Fluidized bed dryer for isovanillin production

A technology of fluidized bed drying and evanillin, which is applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of troublesome scraper method and hinder the drying and blowing of evanillin, and achieve improvement efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

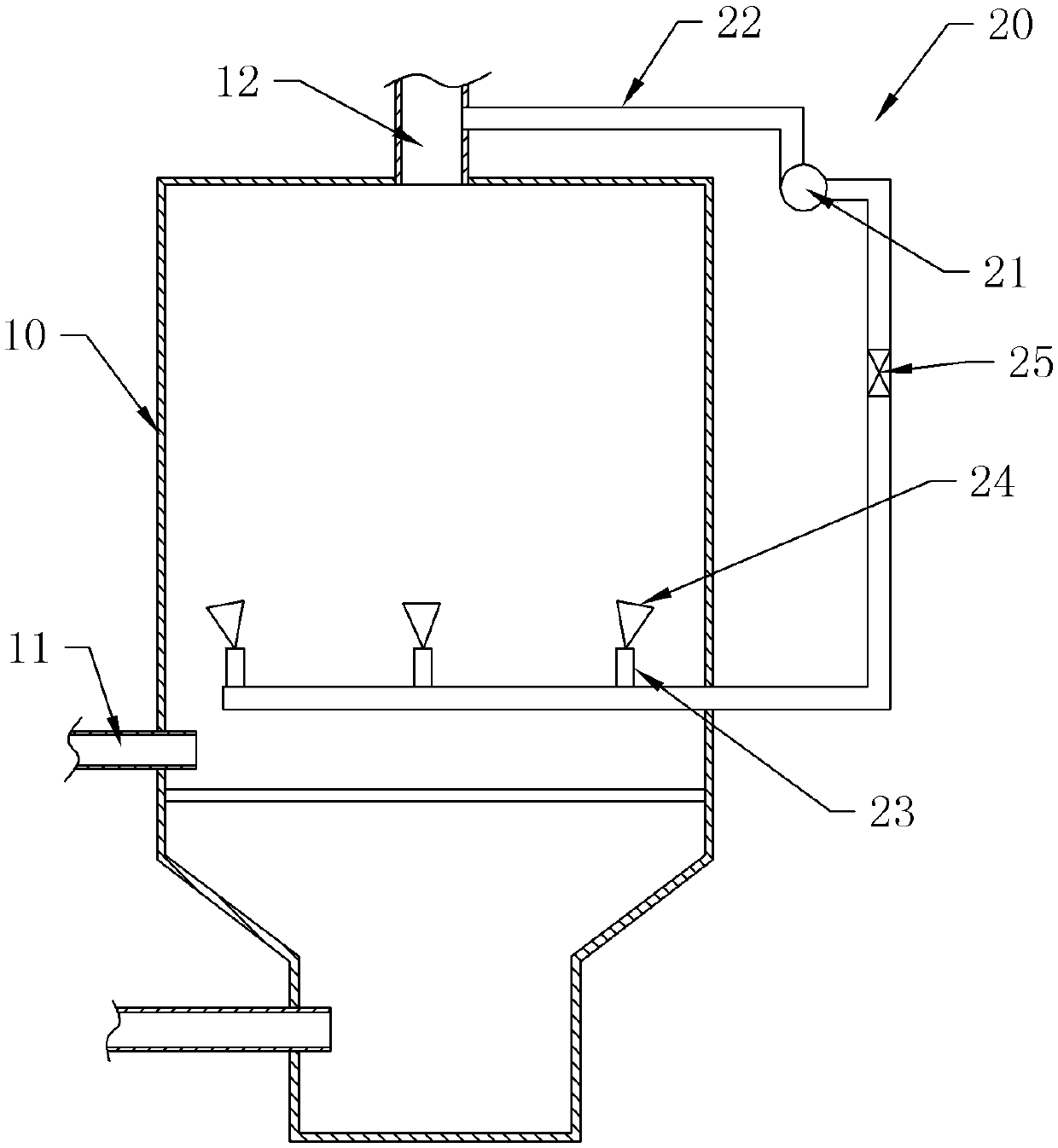

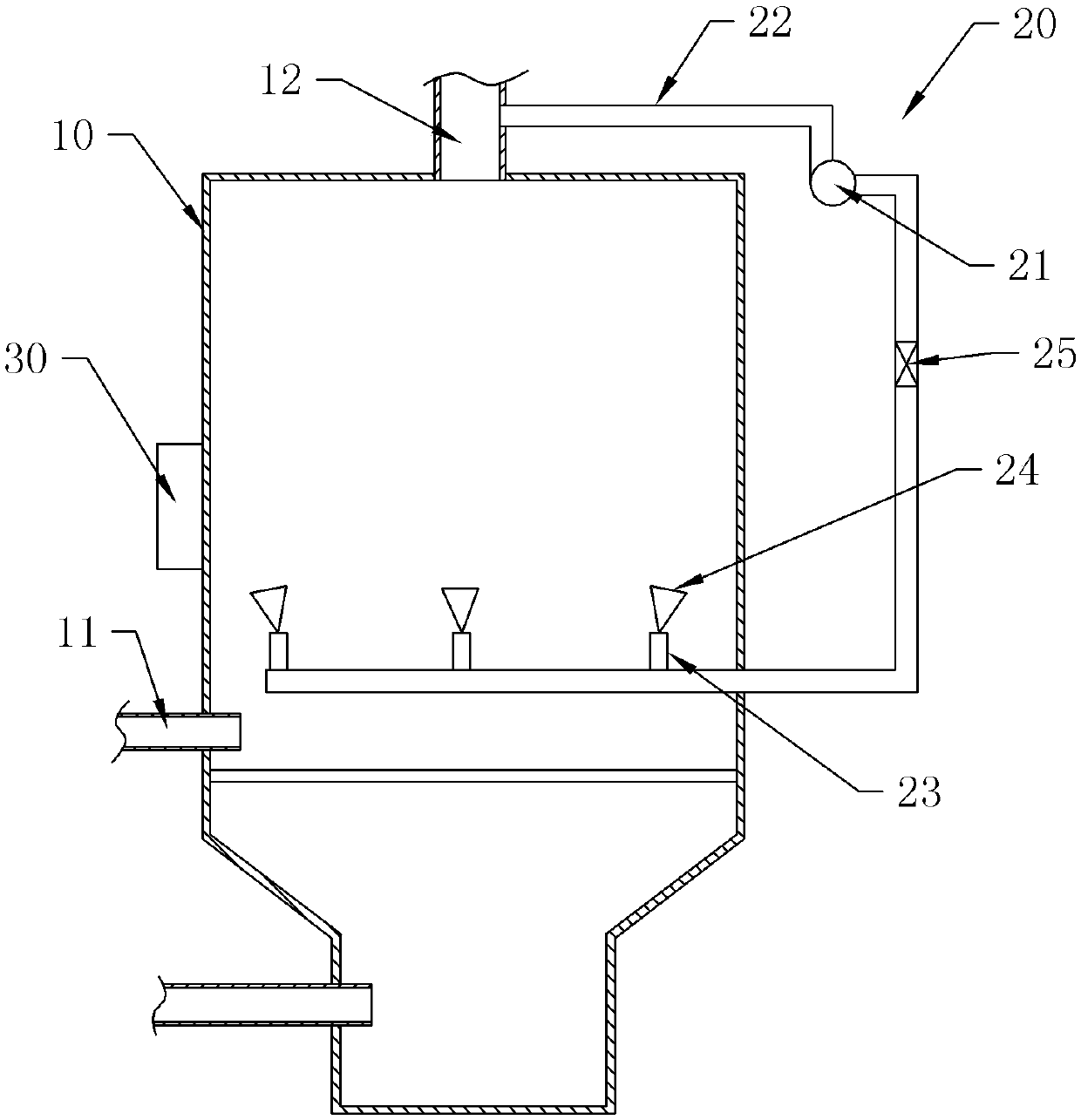

[0022] Such as figure 2 As shown, the difference from Embodiment 1 lies in that: in this embodiment, a vibrator 30 is fixed outside the dryer housing 10 by bolts. In the process of cleaning the adhesive ethvanillin on the inner wall of the dryer, the vibrator 30 is turned on, and the vibration of the vibrator 30 will also cause the ethvanillin stuck on the inner wall of the dryer housing 10 to fall off.

[0023] Specific working principle:

[0024] Such as figure 1 As shown, in specific use, the ethyl vanillin in the dryer is blown up by the hot air from bottom to top, and some of the blown up ethyl vanillin particles will stick to the inner wall of the dryer shell Above, the dried ethvanillin is discharged from the discharge port 12. Since one end of the pressure pipe 22 is connected to the discharge port 12, under the action of the blower 21, part of the acetylvanillin particles discharged from the discharge port 12 is subjected to pressure Pipe 22, six branch pipes 23, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com