Automatic seedling plate van based on double-chain transmission

An automatic carrier and double-chain transmission technology, which is applied in the field of seedling plate automatic carrier based on double-chain transmission, can solve the problems of high price and complex structure, and achieve the effect of low cost, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

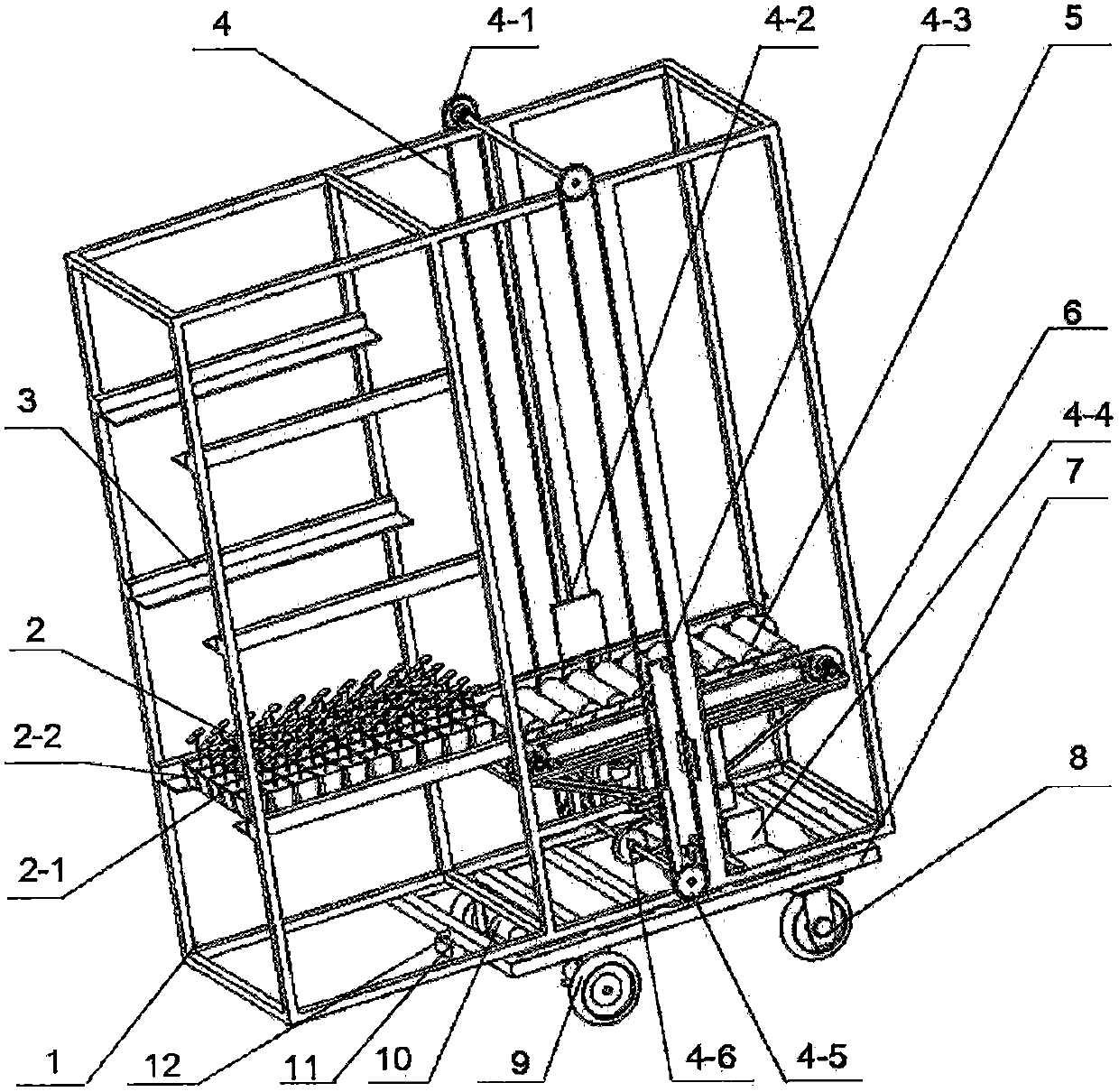

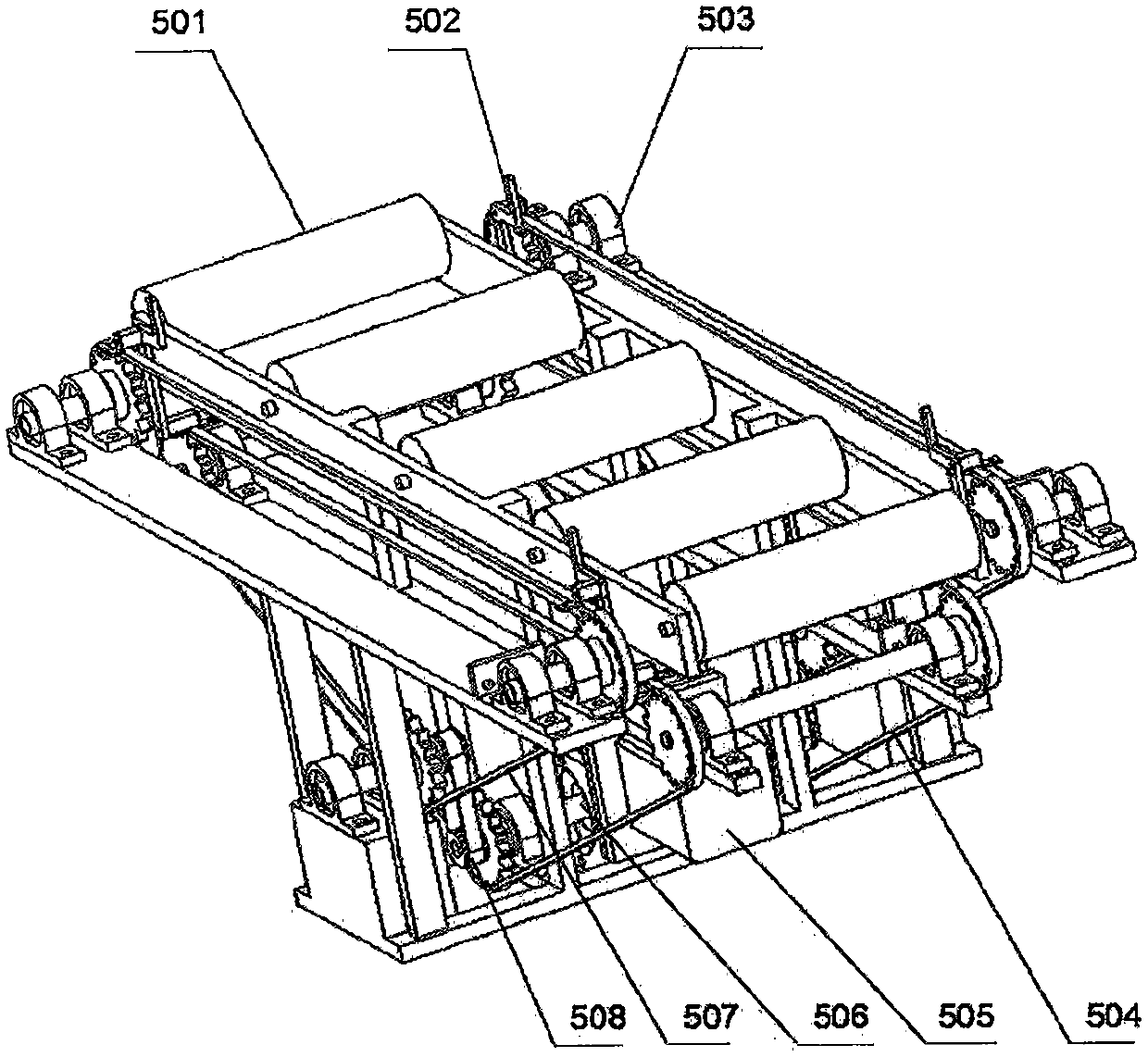

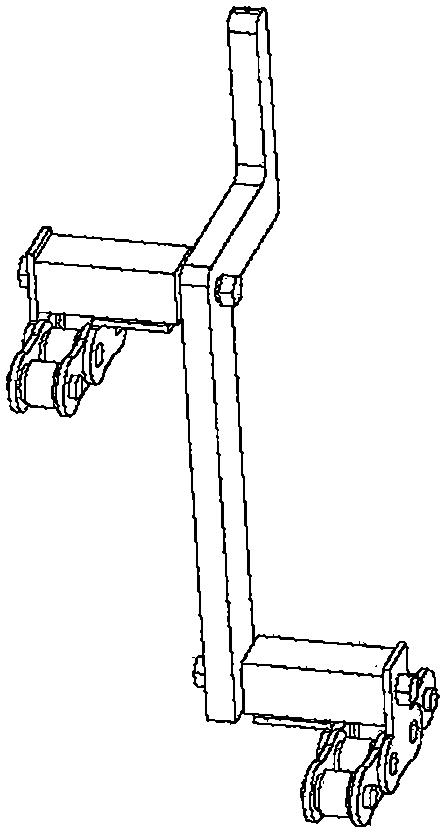

[0022] Refer to figure 1 , A seedling tray automatic transport vehicle based on double-chain transmission, including frame 1, picking and placing device 5, lifting device 4, placing mechanism 3, walking mechanism and control system, wherein the lifting device 4 is composed of a driven chain transmission mechanism 4-1, guide mechanism 4-2, Hall position sensor 4-3, reduction motor 4-4, active chain transmission mechanism 4-5, worm gear reducer 4-6, and the walking mechanism is composed of frame 7, driven wheel The mechanism 8, the driving wheel mechanism 9, the DC reduction motor 10, the magnetic navigation sensor 11 and the ultrasonic distance sensor 12. The chain transmission mechanisms on the left and right sides of the pick-and-place device 5 are fixed together with the guide mechanism 4-2 of the lifting device 4 through bearings and screws. When the lifting device 4 moves up and down, it can drive the pick-and-place device 5 fixed to it to move up and down. The position is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com