Powder feeding mechanism and operation method of functional gradient powder material

A powder material and functional gradient technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of difficulty in controlling the amount of powder feeding, difficulty in ensuring the accuracy of powder conveying, and easy blocking of the outlet, so as to meet the requirements of powder conveying accuracy. requirements, alleviate the phenomenon of powder clogging, and ensure the effect of safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

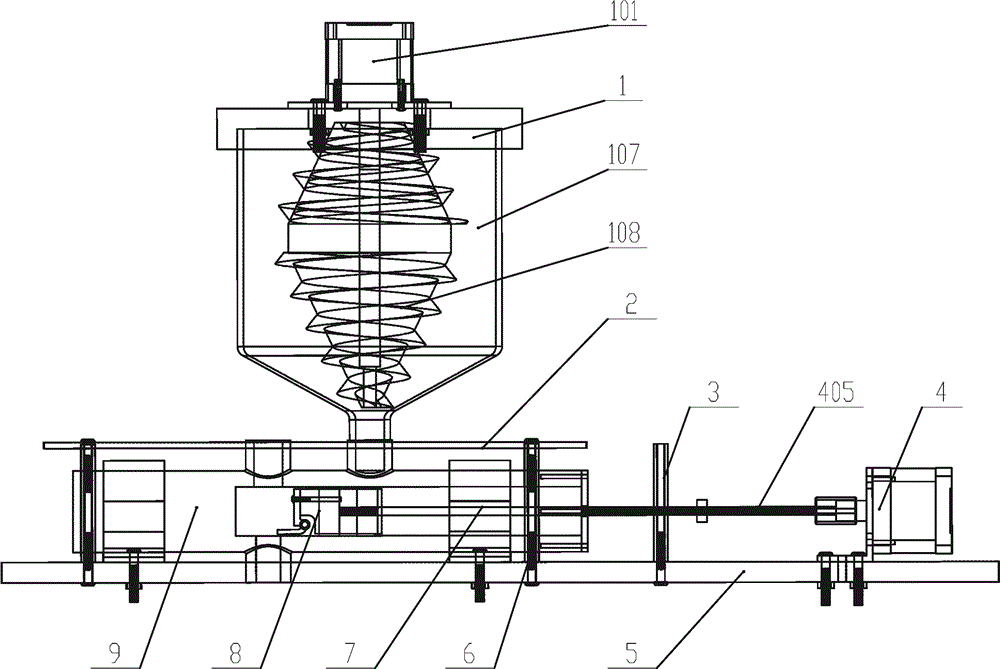

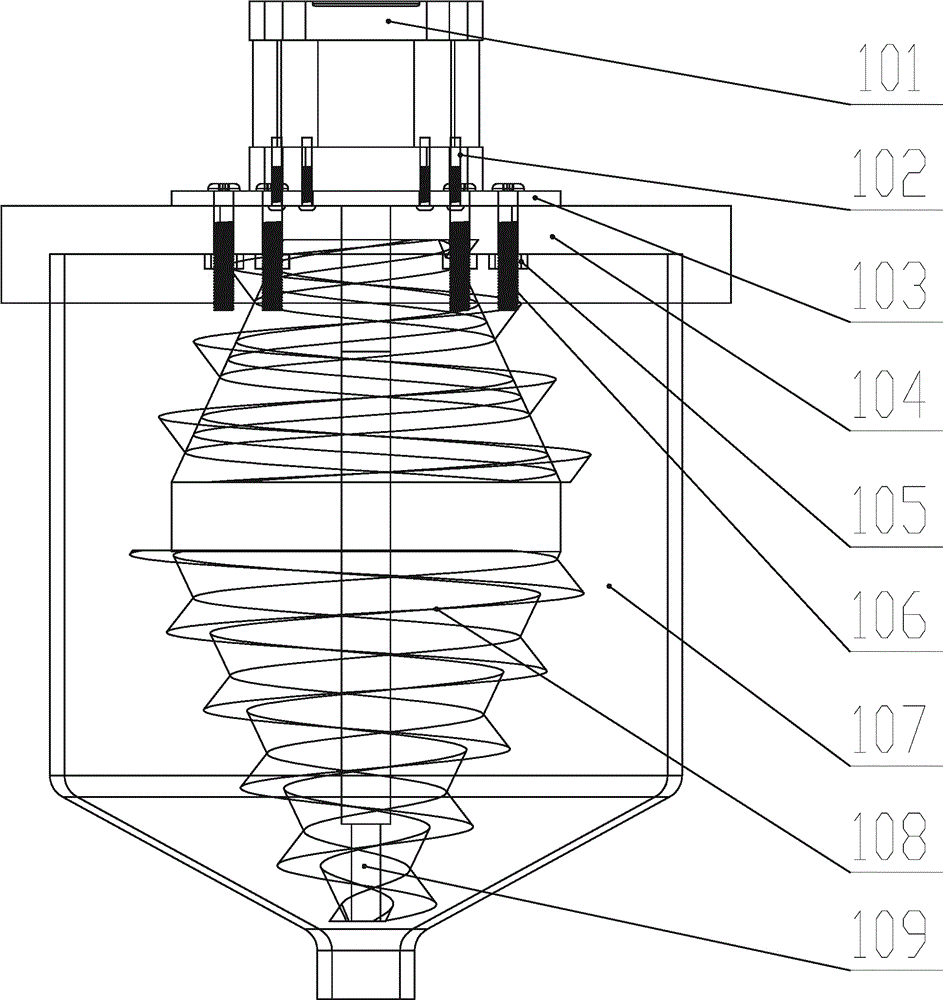

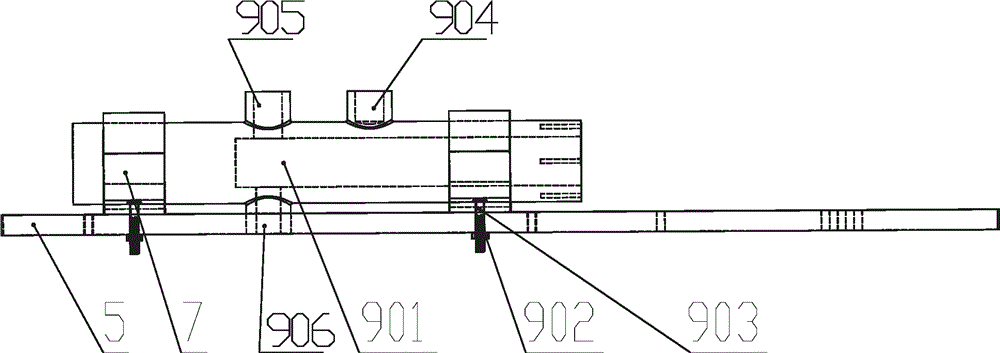

[0039] like figure 1 As shown, the powder feeding mechanism for functionally graded powder materials includes a mechanism bottom plate device 5, and the left side of the mechanism bottom plate device 5 is fixedly connected with two cylinder body fixing parts 7 by bolts, and the cylinder body body fixing parts 7 connect the cylinder body through interference fit. The component 9 is fixed on the mechanism bottom plate device 5, the middle part is fixedly connected with the left limit copper column 3, and the right side is fixedly connected with the transmission mechanism 4 through bolts, the transmission mechanism 4 is connected with the slider 8 in the cylinder through the threaded rod 405, and the cylinder body assembly 9. The upper part is connected with the upper support plate 2 through clearance fit. The cylinder assembly 9 is connected between the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com