Rigid polyurethane insulation pipe containing polyurethane concentric device and manufacturing method

A technology for rigid polyurethane and thermal insulation pipes, applied in the direction of thermal insulation protection of pipelines, thermal insulation, pipeline protection, etc., can solve the problems of lowering the thermal insulation temperature and destroying the thermal insulation effect of polyurethane, and achieves the same thermal insulation effect and the same thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

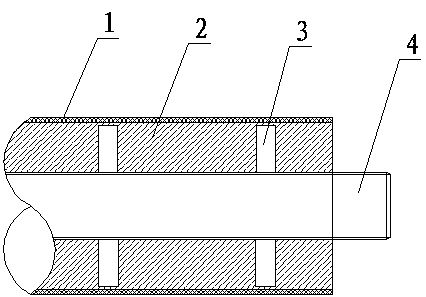

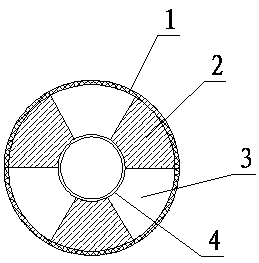

[0022] A rigid polyurethane thermal insulation pipeline containing a polyurethane concentric device, which consists of: a group of polyurethane concentric devices 3, a group of polyurethane concentric devices fixed to the outer wall of the working pipe 4 through polyurethane glue, and the polyurethane concentric device It is a regular block structure or a C-shaped ferrule structure fixed on the outer wall of the working tube. The polyurethane concentric device is covered with an outer protective tube 1, and the outer protective tube is connected with the working tube. The rigid polyurethane foaming agent 2 is perfused between the tube and the polyurethane concentric device.

Embodiment 2

[0024] According to the rigid polyurethane insulation pipeline containing polyurethane concentric devices described in Example 1, a group of polyurethane concentric devices are arranged in parallel on the outer wall of the working pipe, and the polyurethane concentric devices are placed in the working tube. The pipes are evenly distributed in the circumferential direction, and the polyurethane concentric device is made of high-density rigid polyurethane plastic foam.

Embodiment 3

[0026] A method for manufacturing a rigid polyurethane insulation pipe containing a polyurethane concentric device, the method comprising the steps of:

[0027] The first is to use high-density rigid polyurethane foam foaming technology to produce high-density rigid polyurethane foam with the same parameters as the designed thermal insulation pipe, and then use high-density rigid polyurethane foam to produce concentric pipes that match the design pipe model. The supporter, that is, the polyurethane concentric device, the polyurethane concentric device is made into a block structure, and is bonded on the outer wall of the working tube through polyurethane glue, and the polyurethane concentric device is made into a C-shaped ferrule, which can be directly stuck on the On the outer wall of the working pipe;

[0028] Using casing technology and pouring method to foam polyurethane plastic foam, jacket the foaming mold at both ends of the outer protective tube, and inject a rigid pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com