Gas extraction method for region reinforcement of gob-side entry retaining

A technology of gas extraction and empty road retention, which is applied in gas discharge, mining equipment, earth-moving drilling, etc., can solve the problems of difficulty in forming holes, weak stability, and inability to continue gas extraction through drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The method of the present invention based on the reinforced gas drainage in the gobside entry retaining area, the specific steps are as follows:

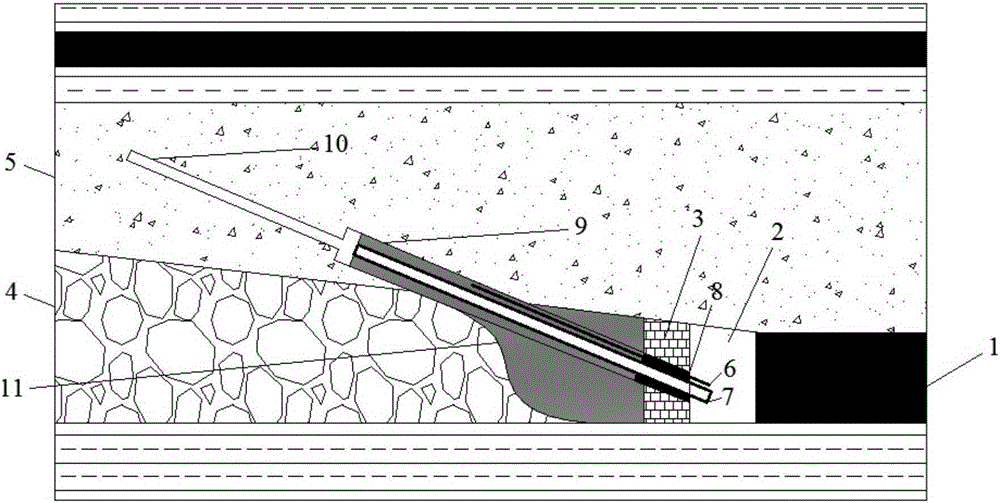

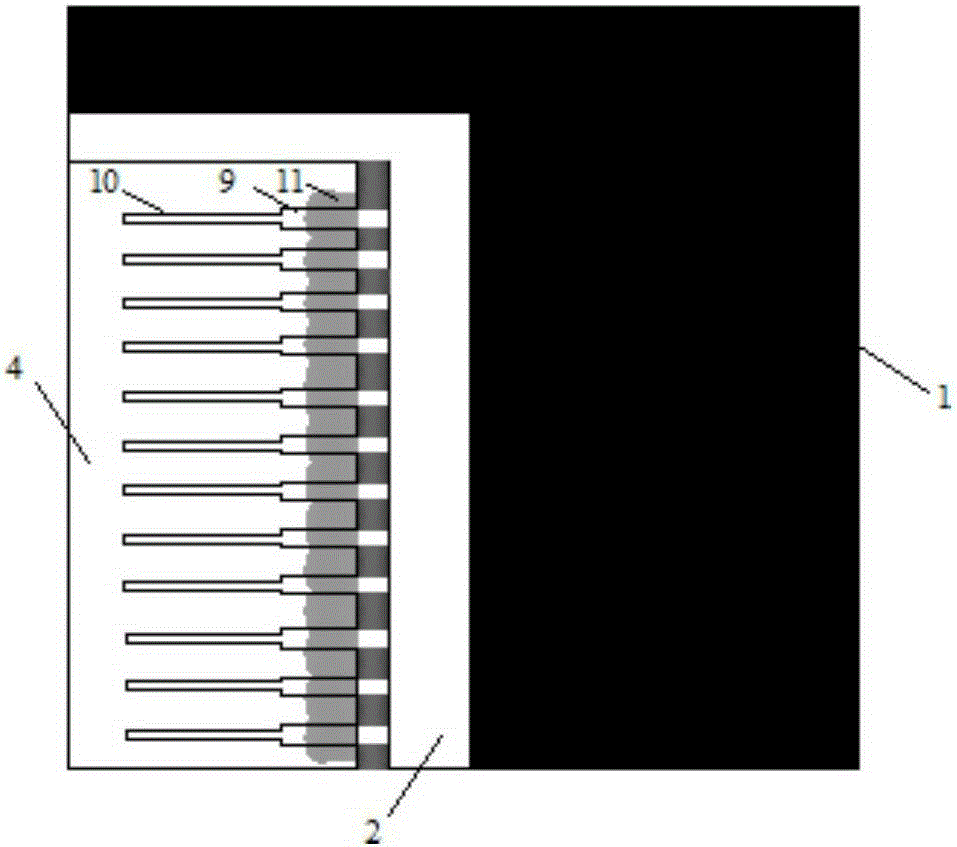

[0019] a. A gob-side entry 2 is formed between the coal body 1 and the filling wall 3, and a large borehole 9 is constructed on the side of the filling wall 3 of the gob-side entry 2 and passes through the collapse zone 4 toward the roof. The collapse zone 4 stops after entering the fissure zone 5 at a depth of 2 to 5 m; the diameter of the large boreholes 9 is 113 mm, and the distance between the opening positions of the large boreholes 9 is 5 to 10 m.

[0020] b. After drilling back, bind a grouting pipe 6 with an iron wire on the steel casing 7, and wrap polyurethane with a diameter of 94 mm on the steel casing 7 with a diameter of 94 mm and one end of the grouting pipe 6 for hole plugging with 8;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com