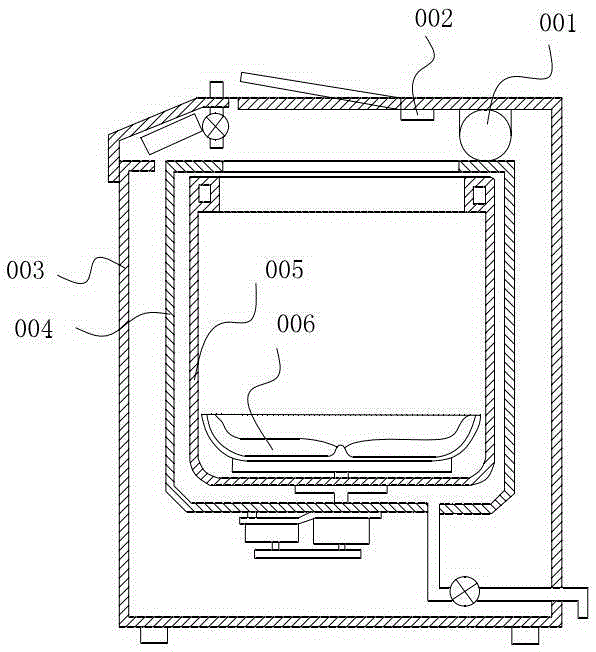

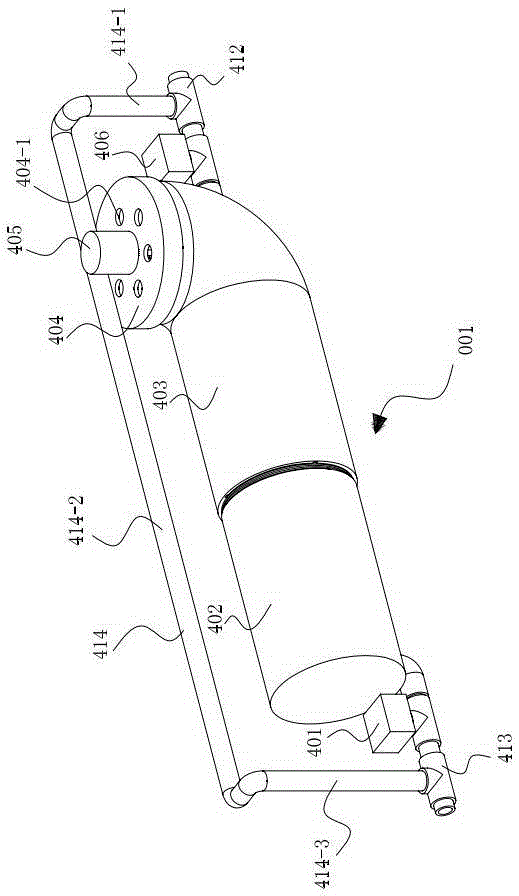

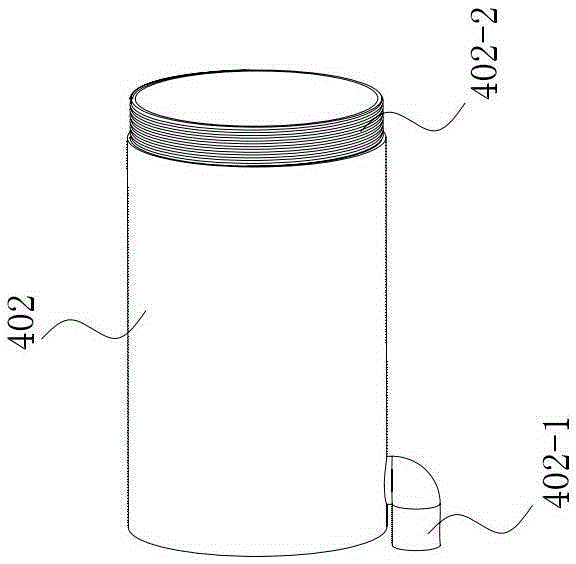

Impeller type washing machine with tubular detergent instant dissolver

A pulsator washing machine and washing powder technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of increased mechanical loss, increased vibration and noise, and difficulty in washing clothes, so as to increase disturbance, The effect of improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] The principle that the washing machine of the present invention can reduce the entanglement of the clothes during the washing process will be further described below in combination with the second preferred implementation mode of the pulsator 006 .

[0045] Looking at the pulsator 006 from above the pulsator 006, take the counterclockwise rotation direction as the forward direction. When the pulsator 006 rotates in the forward direction, under the agitation of the impeller, the washing water below the pulsator 006 is slapped to the surroundings, and moves upward through the diversion channel arranged inside the inner cylinder 005 of the washing machine, and is sprayed from the upper opening to the washing machine. The bottom of the inner cylinder 005, and part of the washing water above the pulsator 006 flows into the pulsator 006 through the through hole 6 on the pulsator plate 1, the water spray hole 8, and the gap between the periphery of the pulsator plate 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com