Electron source, X ray source and device using X ray source

An electron source and X-ray technology, which is applied in the field of X-ray sources, can solve the problems of affecting emission efficiency, waste of electron emission sources, and insufficient emission current intensity, and achieve the effect of reducing radiation dose and reducing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific approach 1

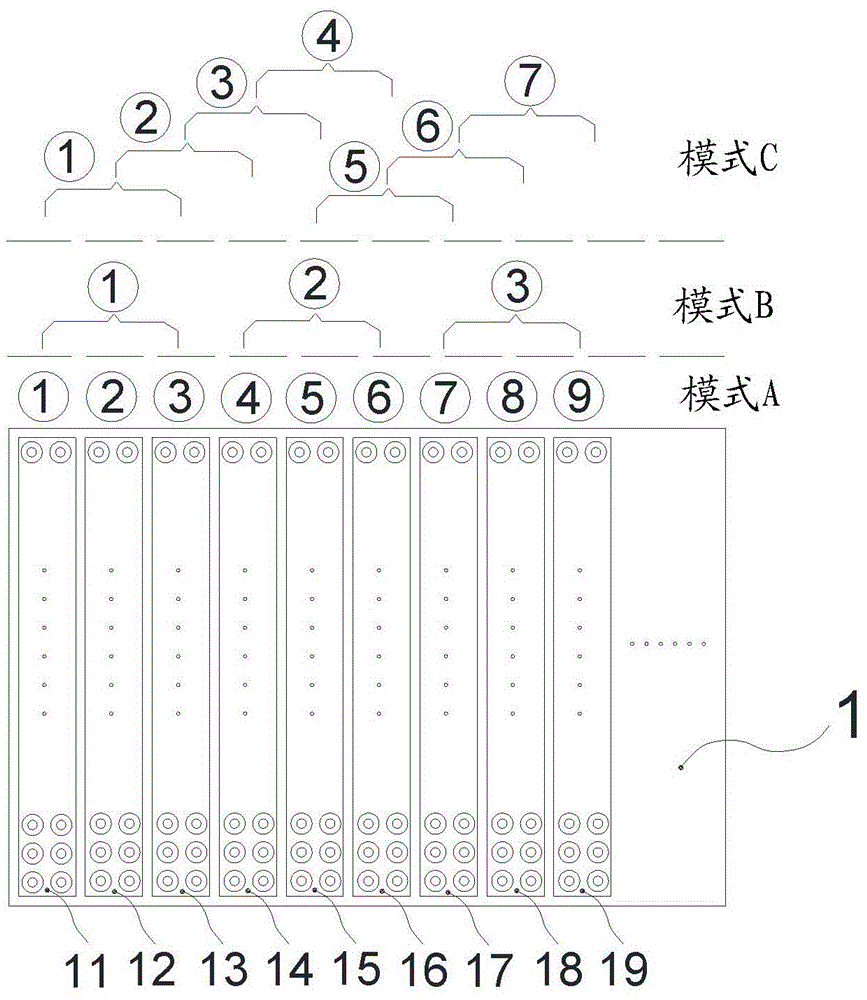

[0144] Specific scheme 1: There is one X-ray source, the X-ray source has an electron emission area to form an X-ray target point, and there are multiple detectors, forming a linear array or a planar array (also can be a planar detector). Some X-ray perspective imaging systems have a similar composition structure. The solution has simple structure, small volume and low cost, but the field emission X-ray source of the present invention has the advantages of low control voltage and fast starting speed.

specific approach 2

[0145] Specific plan two: one X-ray source, the X-ray source has two electron emission regions, the target materials of the two targets are different, and can alternately generate two X-ray beams with different energies, and there are multiple detectors to form a linear Arrays or planar arrays (also planar detectors), or further dual-energy detectors. The solution is simple in structure, small in size and low in cost. At the same time, through dual-energy imaging, the material identification ability of the detection object is increased.

specific approach 3

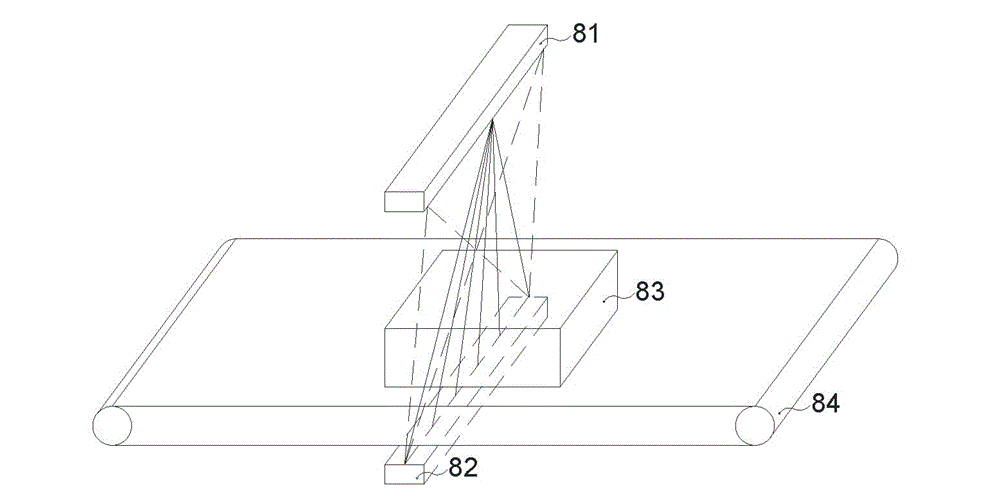

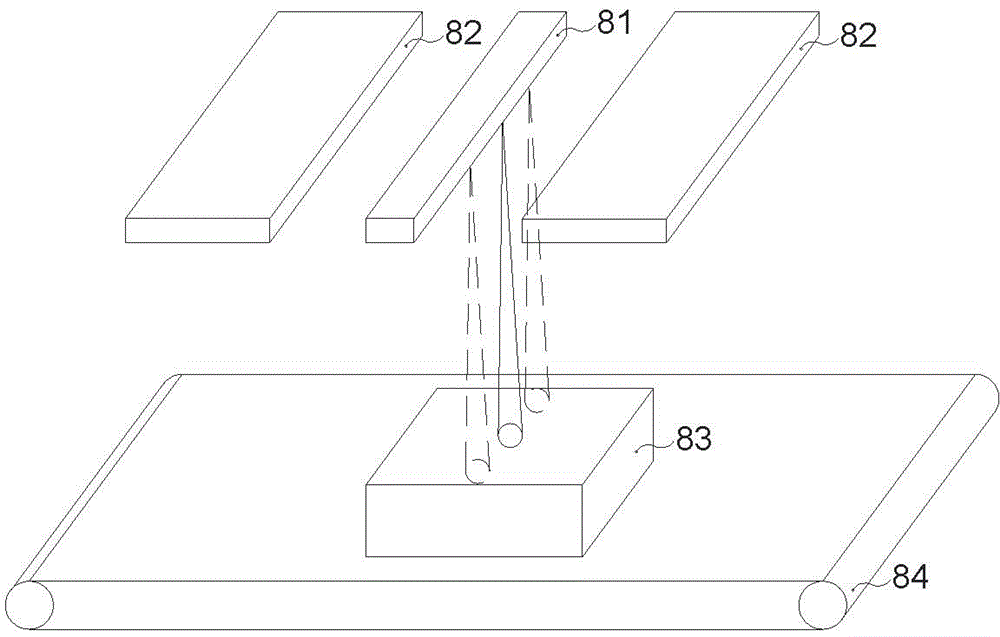

[0146] Specific scheme three: the X-ray source is a distributed X-ray source, the X-ray source has multiple X-ray targets, and multiple detectors, forming a linear array or a planar array (or a planar detector). Multiple target points perform perspective imaging on the detected object through different angles (positions), and finally a perspective image with multi-level information in the depth direction can be obtained. Compared with the multi-view system using multiple common X-ray sources, this scheme has a simple structure. Small size and low cost.

[0147] Specific solution 4: The X-ray source is a distributed X-ray source with multiple X-ray targets and one or a few detectors. Through the "reverse" imaging principle, a perspective image is obtained. The feature of this solution is that the number of detectors is reduced and the cost is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com