Casting ladle capable of being heated

A ladle and ladle spout technology, applied in metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of increasing production costs, increasing duplication of labor, and dropping the temperature of molten aluminum, so as to avoid re-melting, The effect of reducing production costs and saving repetitive processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

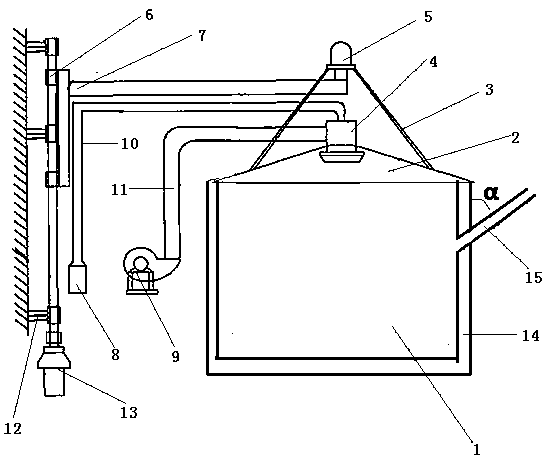

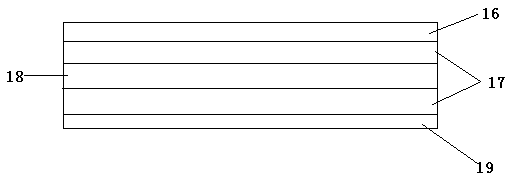

[0012] Example: such as figure 1 As shown, a heatable ladle includes a ladle 1 and a ladle cover 2 covering the ladle 1, a burner 4 is arranged on the ladle cover 2, and a vent pipe 10 and a vent pipe are connected in the burner 4 11. The ventilation pipe 10 is connected with the gas bottle 8 to provide combustible gas for the burner 4. The ventilation pipe 11 is connected with the blower 9 to provide the air required for combustion of the burner 4. It also includes a screw rod fixedly connected to the wall through a fixing fixture 12 6. The lower end of the screw mandrel 6 is provided with a screw lifter 13, and the screw mandrel 6 is provided with a bracket 7. The bracket 7 is integrally formed with metal material and connected with the screw mandrel 6 through a screw nut. The bracket 7 is provided with a fixed bolt 5, which 5 is connected with the ladle cover 2 through the iron chain 3. The ladle nozzle 15 is provided on the ladle 1. The mouth of the ladle nozzle 15 is at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com