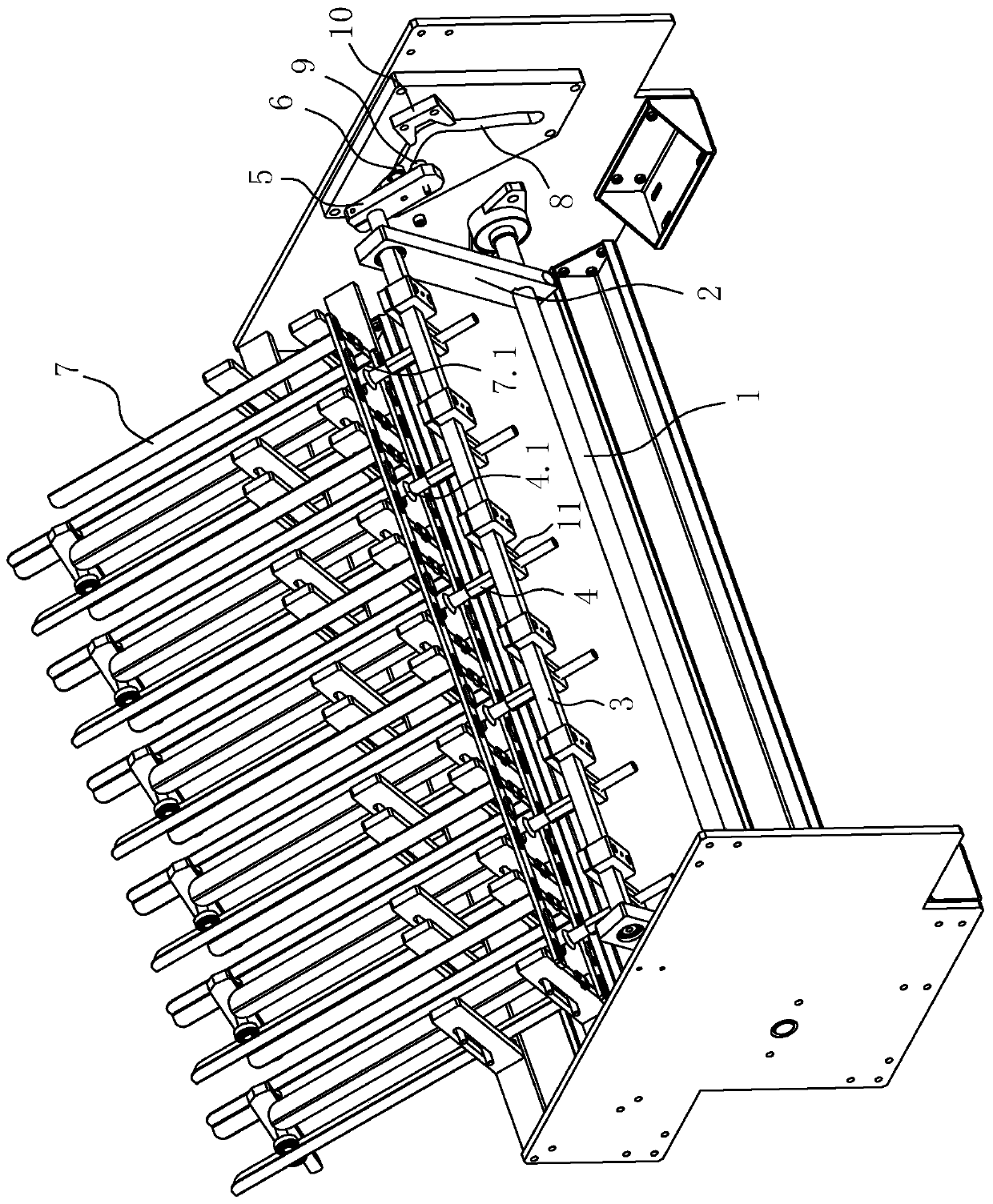

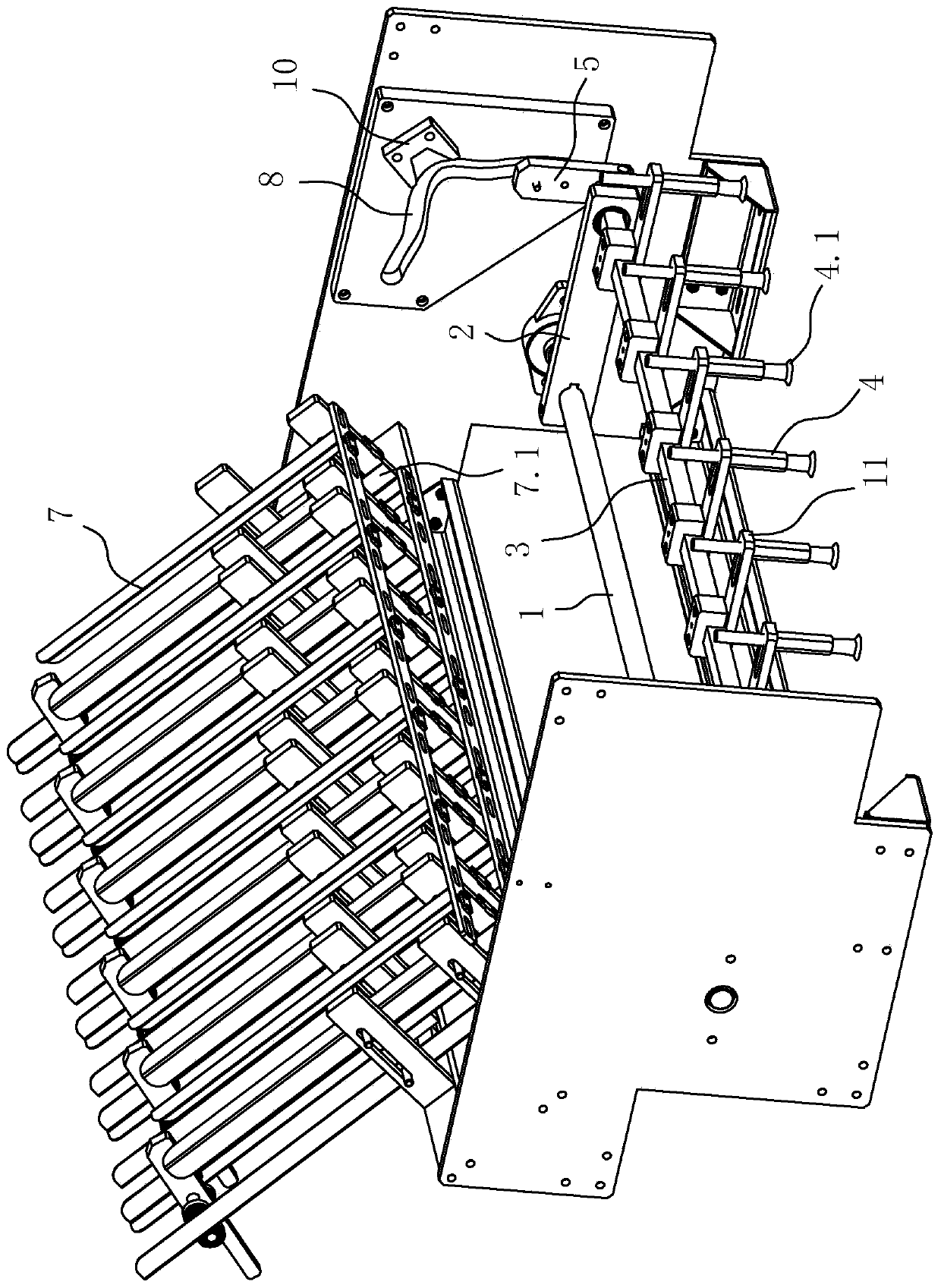

[0009] Such as Figure 1-2 As shown, a device for taking trays includes a revolving frame 2 that can be driven to rotate around a rotating shaft 1. A swinging shaft 3 that rotates parallel to the rotating shaft 1 is installed on the rotating frame 2. A suction cup manipulator is fixed on the swinging shaft 3. 4 and a crank 5, the crank 5 is equipped with a roller 6 that drives it to rotate, and the two sides above the rotating shaft 1 are respectively provided with a silo 7 for discharging the tray and a bellcrank-like slider for accommodating the movement of the roller 6. Rail 8, the corner of slide rail 8 is located at the center of the circle with rotating shaft 1, with the distance of swinging shaft 3 to rotating shaft 1 plus the distance of roller 6 to swinging shaft 3 as the radius, the crank 5 is at a certain distance from roller 6 A column pin 9 is installed at the extension end, and the outer side of the corner is fixed a stopper 10 that can block the column pin 9 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap