A 10kv oil-immersed transformer water cooling device

A technology for oil-immersed transformers and water-cooling devices, which is used in transformer/inductor cooling, mechanical equipment, pipes, etc., can solve the problem of increasing the weight of 10kV oil-immersed transformer core, electromagnetic wire, and increasing the no-load of 10kV oil-immersed transformer. Loss, waste of iron core, wire, transformer oil making materials, etc., to reduce temperature rise, prevent no-load loss, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

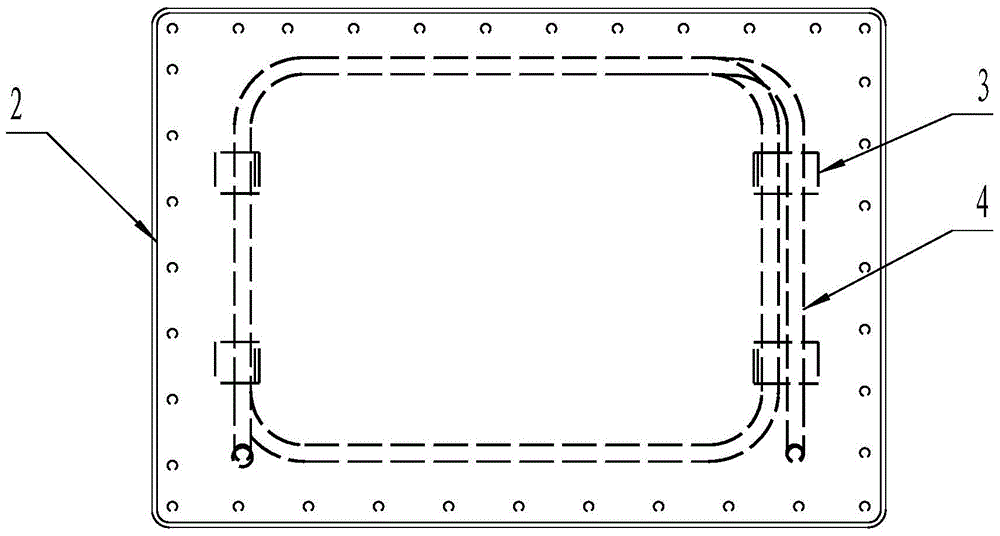

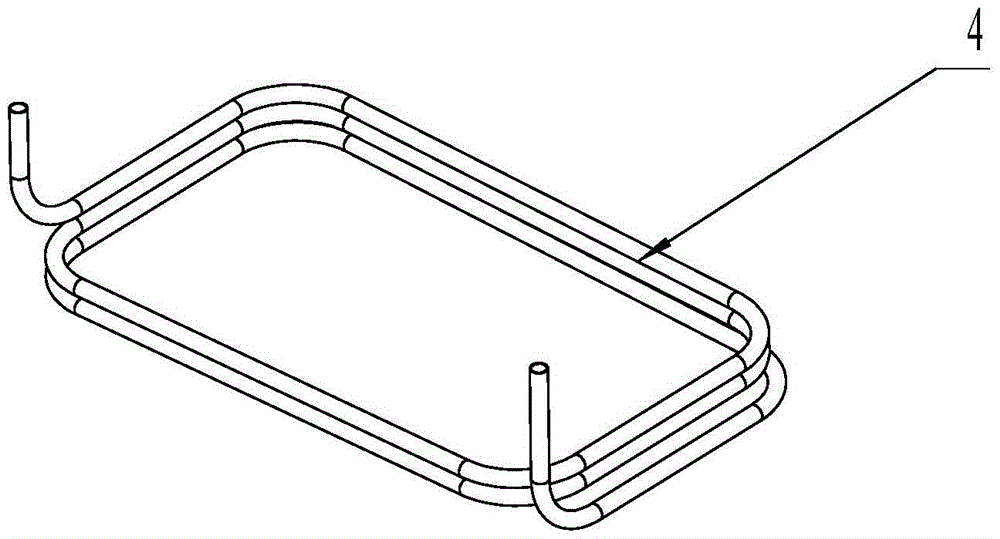

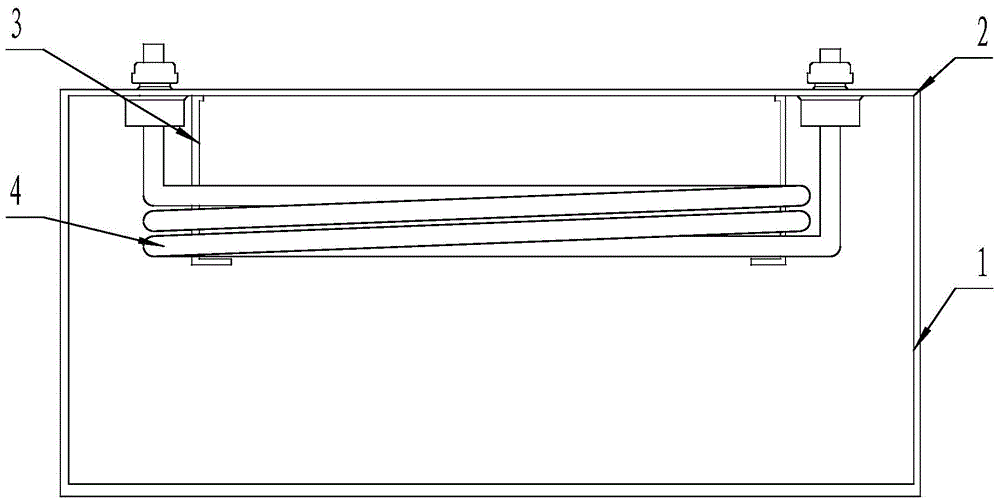

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a 10kV oil-immersed transformer water cooling device includes a transformer open oil tank 1 and an oil tank cover 2 that covers the transformer open oil tank 1. It is characterized in that: the bottom surface of the oil tank cover 2 is equipped with a The water cooling device for the temperature rise of the oil-immersed transformer; the water cooling device for reducing the temperature rise of the 10kV oil-immersed transformer includes a bent and wound seamless stainless steel pipe 4 and four L-shaped fixing plates 3, the L-shaped fixing plate 3 With a longer part and a shorter part, the bent and wound seamless stainless steel pipe 4 has a rectangular planar part and two end parts perpendicular to the planar part, and the four L-shaped fixing plates 3 is fixed on the bottom surface of the fuel tank cover 2 sequentially in a rectangular shape, the shorter part of the L-shaped fixing plate 3 is parallel to t...

Embodiment 2

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a 10kV oil-immersed transformer water cooling device includes a transformer open oil tank 1 and an oil tank cover 2 that covers the transformer open oil tank 1. It is characterized in that: the bottom surface of the oil tank cover 2 is equipped with a The water cooling device for the temperature rise of the oil-immersed transformer; the water cooling device for reducing the temperature rise of the 10kV oil-immersed transformer includes a bent and wound seamless stainless steel pipe 4 and six L-shaped fixing plates 3, the L-shaped fixing plates 3 With a longer part and a shorter part, the bent and wound seamless stainless steel pipe 4 has a rectangular planar part and two end parts perpendicular to the planar part, and the six L-shaped fixing plates 3 is fixed on the bottom surface of the fuel tank cover 2 sequentially in a rectangular shape, the shorter part of the L-shaped fixing plate 3 is parallel to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com