A kind of solar cell with ag transparent film and its preparation method

A solar cell and transparent thin film technology, applied in the field of solar cells, can solve the problems of increased lateral resistance and electrode resistance, increased solar cell series resistance, and decreased current collection capacity, achieving the goals of lower lateral resistance, low cost, and improved collection capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

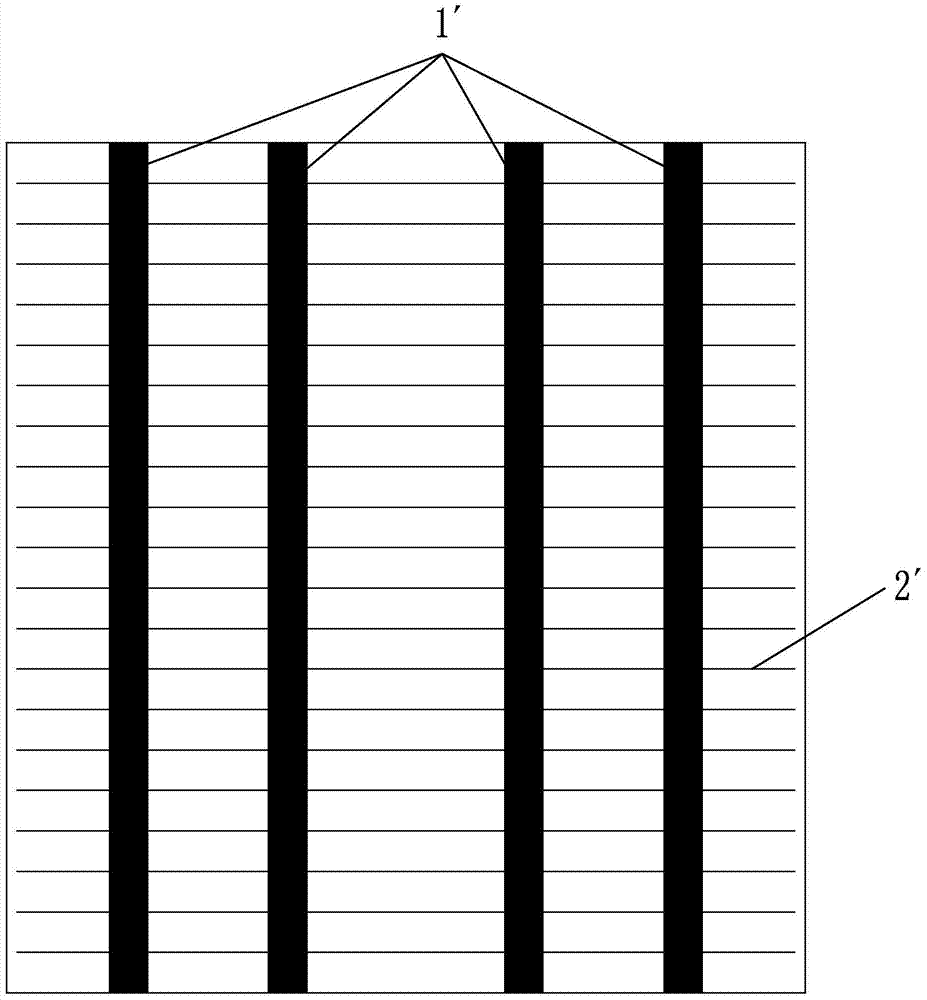

[0029] figure 1 It is a schematic diagram of the front electrode structure of a solar cell in the prior art. The front electrode of a solar cell is composed of a main grid line 1' and a sub-grid line 2'. The main grid line 1' and the sub-grid line 2' are perpendicular to each other. Parallel and evenly distributed, the auxiliary grid lines 2' are parallel to each other and evenly distributed, the main grid line 1' and the auxiliary grid line 2' are formed on the silicon wafer through the screen printing technology by passing the metal conductive paste through the screen mesh The electrode pattern is then sintered at high temperature to form electrodes in close ohmic contact. Due to the shading effect, the area of the front electrode is required to be as small a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com