Multifunctional vegetable cutter

A vegetable cutting machine, multi-functional technology, applied in the direction of metal processing, etc., can solve the problems of unadjustable vegetable cutting specifications, single function, inconvenient operation, etc., and achieve the effect of improving safety and sanitation performance, expanding functions, and increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

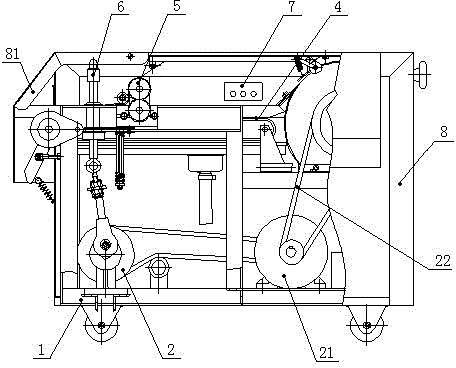

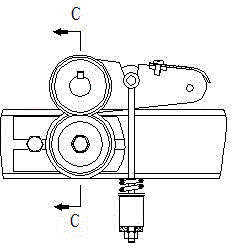

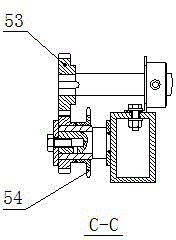

[0028] Figure 1a Shown is a schematic front view of the structure of the present invention.

[0029] Figure 1b Shown is the right view of the structure diagram of the present invention.

[0030] The present invention comprises a frame 1, a transmission mechanism 2, a slicing mechanism 3, a conveying mechanism 4, a vegetable pressing mechanism 5, a vertical knife shredding mechanism 6 and an electrical part 7, and one end of the double output shaft motor 21 of the transmission mechanism 2 drives the slicing mechanism 3 to rotate , the other end is connected with conveying mechanism 4 and vertical knife shredding mechanism 6 respectively and drives its work.

[0031] The whole machine of the present invention is a fully enclosed structure provided with a cover body 8. The vertical knife cover 81 above the vertical knife shredding mechanism 6 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com