A method and equipment for transporting molten salt

A molten salt and equipment technology, applied in the field of molten salt transportation and equipment, can solve the problems of inability to realize small flow rate, precise and quantitative transportation of molten salt, and low heating efficiency, and achieve the effect of fast heating rate and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

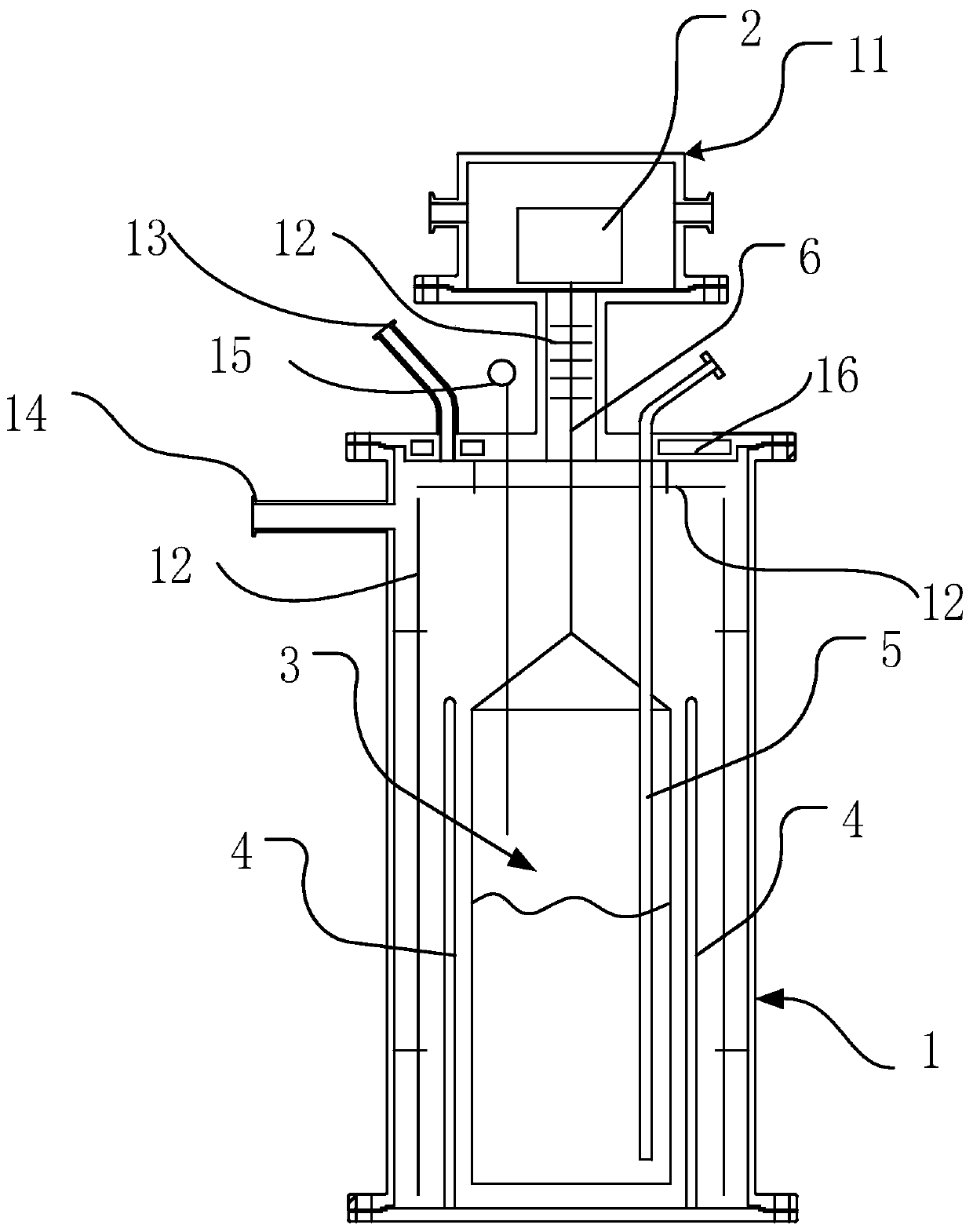

[0031] Such as figure 1 As shown, the present embodiment provides a device for heated storage and quantitative transportation of molten salt, which includes a sealed cavity 1, a weighing device 2, a molten salt bucket 3, a heating device 4, a melting Salt pipeline 5; the weighing equipment 2 and the molten salt bucket 3 are both arranged inside the sealed cavity 1, and the molten salt bucket 3 is connected to the molten salt bucket 3 through a suspension rod 6 3 above the weighing device 2 connected; the heating device 4 is located inside the sealed cavity 1 for heating the molten salt bucket 3; one end of the molten salt pipeline 5 extends to the The bottom of the molten salt bucket 3, the other end is located outside the molten salt transport equipment; the top of the sealed cavity is provided with a vacuum protection cover 11, and the weighing device 3 is located inside the vacuum protection cover 11 . A plurality of infrared reflective layers 12 are provided inside the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com