Composite used sand regenerator

A recycling machine and composite technology, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., can solve the problems of small application range and unsatisfactory regeneration effect, and achieve good rubbing effect. , Increase the probability of rubbing, improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

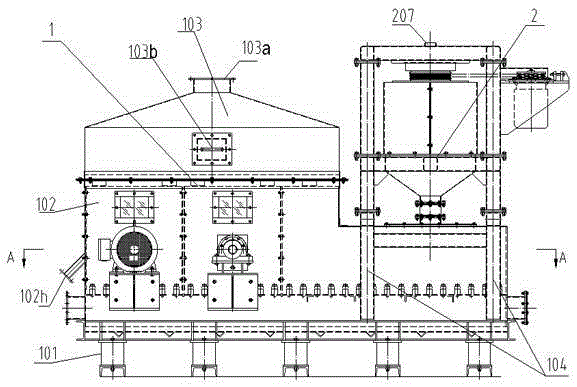

[0027] As shown in the figure, a composite old sand reclaimer includes a powerful ash remover 1 and a scrubbing reclaimer 2 .

[0028] Powerful ash removal machine 1 is provided with a frame 101, is provided with a sand box 102 on the frame 101, is provided with the first dividing plate 109 and the second dividing plate 110 at intervals in the sand box, the first dividing plate 109 and the second dividing plate The two partitions 110 divide the sand box into a left chamber 102a, a middle chamber 102b and a right chamber 102c.

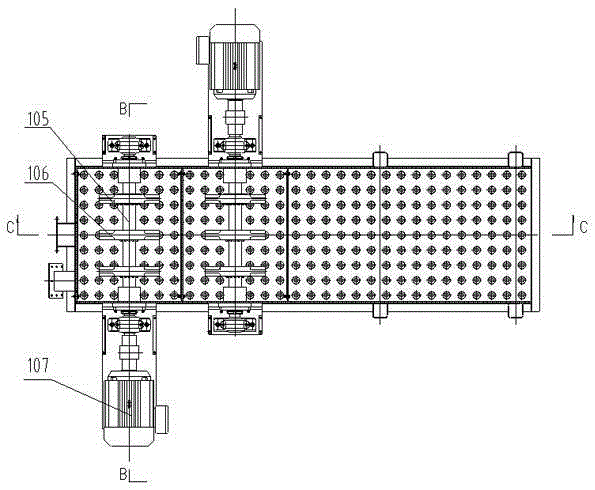

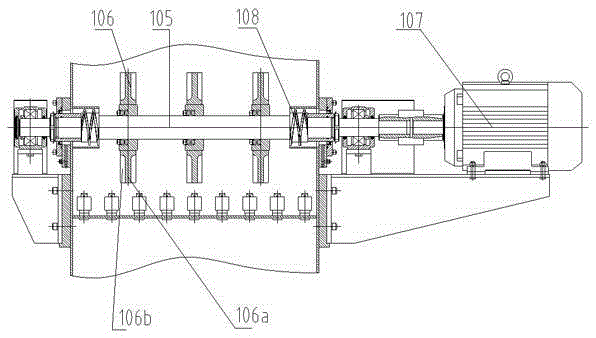

[0029] A rotating shaft 105 is arranged horizontally in the left chamber 102a and the middle chamber 102b respectively, the two rotating shafts are arranged parallel to the first partition 109, and the two ends of the rotating shaft pass through the sand box 102 and are rotatably arranged on the frame 101 or on the outer wall of the sand box.

[0030] In this embodiment, both ends of each rotating shaft 105 are respectively supported on the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com