Modified intensive aeration and vein type biofilter

A biological filter, an improved technology, applied in the direction of sustainable biological treatment, reflux water treatment, water/sludge/sewage treatment, etc., can solve the problem of unsatisfactory removal of organic matter, limited removal of nitrogen denitrification, lack of exhaustion Oxygen and anoxic environment and other problems, to achieve good denitrification and denitrification, excellent decarbonization, and improve the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (1)

[0039] Embodiment (1): municipal sewage treatment

[0040] A pilot plant of an improved intensive aeration and venous biofilter was set up in a municipal sewage treatment plant in Jiangxi. The material of the device is made of carbon steel for anticorrosion.

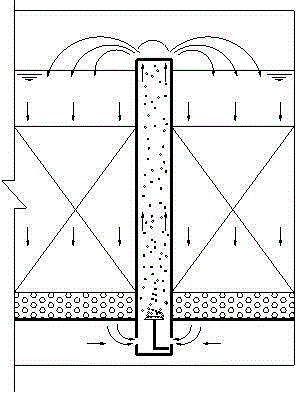

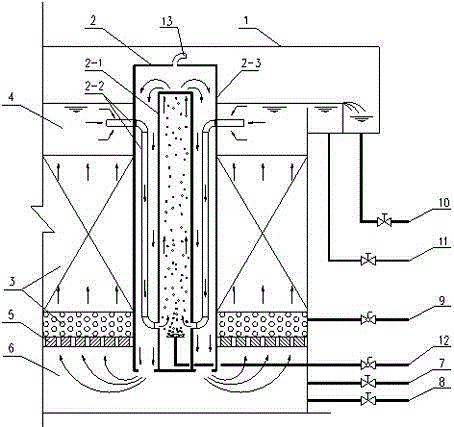

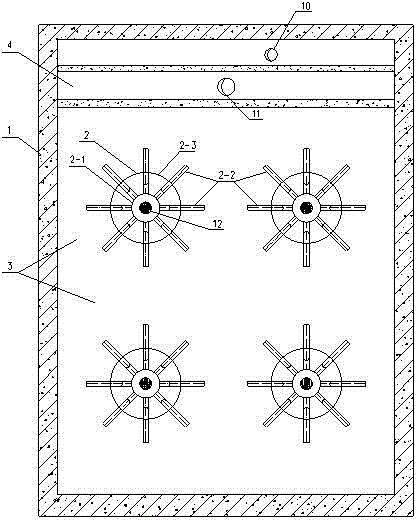

[0041] 1) The overall dimensions of the device are: L×W×H=1600mm×1600mm×2650mm, and the inner central area contains an intensive aeration and diversion circulation device;

[0042] 2) The size of the outer guide cylinder of the intensive aeration and diversion circulation device is: ?800mm×2650mm, the size of the inner guide cylinder is: ?300mm×2250mm, and the size of the suction pipe connecting the inner and outer guide cylinders is DN80mm , a total of 6 are evenly distributed along the circumference, the upper suction port of each one is 250mm beyond the outer guide tube, and the size of the vent pipe above the outer guide tube is DN80mm;

[0043] 3) The height of the water distribution area at the bottom of the devic...

Embodiment (2)

[0048] Example (2): Treatment of industrial high-concentration wastewater (coking plant ammonia distillation wastewater)

[0049] A pilot plant of an improved intensive aeration and venous biofilter was set up in the sewage treatment plant of a coking plant in Jiangxi. The main body of the flow circulation device is made of stainless steel SUS304.

[0050] 1) The overall dimensions of the device are: L×W×H=2000mm×3500mm×3750mm, and the inner central area contains 2 intensive aeration and diversion circulation devices;

[0051] 2) The size of the outer guide cylinder of the intensive aeration and diversion circulation device is: ?1100mm×3650mm, the size of the inner guide cylinder is: ?400mm×3250mm, and the size of the suction pipe connecting the inner and outer guide cylinders is DN100mm , a total of 8 are evenly distributed along the circumference, the water suction port on each one is 350mm beyond the outer guide tube, and the size of the vent pipe above the outer guide tub...

Embodiment (3)

[0058] Example (3): Advanced treatment of petrochemical wastewater

[0059] Set up an improved intensive aeration and venous biofilter pilot plant in the sewage treatment plant of a petrochemical company in Shandong, which is compatible with the traditional upward flow biological aeration filter of a local engineering company in Shandong and the one of a company in Beijing The downflow internal circulation biological aerated filter competes in the same field. in:

[0060] 1) The pilot plant of the improved intensive aeration and venous biofilter provided is the same device as that used in the above example (1), and the main material is carbon steel for anticorrosion. The overall dimensions are: L×W×H=1600mm×1600mm×2650mm, and the inner central area contains an intensive aeration and diversion circulation device, in which the total amount of biological filler is 2m3;

[0061] 2) The overall dimensions of the upflow biological aerated filter provided by an enterprise in Shandong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com