Aluminum electrolysis cell provided with continuous anode

A technology of anode electrolysis and aluminum electrolysis, applied in the field of electrolytic cells, can solve the problems of unfavorable improvement of anode current distribution, high quality requirements of special bonding paste, and excessive size of pre-baked anodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

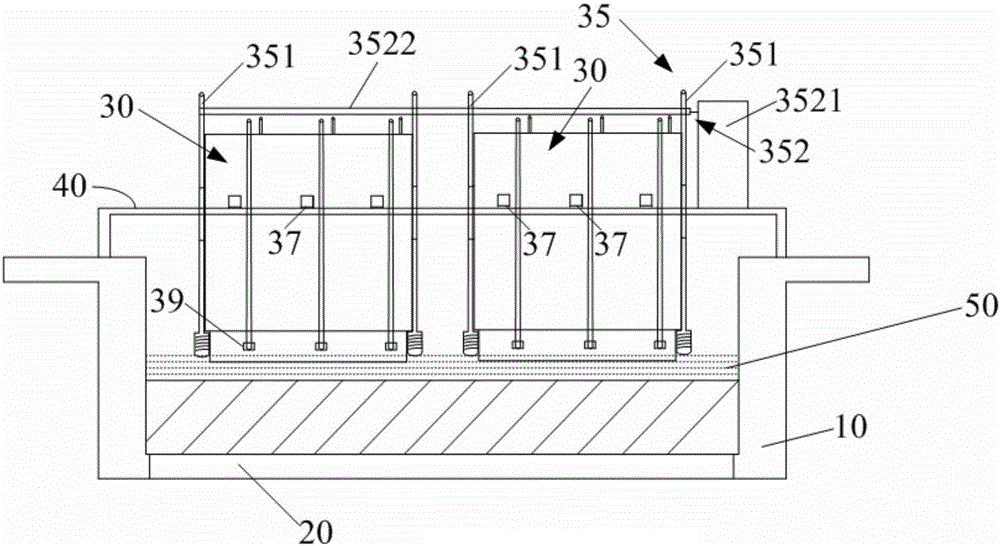

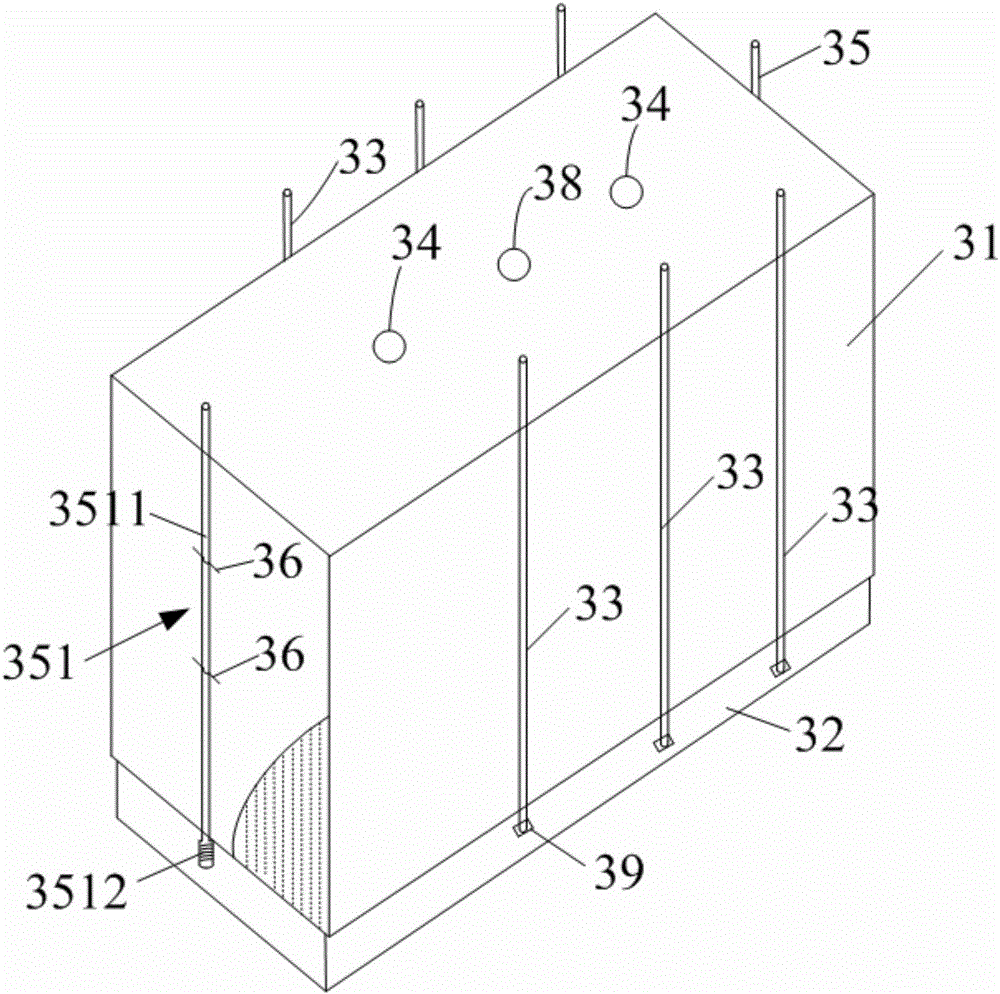

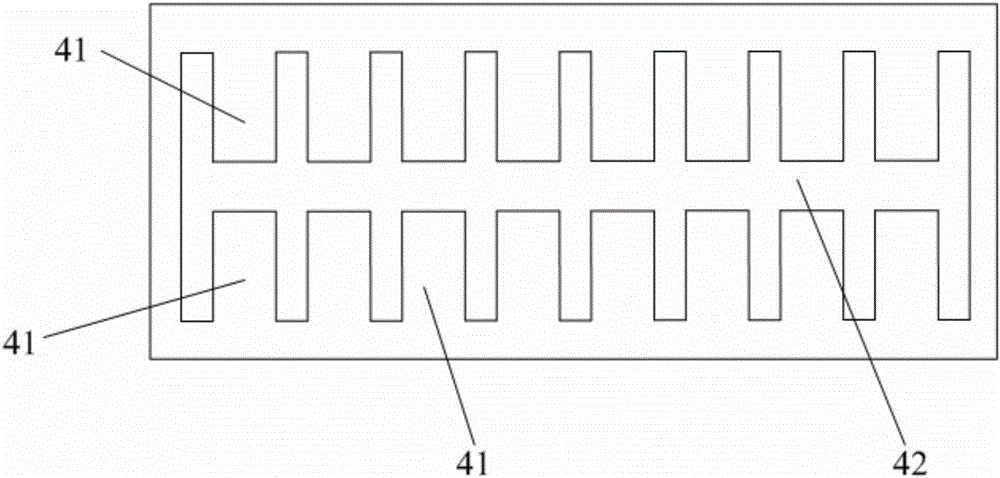

[0026] figure 1 It is a structural representation of a continuous anode electrolytic cell for aluminum electrolysis of the present invention, figure 2 It is a structural schematic diagram of a continuous anode assembly in an aluminum electrolysis continuous anode electrolytic cell of the present invention, image 3 It is a structural schematic diagram of a support plate in an aluminum electrolysis continuous anode electrolytic cell of the present invention. combine Figure 1 to Figure 3 As shown, the present invention provides a continuous anode electrolytic cell for aluminum electrolysis, including an electrolytic cell 10, a cathode 20 disposed at the bottom of the electrolytic cell 10, and a continuous anode assembly 30 disposed on the electrolytic cell 10, the continuous anode T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com