Underground condition wireless monitoring device

A wireless monitoring device and technology for conditions, applied in surveying, wellbore/well components, earth-moving drilling, etc., can solve the problems of only one set, unobtainable, unobtainable, etc., to achieve scientific and reasonable principles, friendly use environment, easy to use The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

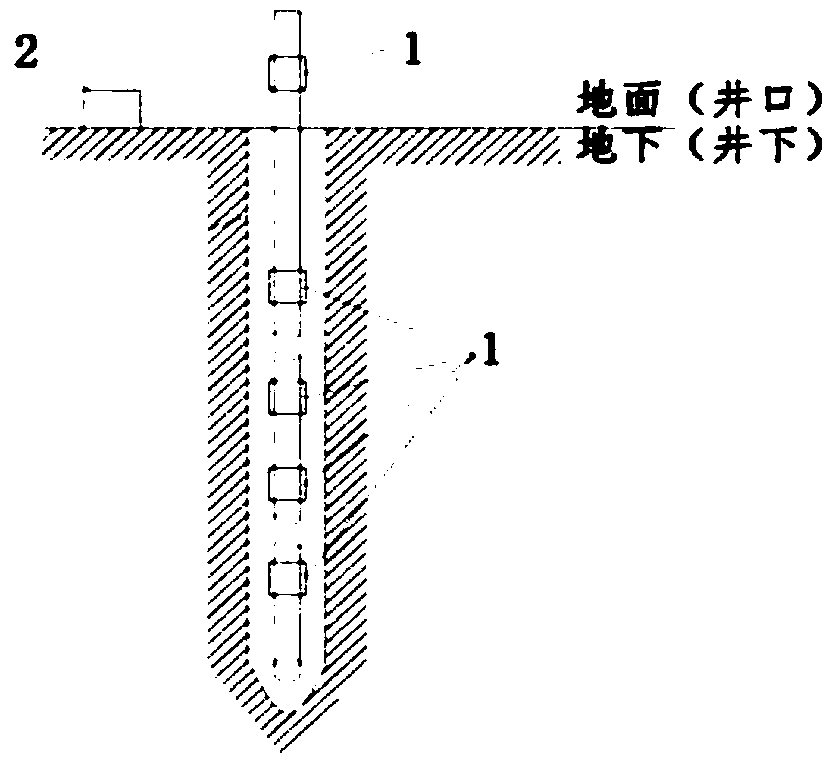

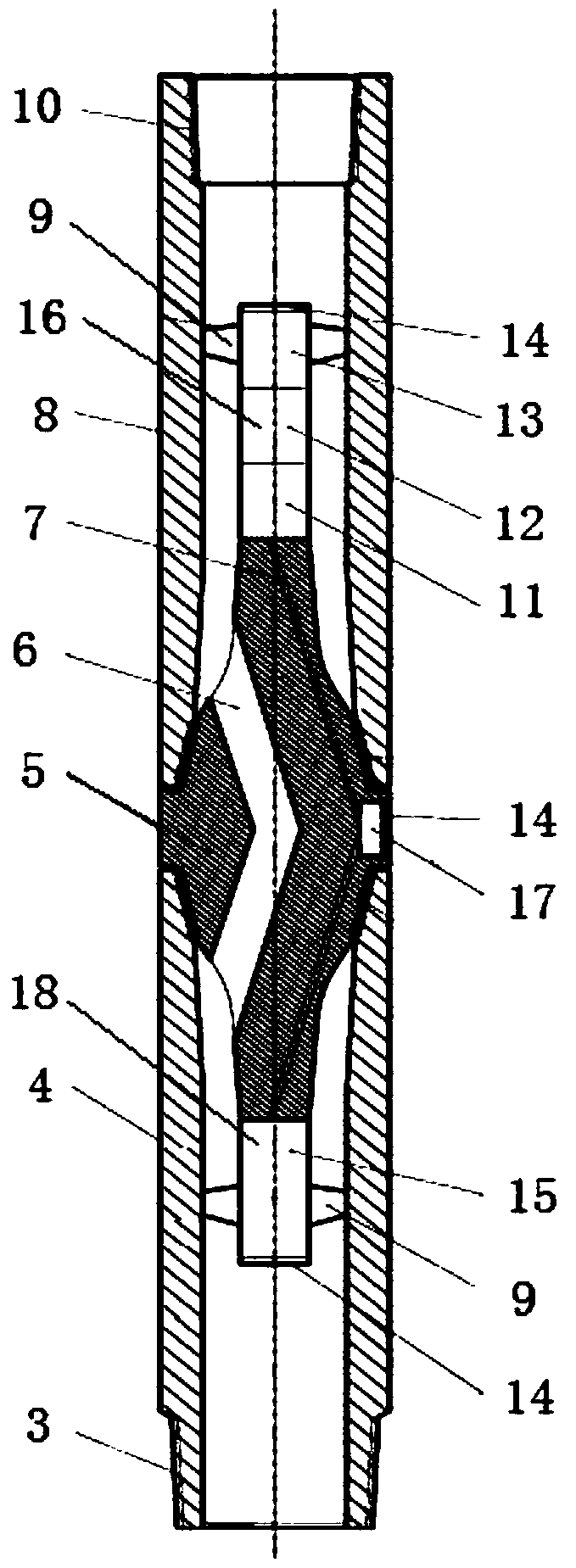

[0012] The main structure of the wireless monitoring device involved in this embodiment includes two functional parts of a monitoring unit 1 and a data processing terminal 2, the monitoring unit 1 and the data processing terminal 2 are connected through wireless communication; the monitoring unit 1 is composed of an external thread 3, a lower protective sleeve 4. Intermediate nipple 5, first through hole 6, second through hole 7, upper protective sleeve 8, centralizer 9, internal thread 10, sensor module 11, circuit module 12, battery module 13, cover 14, lower The instrument barrel 15, the upper instrument barrel 16, the groove 17, the transmitting transducer and the auxiliary circuit module 18 are combined; The end of the inner thread 10 is provided; the upper part of the intermediate short joint 5 is provided with an upper instrument barrel 16, and the inside of the upper instrument barrel 16 is provided with a battery module 13, a circuit module 12 and a sensor module 11 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com