Machine tool

A processing machine and processing area technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as limited application fields, inability to process workpieces, and limited processing range of dual-spindle processing machines, so as to improve processing accuracy, Improve processing efficiency and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

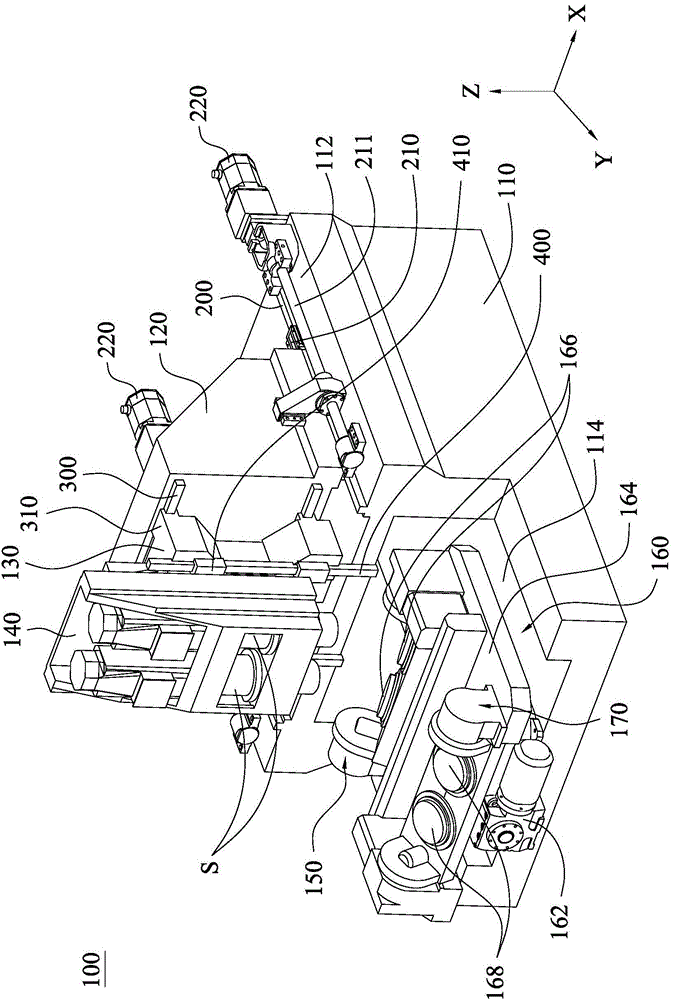

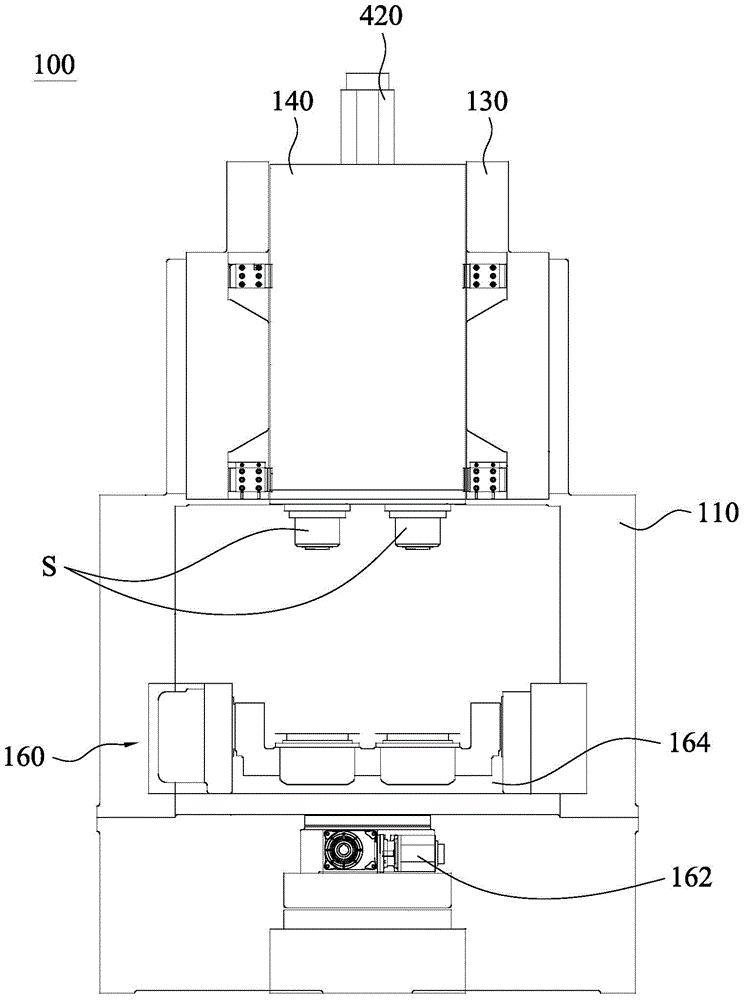

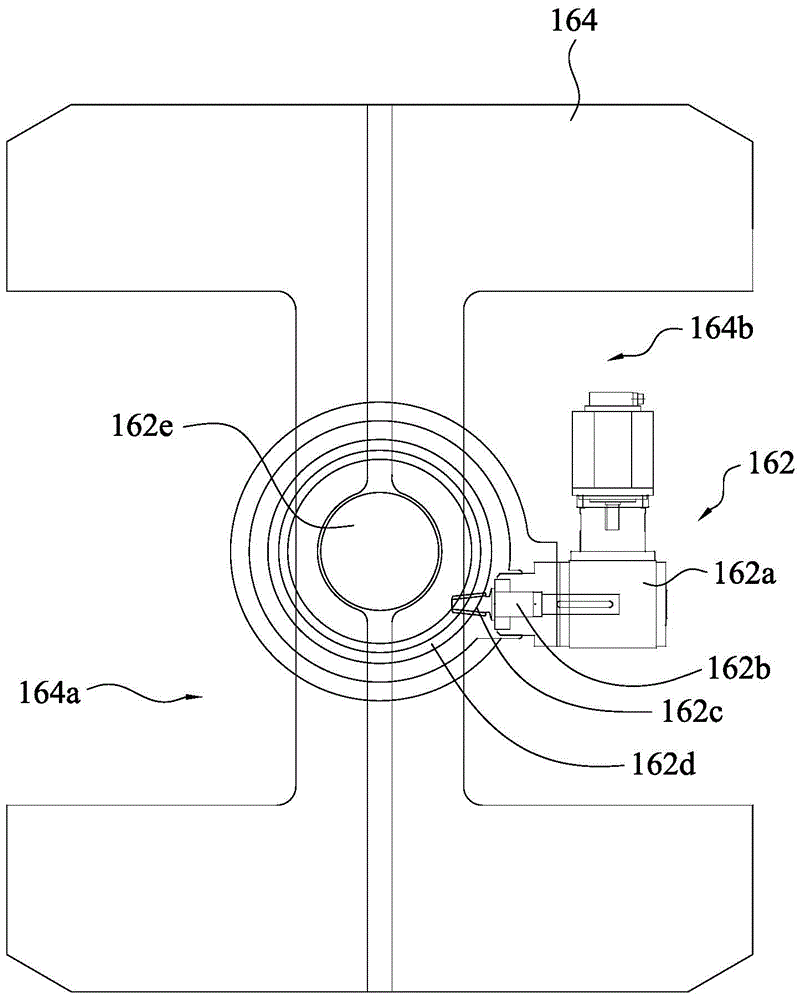

[0022] Please also refer to figure 1 as well as figure 2 , which is a device schematic diagram and a front view of a processing machine according to an embodiment of the present invention. In this embodiment, the processing machine 100 mainly includes a machine base 110 , a first shaft base 120 , a second shaft base 130 , a third shaft base 140 , at least two spindles S, and a rotary table 160 . Such as figure 1 As shown, the machine base 110 has a supporting portion 112 and a processing area 114 . The first shaft base 120 is disposed on the machine base 110 and can move along the Y-axis. In one embodiment, a slide rail 200 , a slide block 210 , a screw 211 and a motor 220 are disposed on the bearing portion 112 of the machine base 110 . Wherein, the first shaft seat 120 is disposed on the slider 210 . In this way, the motor 220 drives the screw 211 to drive the slider 210 to move on the slide rail 200 , so that the first shaft seat 120 can move along the slide rail 200 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap