Roll-up dust-removing screen window

A technology of screen window and dust removal net, which is applied in the field of screen window, which can solve problems such as troublesome cleaning of screen window or replacement of window screen, inapplicability of dust removal screen window, and impact on air permeability, etc., to achieve the effect of improving cleanliness, saving time and effort in operation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

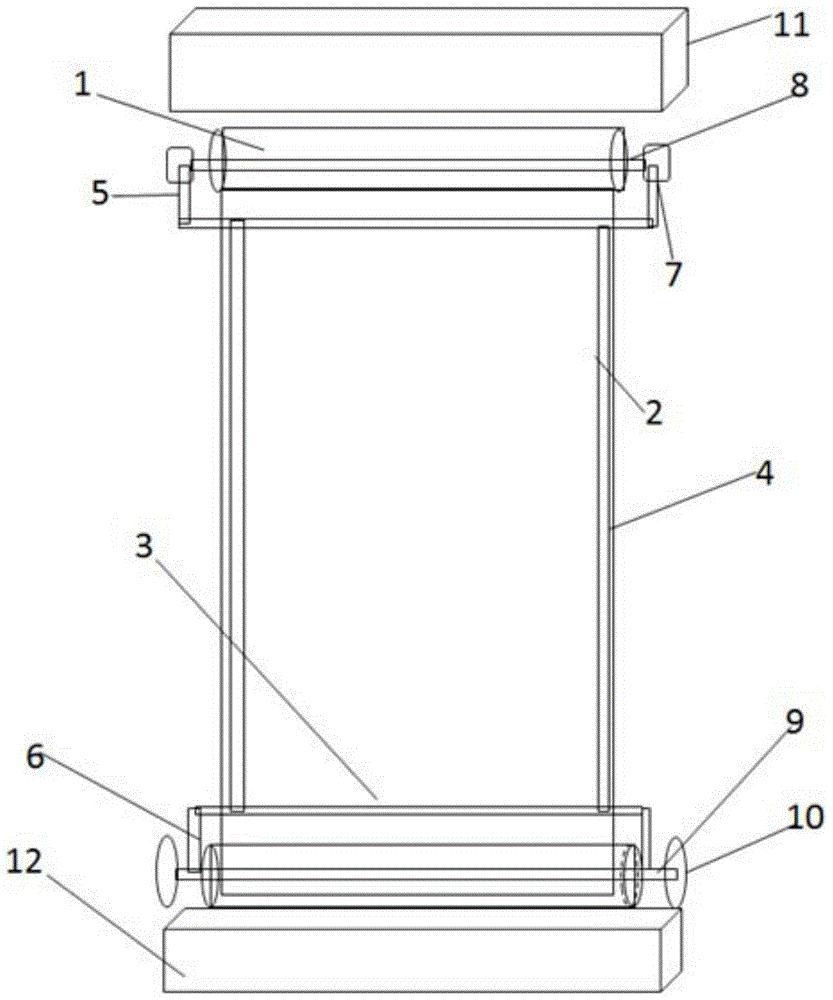

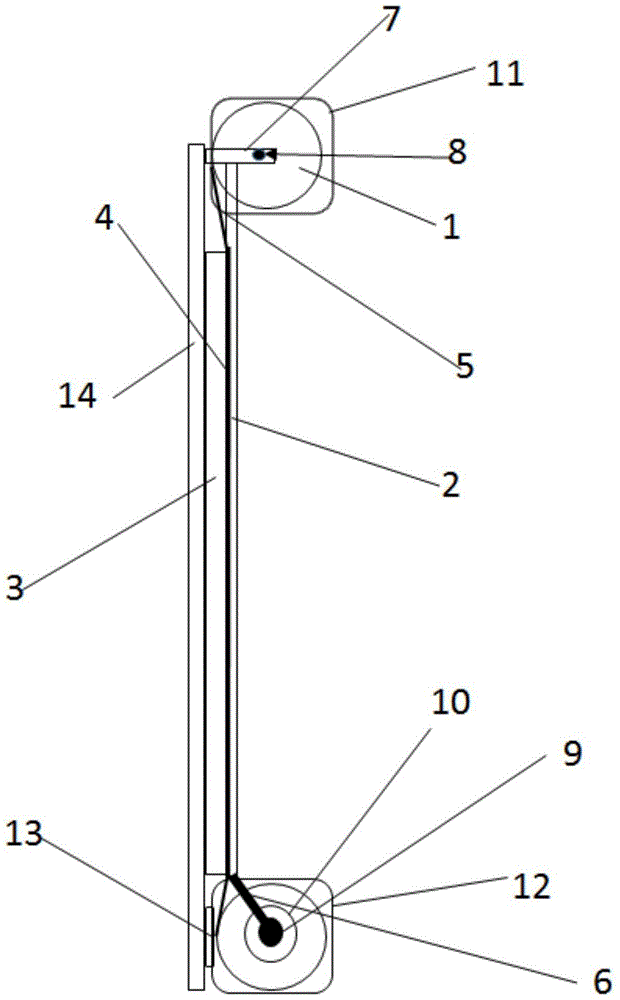

[0027] Such as Figure 1-2 As shown, a rolling type dust removal screen window includes a main frame 3 and a reel dust removal net 1, an upper reel 8 and a lower reel 9 are correspondingly arranged above and below the main frame 3, and the outer sides of the upper reel 8 and the lower reel 9 correspond to The upper support 7 and the lower support are set, and the shaft ends of the upper reel 8 and the lower reel 9 are correspondingly inserted into the upper support 7 and the lower support to form a rotational connection, and the end of the lower reel 9 passes through the lower support to form an extended end. Socket runner 10; The front side of main frame 3 is screen window surface, and rear side is installation surface, and installation surface is fixed on the window frame 14, and pressure frame 2 is set on the screen window surface, and pressure frame 2 and main frame 3 are all rectangular. The pressure frame 2 and the upper bracket 7 are connected by a suspension assembly, ...

Embodiment 2

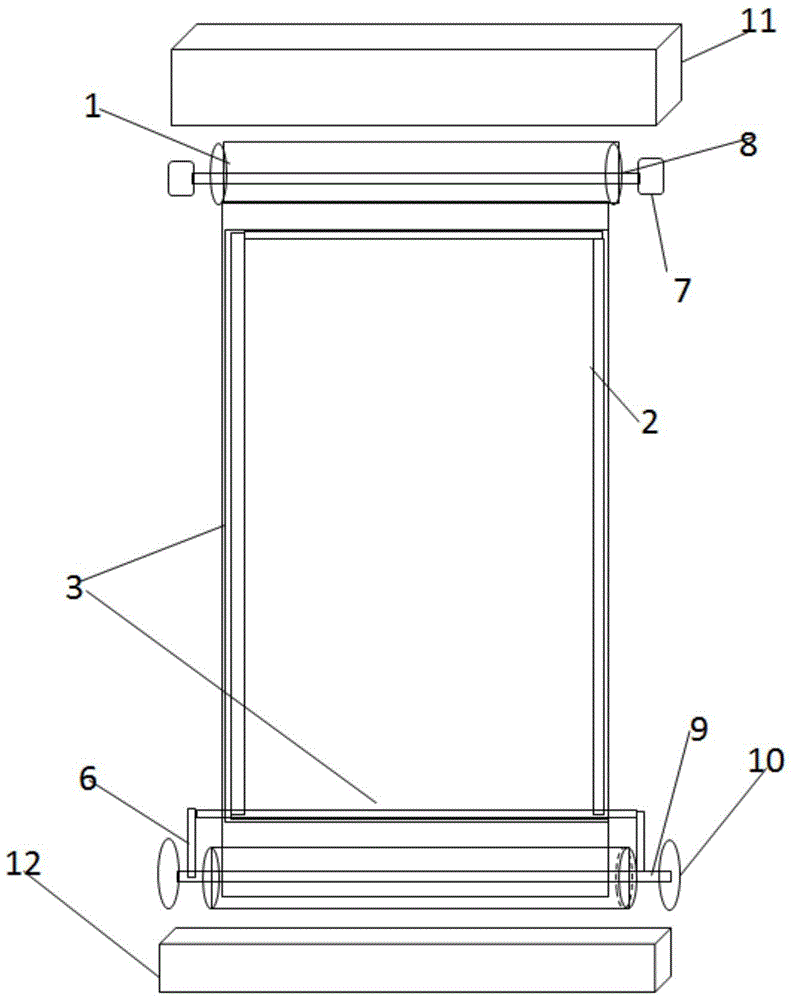

[0037] Such as Figure 3-4 As shown, a rolling type dust removal screen window includes a main frame 3 and a reel dust removal net 1, an upper reel 8 and a lower reel 9 are correspondingly arranged above and below the main frame 3, and the outer sides of the upper reel 8 and the lower reel 9 correspond to The upper support 7 and the lower support are set, and the shaft ends of the upper reel 8 and the lower reel 9 are correspondingly inserted into the upper support 7 and the lower support to form a rotational connection, and the end of the lower reel 9 passes through the lower support to form an extended end. Socket runner 10; The front side of main frame 3 is screen window surface, and rear side is installation surface, and installation surface is fixed on the window frame 14, and pressure frame 2 is set on the screen window surface, and pressure frame 2 and main frame 3 are all rectangular. The pressure frame 2 and the upper bracket 7 are connected by a suspension assembly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com