Water and electricity separation structure of argon arc welding torch water cooling system

A water-electricity separation and water-cooling system technology, applied in the direction of welding fittings, welding connection methods, etc., can solve the problems of cable rubber tube bursting, cooling water flow acceleration, etc., and achieve the effect of easy replacement, simple device and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

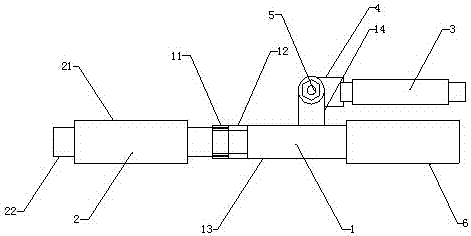

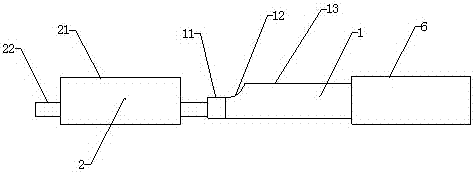

[0019] The water-electricity separation structure of the argon arc welding torch water-cooling system in this embodiment is mainly composed of the following parts: water-electricity separator 1 , water-cooling cable 2 , control side wire 3 , and cooling water pipe 6 .

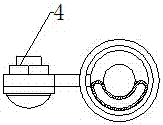

[0020] like Figure 1 to Figure 5 As shown, the electrical separator 1 is composed of a wire connection section 11, a transition section 12 and a water-electricity separation section 13; the water-electricity separation section 13 is a cylindrical conductor A, and the center of the cylindrical conductor A has a The cooling water channel extending in the axial direction is connected to the outer wall of the conductor A with a conductive ear plate 14 perpendicular to the conductor A; the wire connection section 11 is a conductor B with a circular arc in cross section. The outer end surface of B is provided with a cavity for clamping the wire, and the inner and outer diameters of the arc of the conductor B are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com