Simulation multi-gap assembled medium tunnel seepage test method

A testing method, multi-void technology, applied in the direction of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of groundwater dynamic change law that has not been tried to study water inrush over time, and does not consider the influence of tunnel construction , unable to achieve dynamic research and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

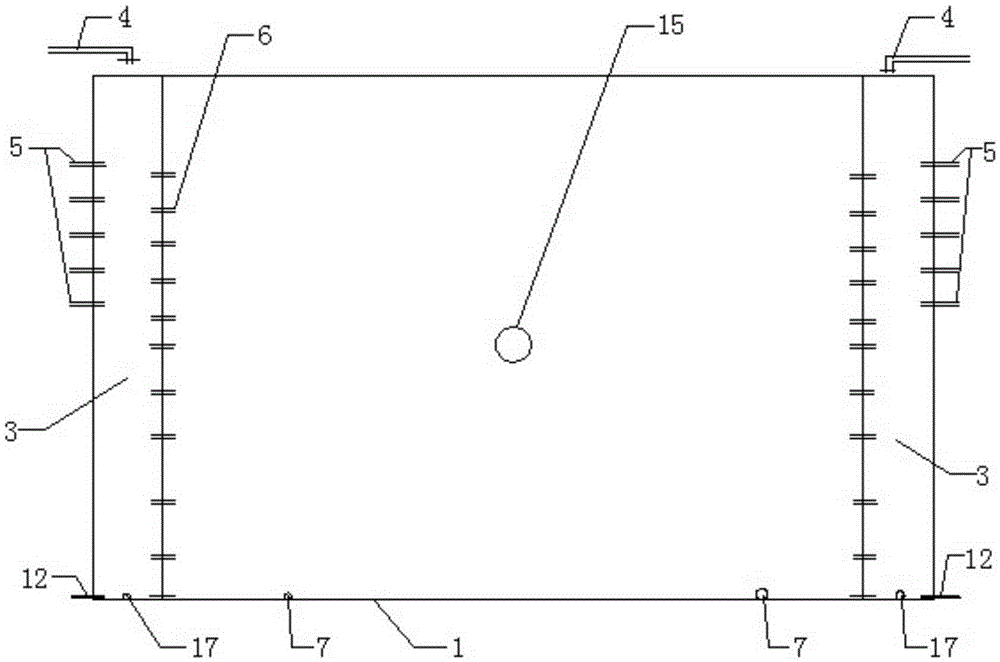

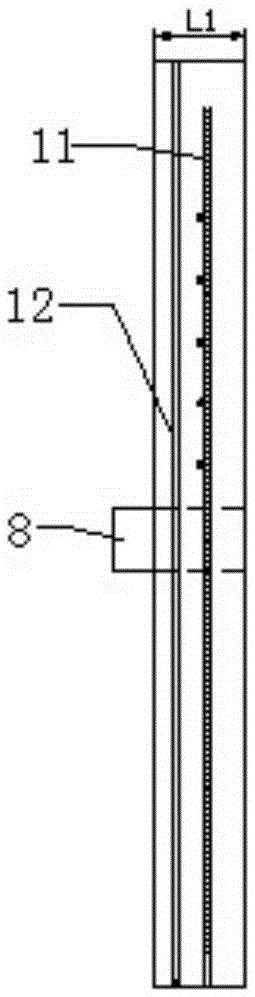

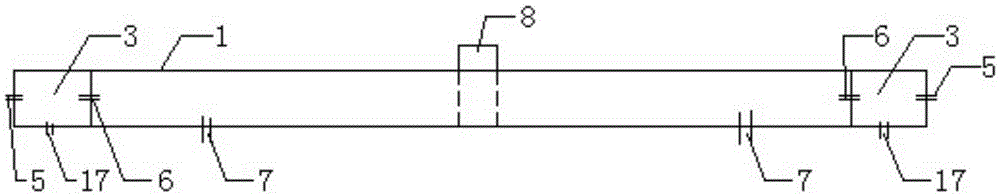

[0068] Such as Figure 1 to Figure 13 As shown, taking the main fracture angle of 30° in the excavation of a railway tunnel section as an example, the test method process for simulating the seepage of multi-void composite medium tunnels is described in detail.

[0069] The boundary of the tunnel model adopts a scale of 1:300. Taking the tunnel axis as the center, go left and right 300m, down 200m, buried depth 250m, total 45m front and back, the model size is length×width×height=2.0m×1.5m×0.15m. The tunnel is a double-line tunnel, generalized to a single-line tunnel, with a diameter of 30m and a model size of 10cm. Except for a side and top surface perpendicular to the tunnel axis, the remaining model boundary interfaces are made of concrete layers. The water tank 3 and the water inlet of the water tank are arranged on both sides of the model boundary 1, and the corresponding overflow port 5 and the water inlet pipe 6 are arranged. The filling medium in the multi-void combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com