Radio frequency laser with cylindrical surface collimating mirror

A technology of collimating mirrors and lasers, which is applied in the field of radio frequency lasers, can solve the problems of wasting laser energy, increasing processing costs, and reducing the service life of lasers, and achieves the effects of reducing processing costs, prolonging service life, and improving laser processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

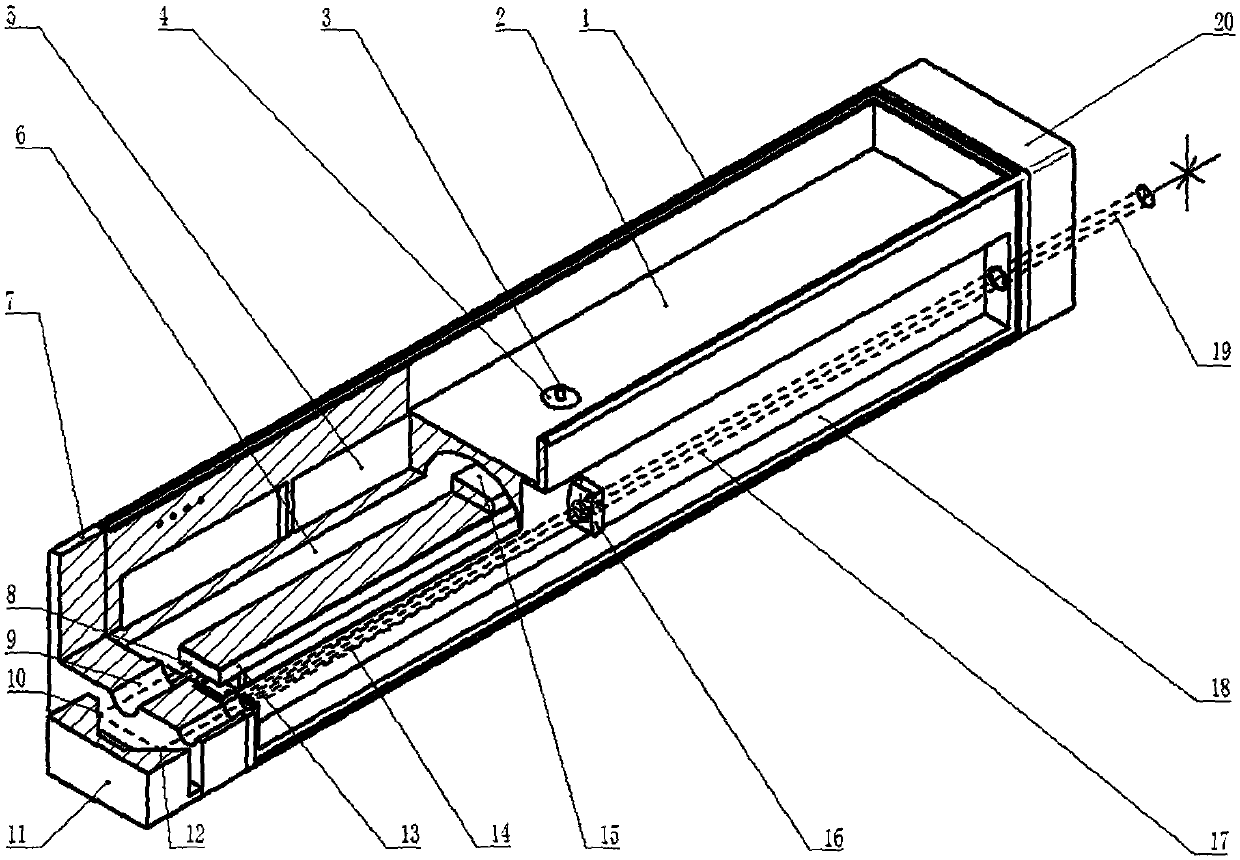

[0021] A radio frequency laser installed with a cylindrical collimator mirror according to an exemplary embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

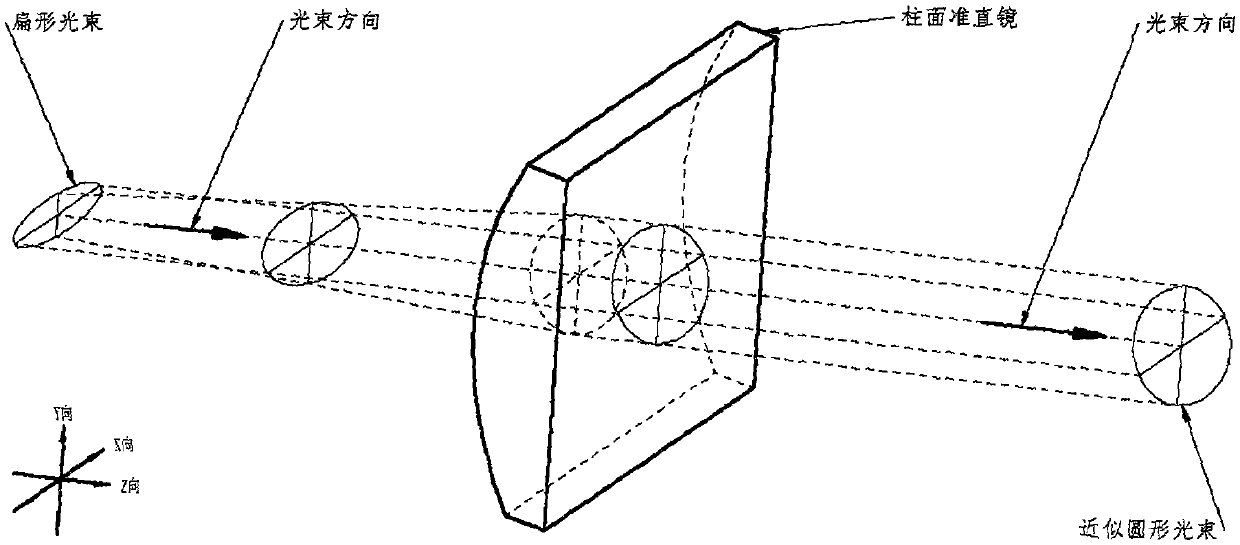

[0022] like figure 1 As shown, the laser beam is output from the laser cavity through the laser output window. At this time, the laser beam is flat, and its characteristic is that the beam divergence angle in the long direction is close to zero, and the beam divergence angle in the flat direction is obvious. On the optical path of the laser beam, When the flat beam diverges to be approximately equal to the long beam, this position is the best position for the cylindrical collimator to shape the laser beam. The shaped laser beam is approximately circular, and the beam is output in parallel.

[0023] figure 2 An axonometric view of a radio frequency laser mounted with a cylindrical collimating mirror is shown according to an example embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com