Automatic formed-nail nailing machine for square power battery and work flow thereof

A power battery, square technology, applied in the direction of battery assembly, secondary battery manufacturing, battery pack parts, etc., can solve the problems of unreliability, battery scrapping, easy to stick electrolyte, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

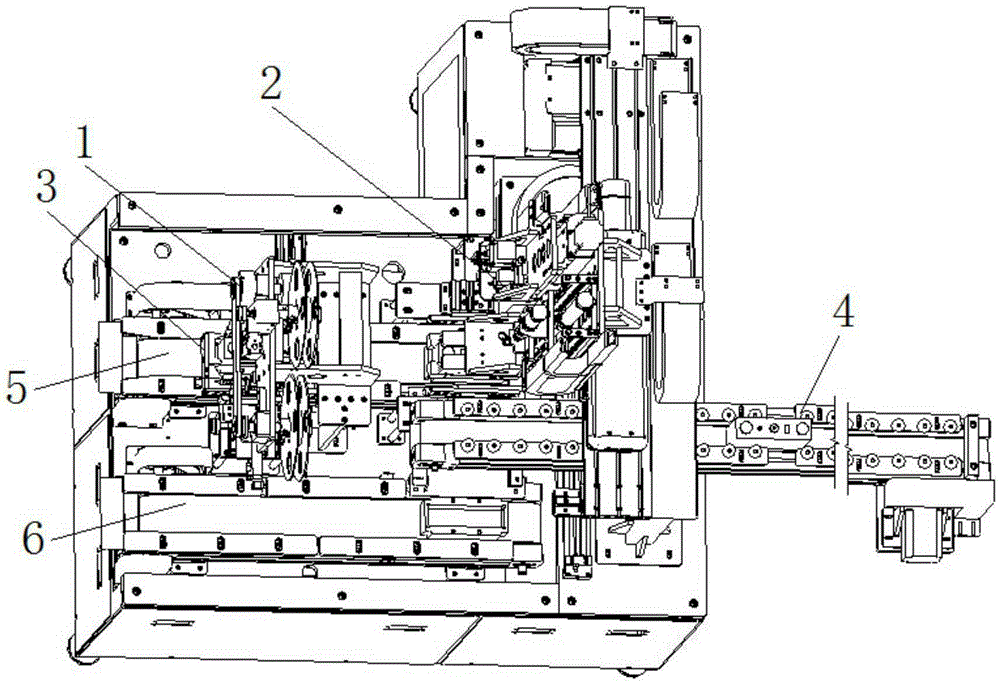

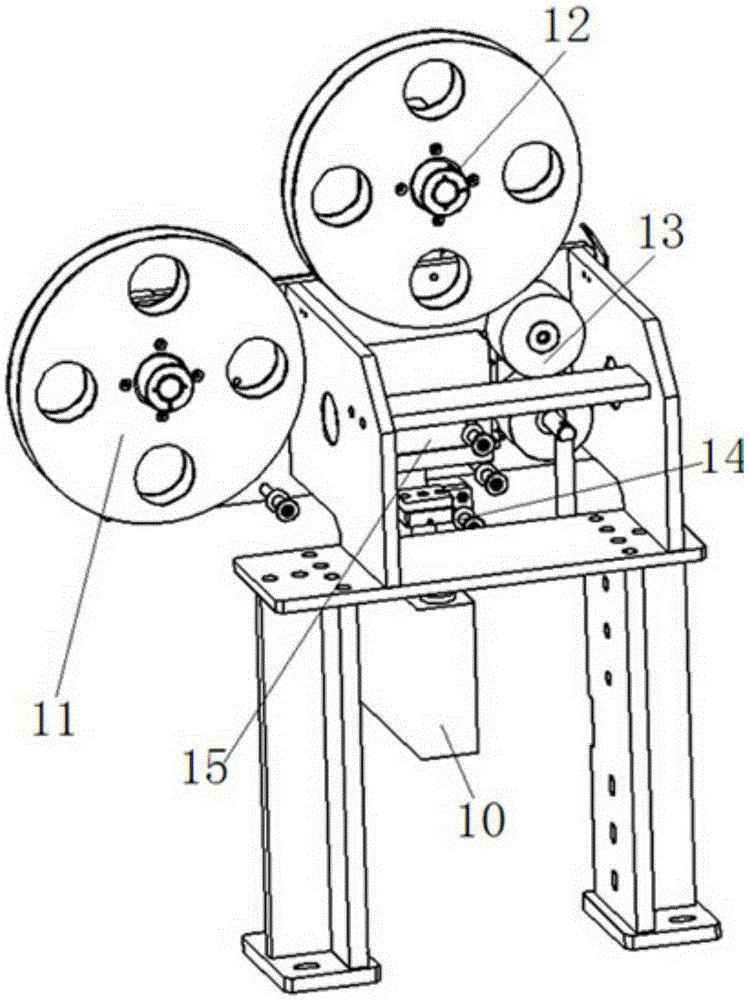

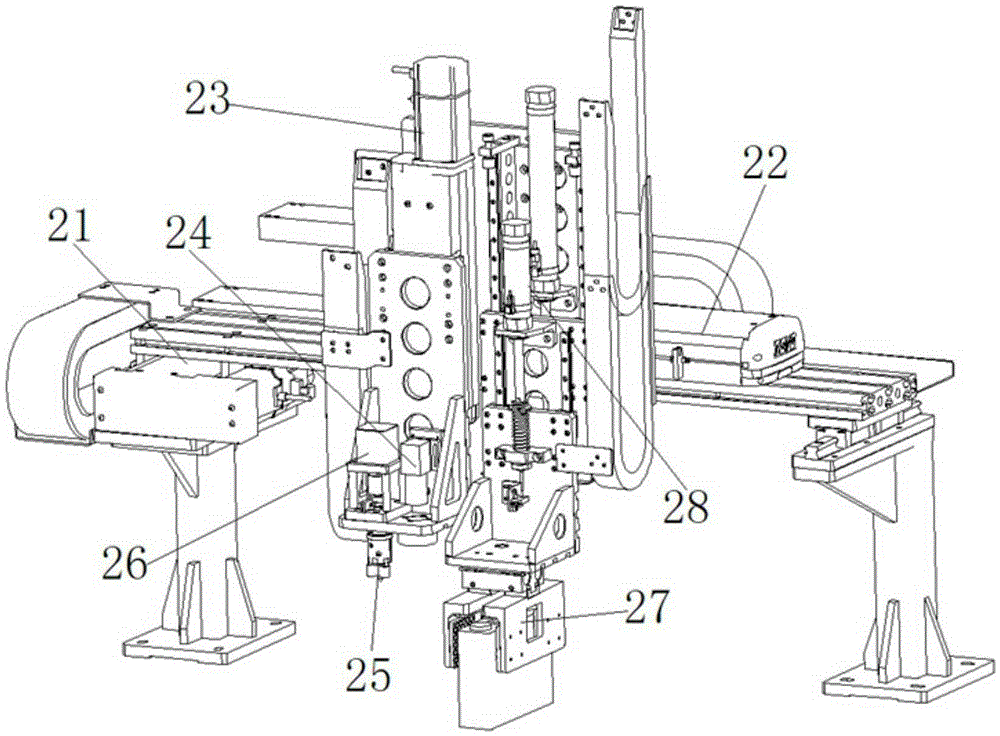

[0038] Such as Figure 1~6As shown, it shows a specific embodiment of the present invention; as shown in the figure, the square power battery automatic chemical nailing machine disclosed by the present invention is used for nailing the liquid injection port of the square power battery into a nail; The power battery includes a battery body 10 with a liquid injection port on the upper end; it includes a frame; A finishing and positioning component 3; the cleaning component 1 for cleaning the liquid injection port of the battery body is arranged above the finishing and positioning component; the position above the feeding pull belt behind the cleaning component is set for nailing the forming nail into the battery The nailing assembly 2 of the liquid injection port of the body; the side of the nailing assembly is provided with a transfer cable assembly 4 for transferring the nailed battery body to the outside of the frame;

[0039] As shown in the figure, the nailing assembly inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com