Gas inflow method for gas water heater and gas water heater

A gas water heater and air inlet technology, which is applied in the combustion method, burner, fluid heater, etc., can solve the problems of noise pollution, unstable air flow at the inlet air flow rate, and high working noise, and achieves the solution to the problem of high combustion noise, The effect of avoiding combustion oscillation and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

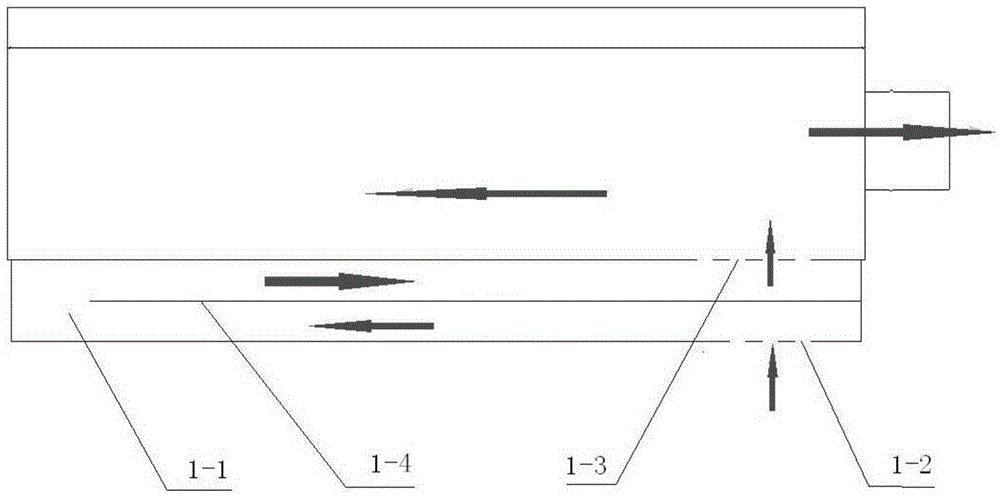

[0026] like figure 1 As shown, a gas water heater air intake method is characterized in that an air intake channel 1-1 is added to the air inlet of a strong pumping or strong drum type gas water heater, and the air intake channel 1-1 is used to prevent the internal noise of the gas water heater Spread out to reduce the use noise of the gas water heater from the perspective of noise transmission.

[0027] Specifically, preventing the noise inside the gas water heater from spreading out is achieved by staggering the air inlet 1-2 of the air intake channel 1-1 from the air inlet 1-3 of the gas water heater. In this embodiment, the preferred method of staggering is: a baffle plate 1-4 is set between the air inlet 1-2 of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com