A fiber cooling head suitable for high power semiconductor laser fiber coupling modules

A fiber coupling and semiconductor technology, applied in the field of laser technology, can solve the problems of user passiveness, low module integration, long cycle, etc., and achieve the effects of low cooling water requirements, easy integration and miniaturization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

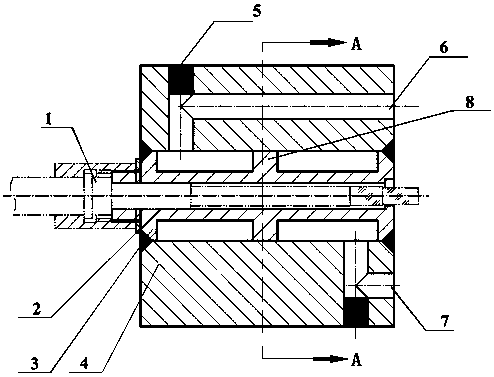

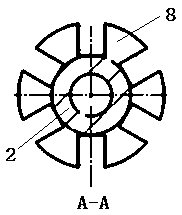

[0023] Such as figure 1 The optical fiber cooling head and the module shown are integrated processing, and the fiber cooling head waterway is fixed to the module shell with threads, and the waterway interface matching the cooling head water inlet and water outlet is left on the module shell, the fiber optic cooling head waterway and the module waterway Tightly connected through the waterproof pressure ring. The cooling water first flows through the water channel of the module to cool the laser chip, then enters the inner cavity of the cooling head through the water inlet, flows through the heat dissipation channel in the inner cavity to cool the target optical fiber, and finally returns the water to the cooling water return channel of the fiber coupling module through the water outlet, and completes the process. For the cooling of lasers and optical fibers in the system, this method makes the system more compact and simple.

Embodiment 2

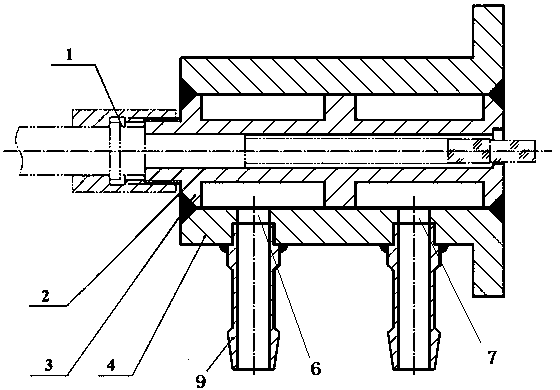

[0025] combine figure 2 This embodiment will be described. The difference between this embodiment and Embodiment 1 is that in this embodiment, the optical fiber cooling head is passed through water alone, and can be used as a component alone, and has lower requirements on the cooling water used. The faucet of this solution is set on the water inlet and the water inlet, and adopts quick-connect joints, which are easy to transfer quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com