Touch panel and touch display device

A technology of touch display device and touch panel, which is applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc. It can solve the problem of thermal deformation of ink and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

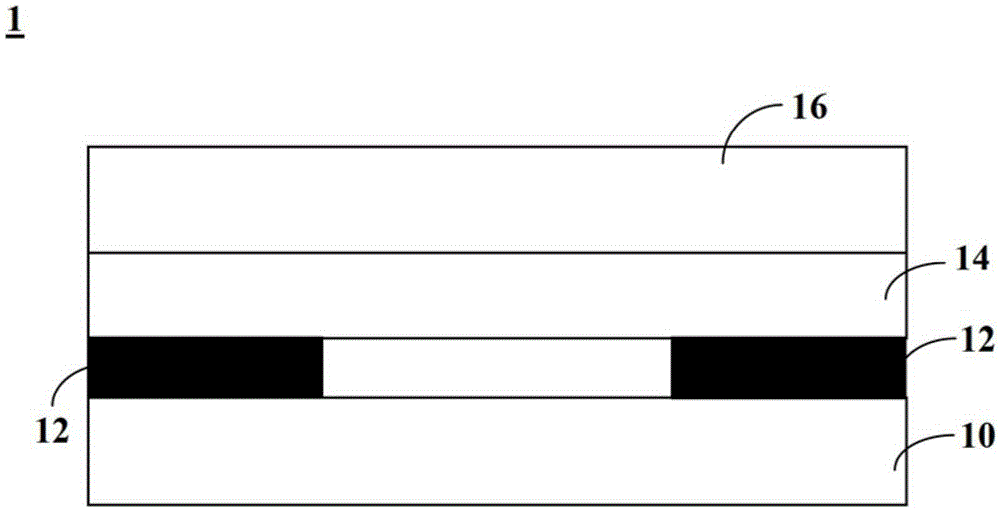

[0032] figure 1 A schematic structural diagram of an existing touch panel 1 is shown. The touch panel 1 includes a protective cover 10 , a first ink layer 12 , an optical adhesive layer 14 and a touch sensing layer 16 . The optical adhesive layer 14 is disposed between the protective cover 10 and the touch sensing layer 16 , and the first ink layer 12 is disposed around the protective cover 10 for shielding the non-sensing area. After bonding the protective cover 10 and the touch sensing layer 16 with the optical adhesive layer 14 , it is necessary to use a curing light source (such as ultraviolet light) to dry and cure the optical adhesive. When the first ink layer is a black or dark ink layer with a high absorption rate, the first ink layer 12 will absorb the heat of the curing light source and deform, resulting in the protective cover 16 and touch The sensing layer 16 is also deformed accordingly.

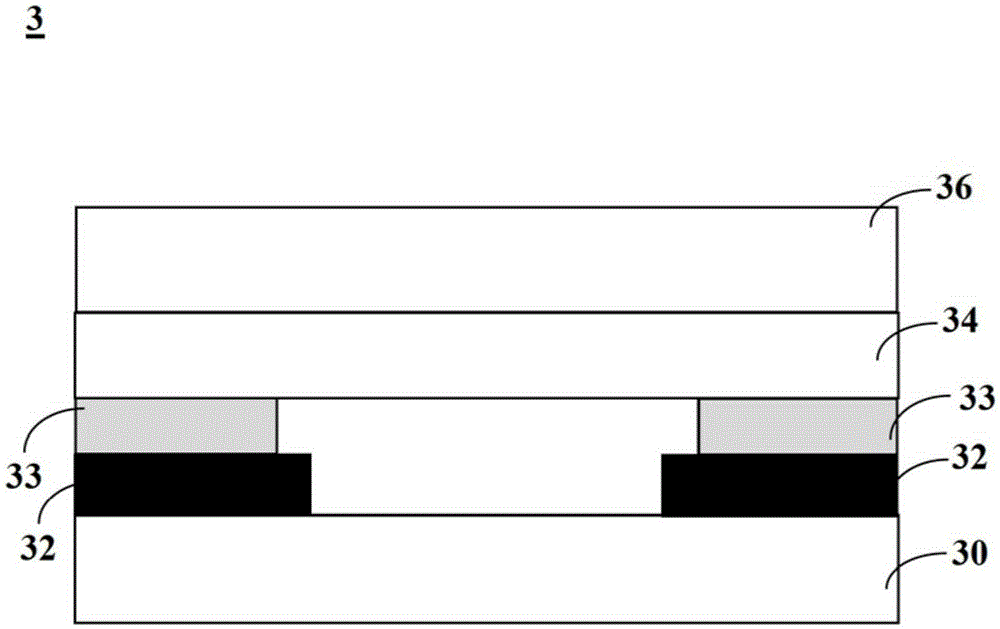

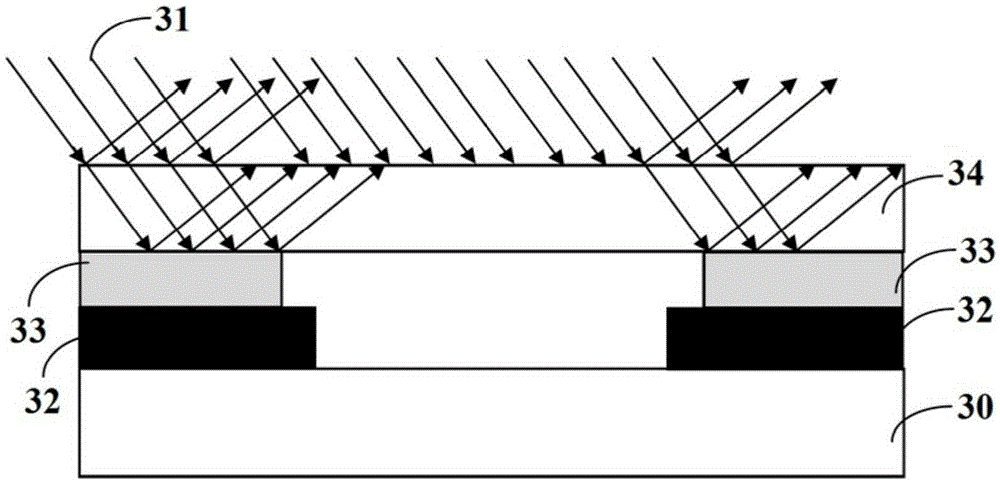

[0033] figure 2 A schematic structural diagram of the touch panel 3 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com