Micro animal attachment composite filler

A combined, animal-based technology, applied in the direction of biological sludge treatment, special compound water treatment, special treatment goals, etc., can solve the problems of limiting the application and development of sludge biological predation technology, the decline of predation ability, and the inability to grow stably. Improve the effect of sludge reduction, convenient transportation and carrying, and high efficiency of sludge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

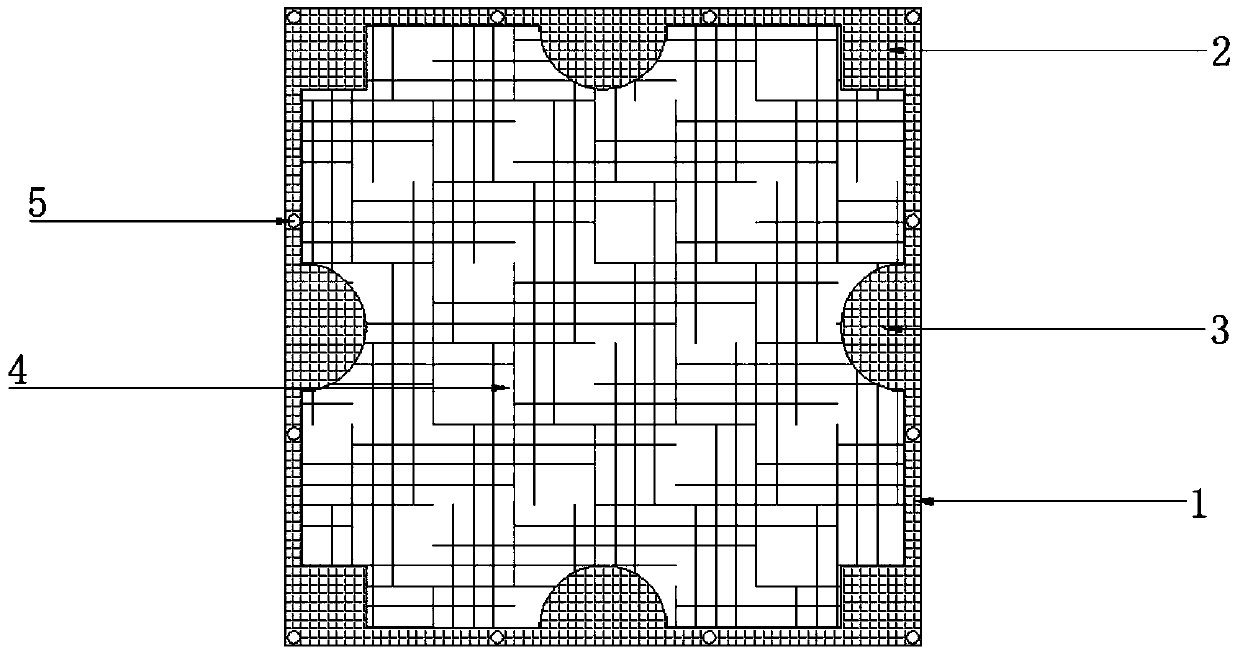

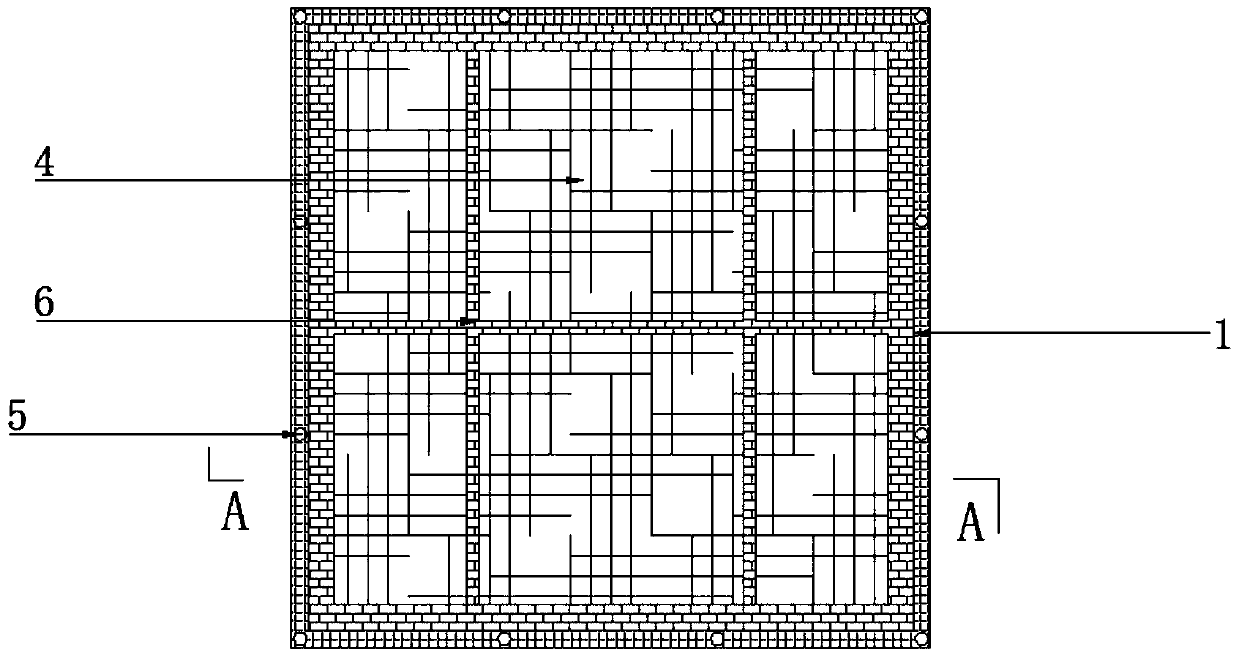

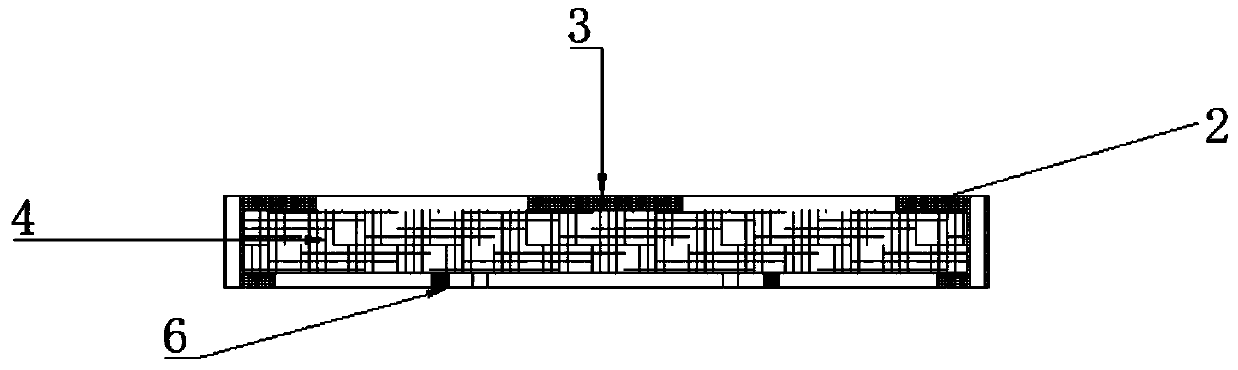

[0015] Specific implementation mode one: combine Figures 1 to 5 Describe the present embodiment, the new micro-animal attachment combined packing of the present embodiment, it consists of packing frame 1, square gland 2, semicircular gland 3, carrier 4, perforation eye 5, bottom bracket 6, connecting cable 7 and support column 8 composition;

[0016] Among them, the packing frame 1 is provided with a carrier 4, the square gland 2 is arranged at the four corners of the packing frame 1 to fix the carrier 4, the semicircular gland 3 is buckled in the middle of the carrier 4, and the perforation holes 5 are distributed on the packing frame 1. The bracket 6 is located at the bottom of the carrier 4, and supports the carrier 4 in a horizontal and vertical direction; the connecting cable 7 connects the carrier 4 and the bottom bracket (6) through the perforated hole 5; the supporting column 8 is set on the connecting cable 7; the carrier 4 is a place for attaching microscopic animal...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figures 1 to 5 This embodiment is described. The first difference between this embodiment and the specific embodiment is that the perforated holes 5 are distributed on the filler frame 1, and the number of holes is not limited. Other compositions and connection methods are the same as those in Embodiment 1.

[0018] The setting of the perforated holes 5 makes the upper and lower carriers staggered, which is beneficial to the upward transmission of oxygen at the bottom.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figures 1 to 5 Describe this embodiment, the difference between this embodiment and the specific embodiment is: the connecting cable 7 connects the upper carrier 4 and the bottom bracket 6 with the lower carrier 4 and the bottom bracket 6 through the perforated eye 5 arranged on the filler frame 1 Its staggered distribution, other composition and connection methods are the same as those in Embodiment 1.

[0020] Specific implementation mode four: combination Figures 1 to 5 This embodiment is described. The difference between this embodiment and the specific embodiment is that the support column 8 is sleeved on the connecting cable 7 to connect the gap between the upper carrier 4 and the bottom bracket 6 and the lower carrier 4 and the bottom bracket 6 . Other compositions and connection methods are the same as those in Embodiment 1.

[0021] Specific implementation mode five: combination Figures 1 to 5 This embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com