Dual-filler biological waste gas purifier

An exhaust gas purifier and double packing technology, applied in chemical instruments and methods, air quality improvement, dispersed particle separation, etc., can solve complex, easy-to-block operations and other problems, achieve strong impact load resistance, small footprint, The effect of a good distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

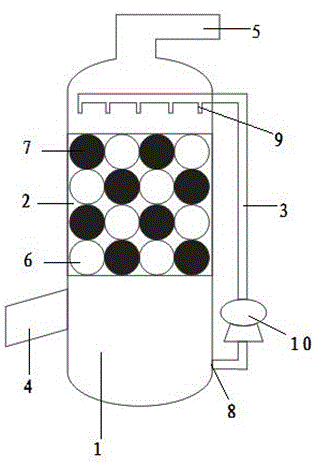

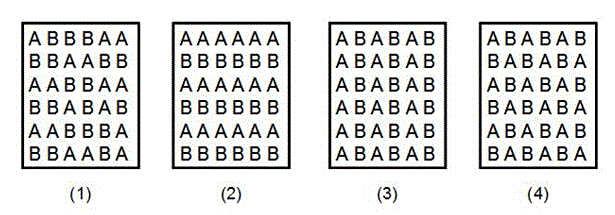

[0011] Combine the following figure 1 , to specifically illustrate the present invention, a dual-filler biological waste gas purifier includes a housing 1, a feeding chamber 2, a water circulation system 3, an air inlet 4 at the lower part of the housing 1 and an air outlet 5 at the upper part of the housing 1. The housing 1 is provided with a feed chamber 2 inside, and the feed chamber 2 is provided with a biofilm filler 6 coated with an antibacterial nanoparticle filler 7, and the biofilm filler 6 and a filler coated with an antibacterial nanoparticle filler 7 are mixed and filled in the In the feeding chamber 2 described above, a water circulation system 3 is provided on one side of the housing 1. The water circulation system 3 includes a water outlet 8, a water inlet 9, and a circulation pump 10. The water outlet 8 is installed in the housing 1 lower end, the water inlet 9 is installed on the upper end of the housing 1 and is located on the feeding chamber 2, a circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com