Slurry mixing and oil stirring device for sesame oil processing

A technology of stirring device and sesame oil, which is applied to mixers with rotary stirring devices, transportation and packaging, and accessories of mixers, etc. problems, to achieve high practicability and market prospects, good grinding and stirring effect, and the effect of improving oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

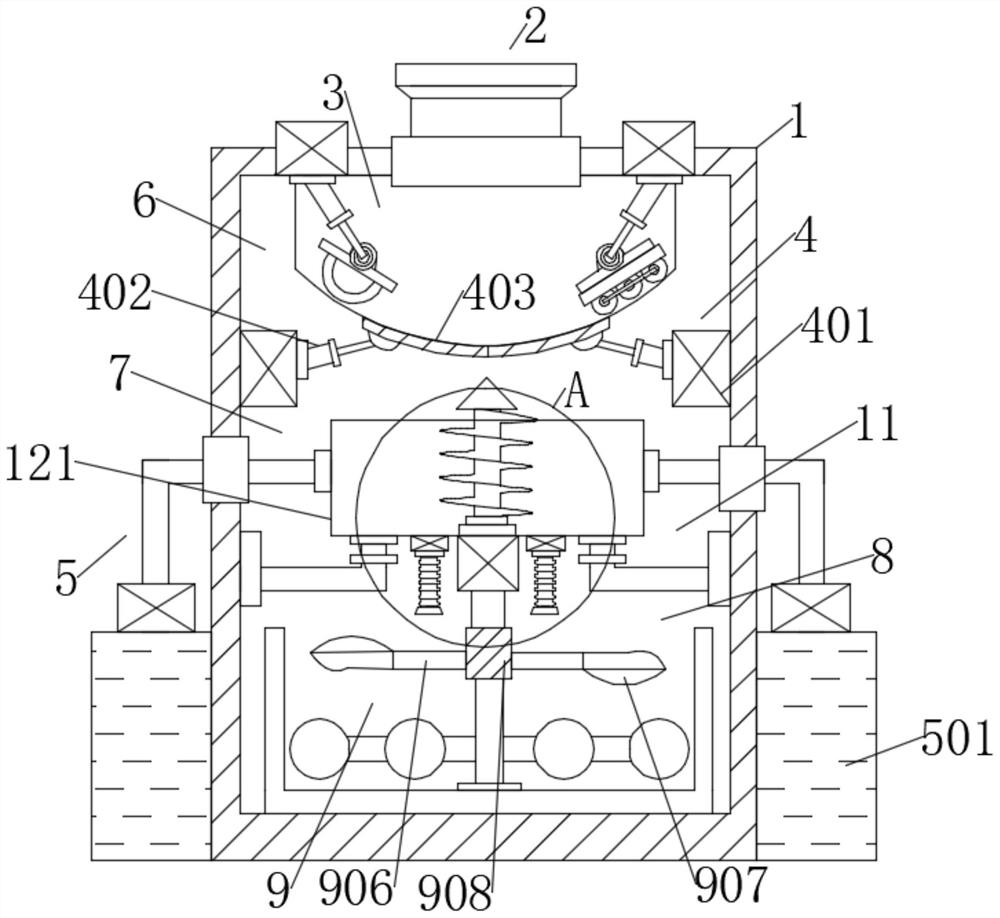

[0024] see Figure 1~4 , in an embodiment of the present invention, a blending and oiling device for sesame oil processing, comprising a casing 1, a grinding zone 6 above the inside of the casing 1, and a blending zone 7 below the grinding zone 6, in which The bottom of the slurry mixing area 7 is a slurry fixing area 8, a grinding mechanism 3 is installed inside the grinding area 6, a slurry mixing device 12 is installed inside the slurry mixing area 7, and a slurry mixing device 12 is installed above the inside of the shell 1. The bottom lifting device 4 used in conjunction with the grinding mechanism 3 is equipped with a fixed pulp stirring device 9 inside the fixed pulp area 8, and the fried and blown sesame seeds pass through the bottom lifting device after being ground in the grinding mechanism 3 4 Enter the bottom pulping and stirring device 12, after the pulping operation is completed, then enter the lower pulping and stirring device 9 for further processing, a water d...

Embodiment 2

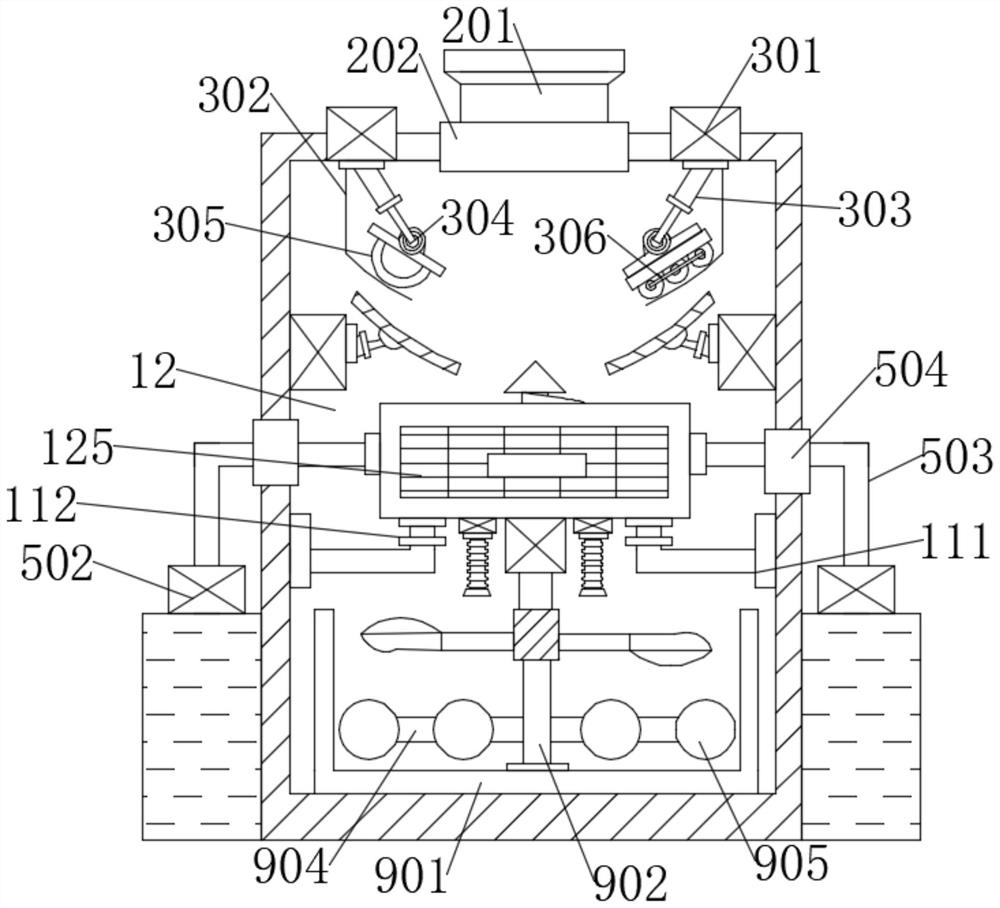

[0026] In this embodiment, a feeding assembly 2 is installed on the top of the housing 1, the feeding assembly 2 includes a feeding hopper 201 and a sealing ring 202, and the feeding hopper 201 is sealed and installed on the top of the housing 1 through the sealing ring 202; The grinding mechanism 3 includes two first motors 301, a grinding bin frame 302, two first telescopic sleeves 303, a main grinding roller 305 and an auxiliary grinding roller 306, and the two first motors 301 are respectively installed on the left and right sides of the top of the housing 1 On both sides, a connecting shaft frame 304 is installed at the bottom of the first telescopic sleeve 303 on the left and right sides, the main grinding roller 305 is electrically connected with the first motor 301 on the left side through the first telescopic sleeve 303, and the auxiliary grinding roller 306 passes through The first telescopic sleeve 303 is electrically connected to the first motor 301 on the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com