Short-circuit-resisting transformer coils and preparation method therefor

A transformer coil and anti-short-circuit technology, which is applied in the field of transformers, can solve the problems of transformer coils that need to be further improved, the clamping force of insulating varnish clamps is limited, and the main empty channel is increased, so as to facilitate large-scale production and enhance short-circuit resistance. , Increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

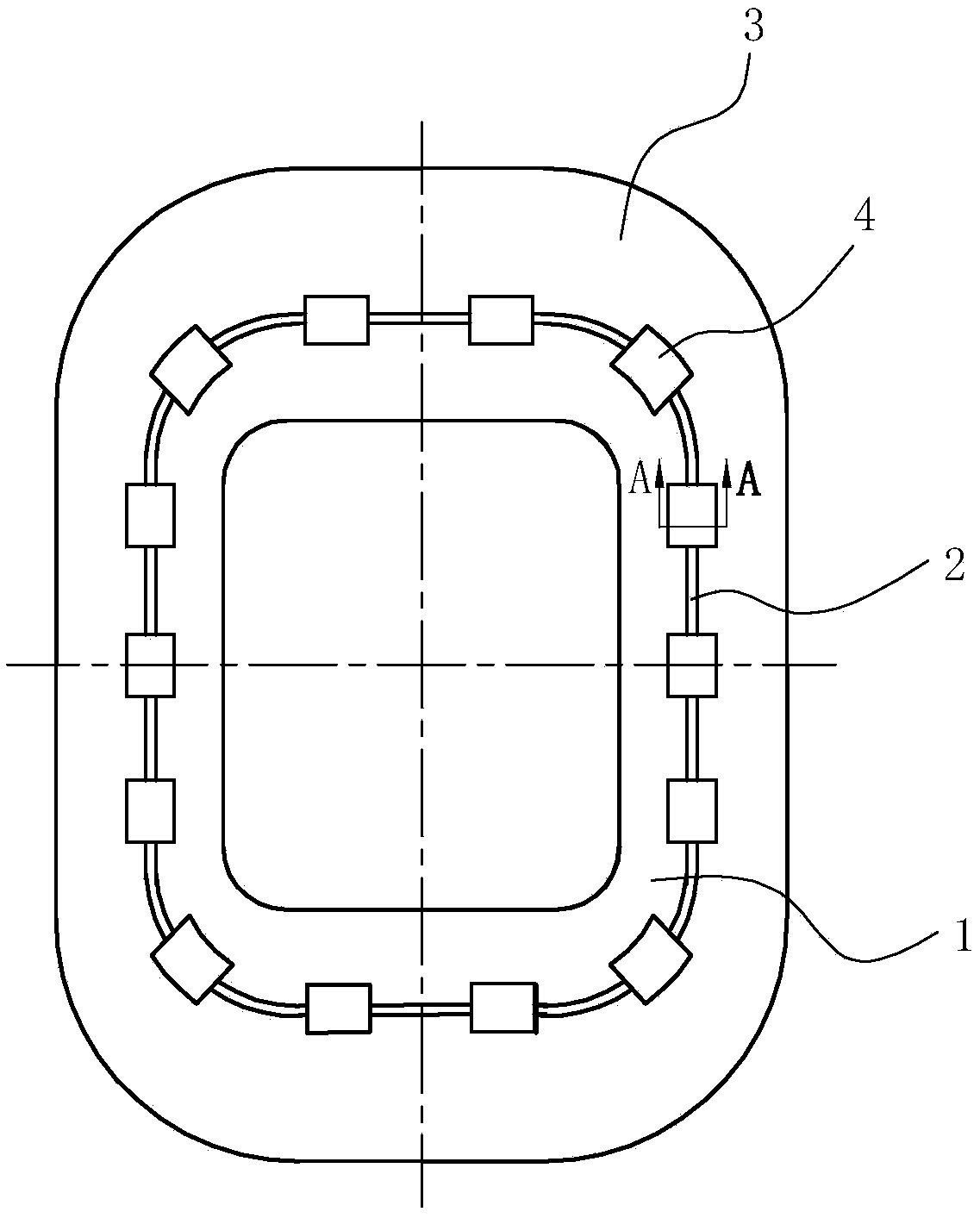

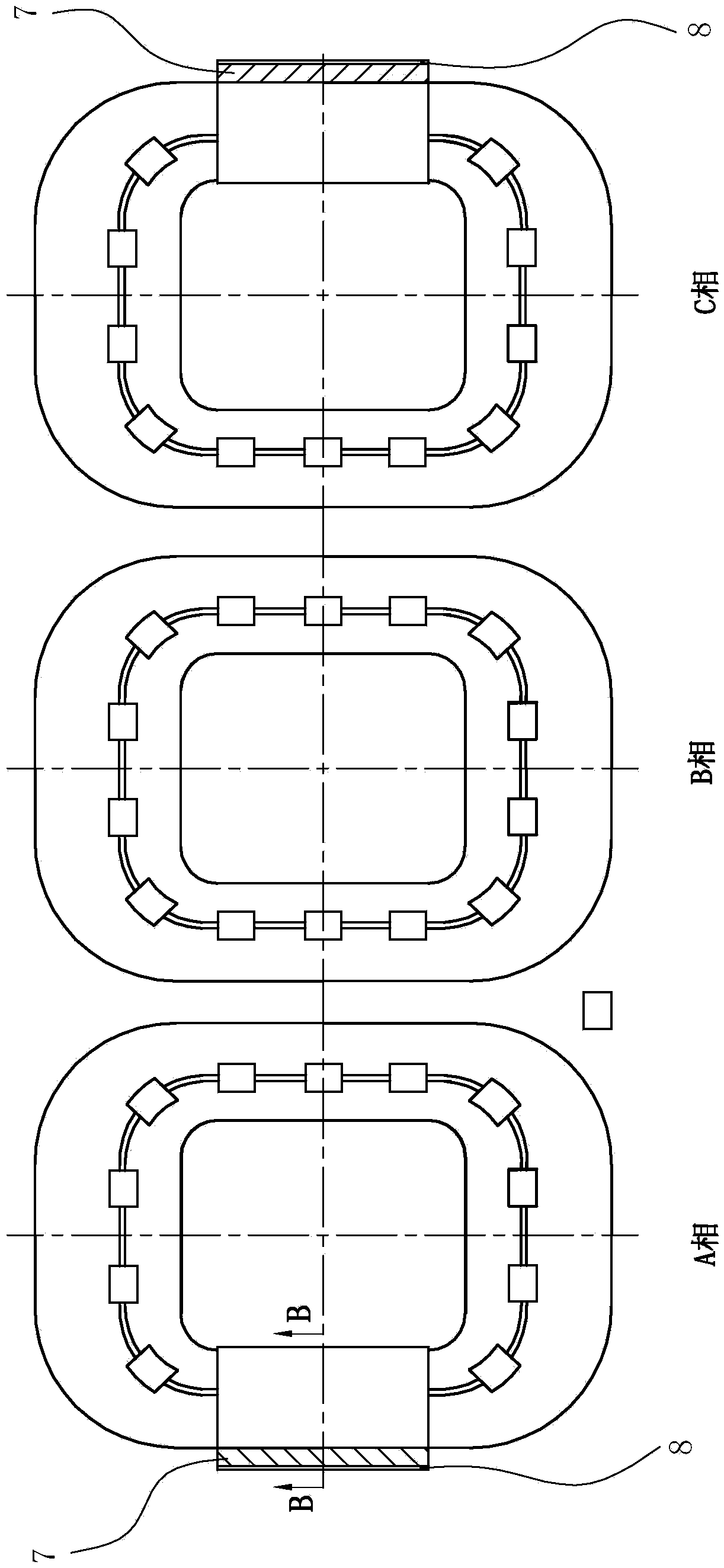

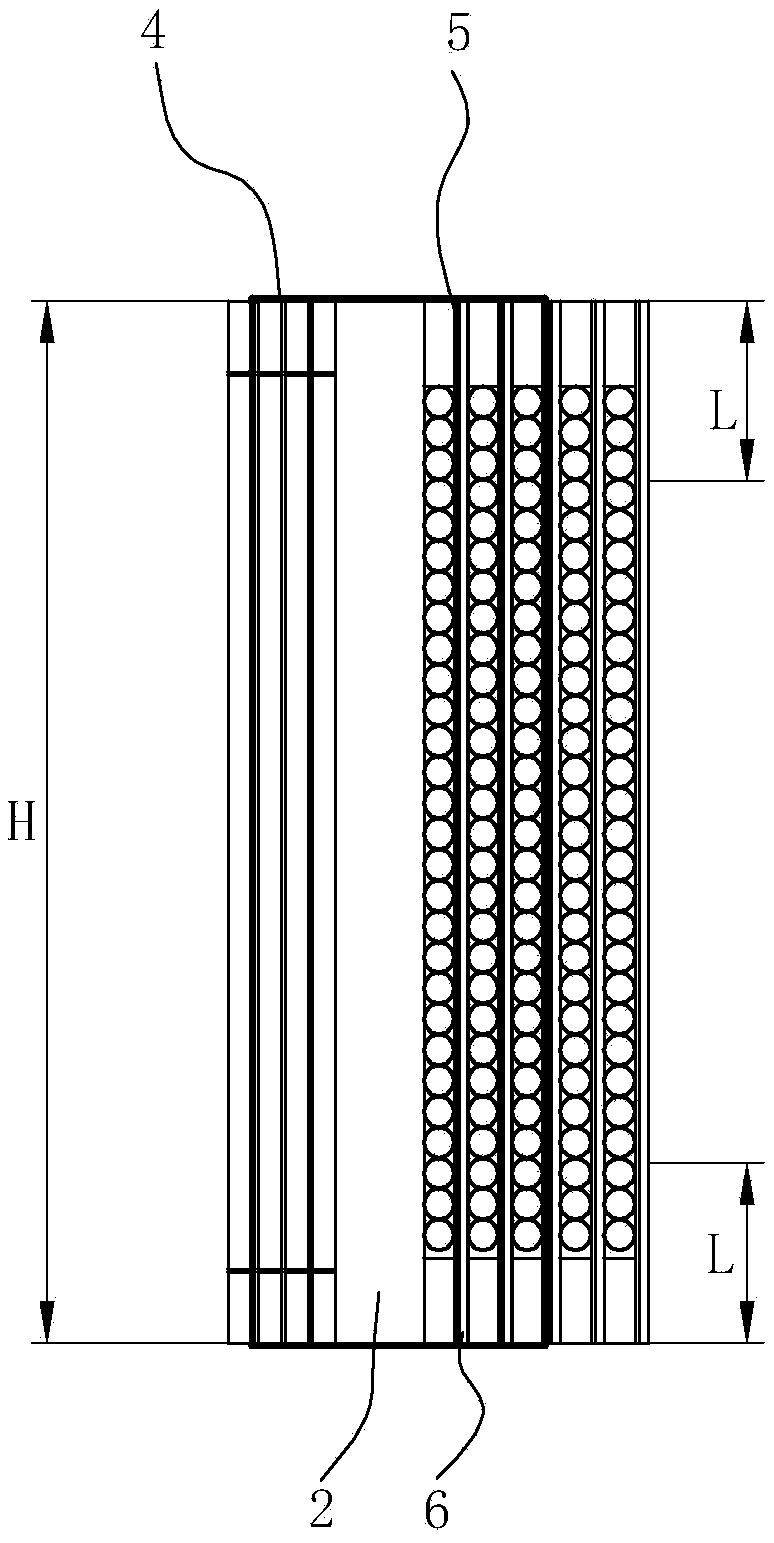

[0029] The embodiment of the present invention can be made as figure 1 The unidirectional transformer shown can also be made as figure 2 The three-phase transformer shown includes a low-voltage coil 1, a main space insulation 2 and a high-voltage coil 3 arranged sequentially from the inside to the outside, and also includes the last few layers of windings of the low-voltage coil, the main space insulation and The first few layers of windings of the high-voltage coil are tightened into one first insulating tape 4. The first insulating tape 4 can be made of non-alkali glass cloth or non-alkali glass fiber tape. Of course, the first insulating tape can also be made of other existing ones. Made of insulating reinforced material. When arranged, the first insulating strips 4 may be multiple, distributed along the coil circumferentially at interva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com