Patents

Literature

30results about How to "Improve the effect of laser processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

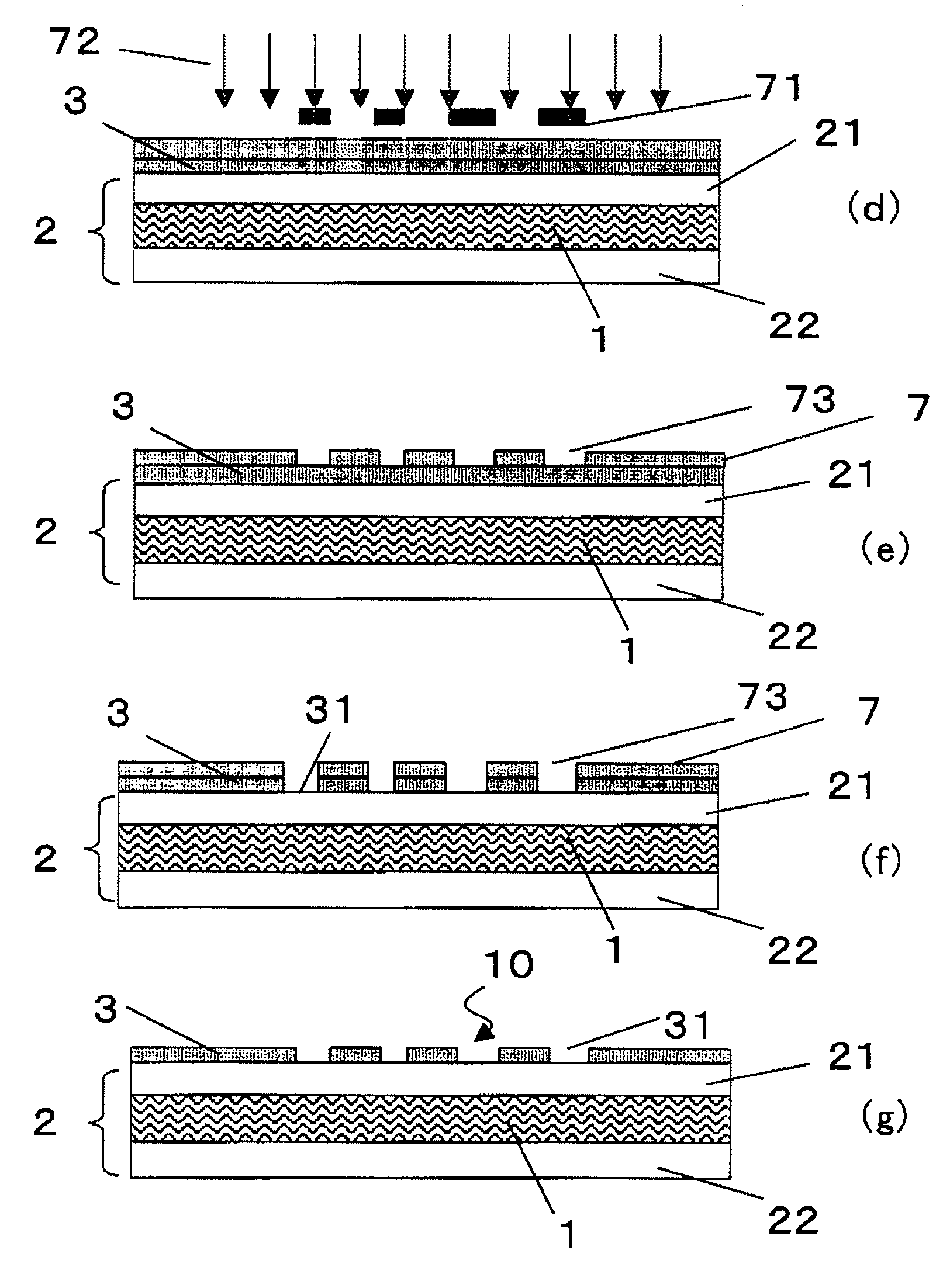

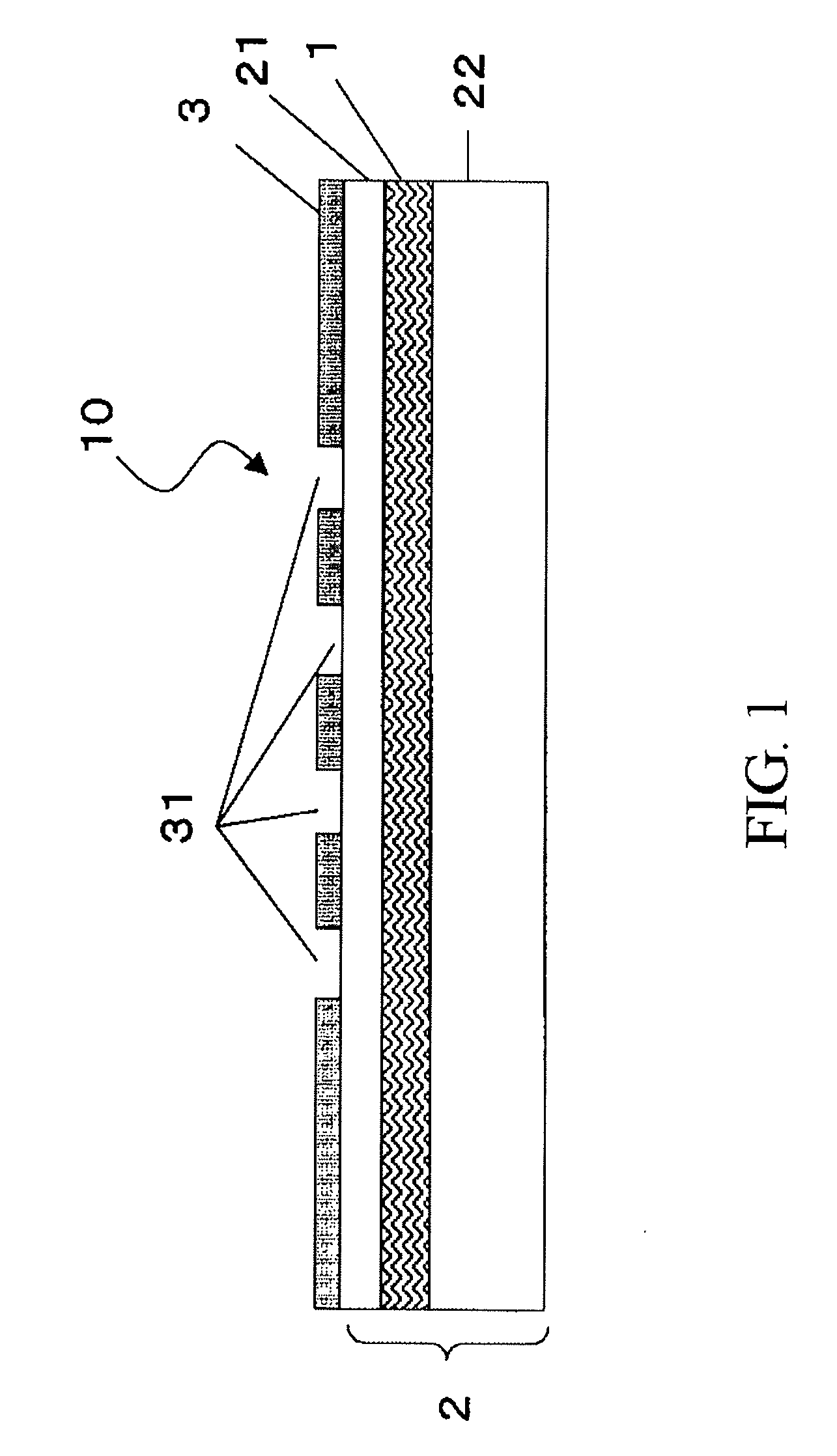

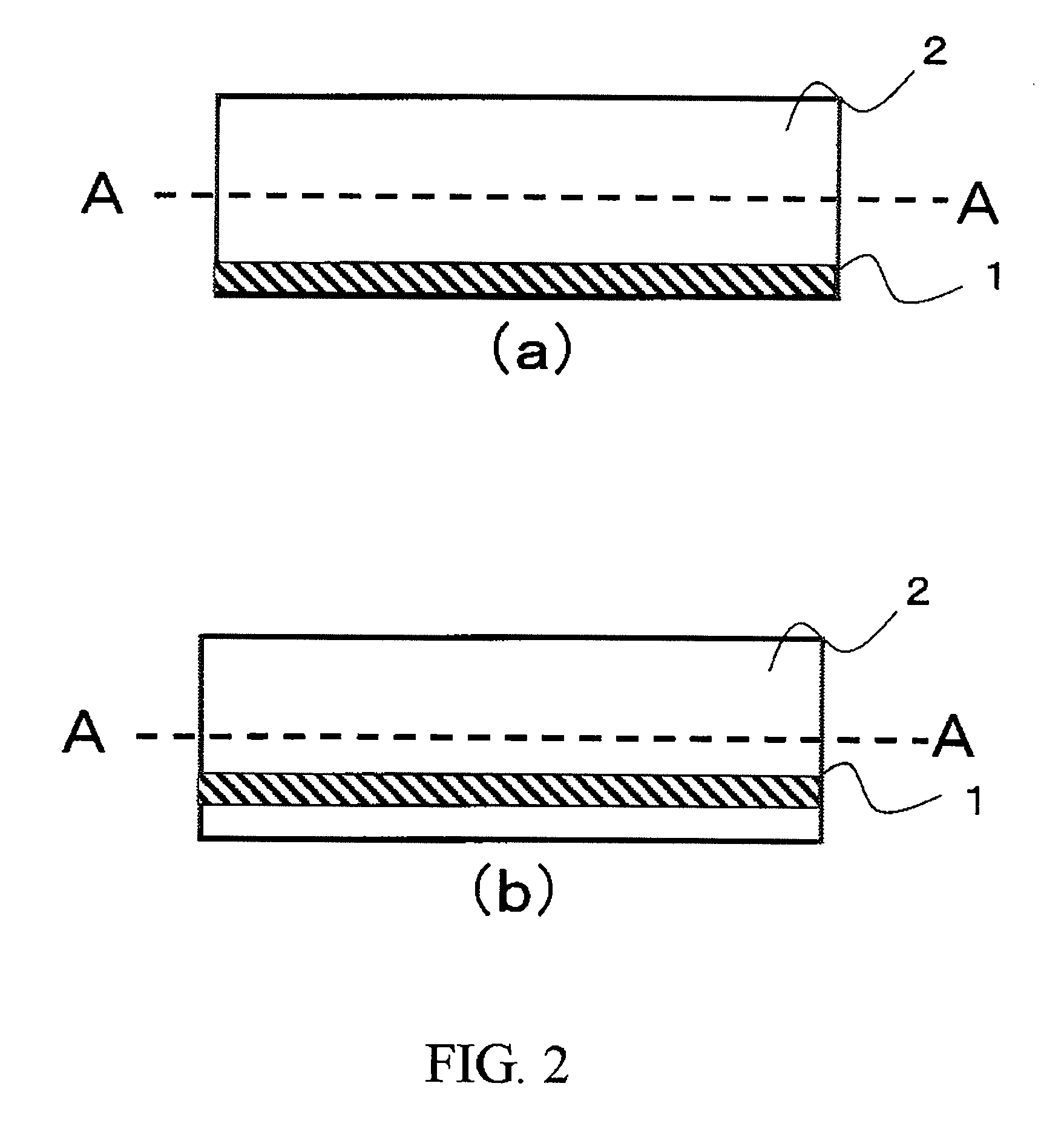

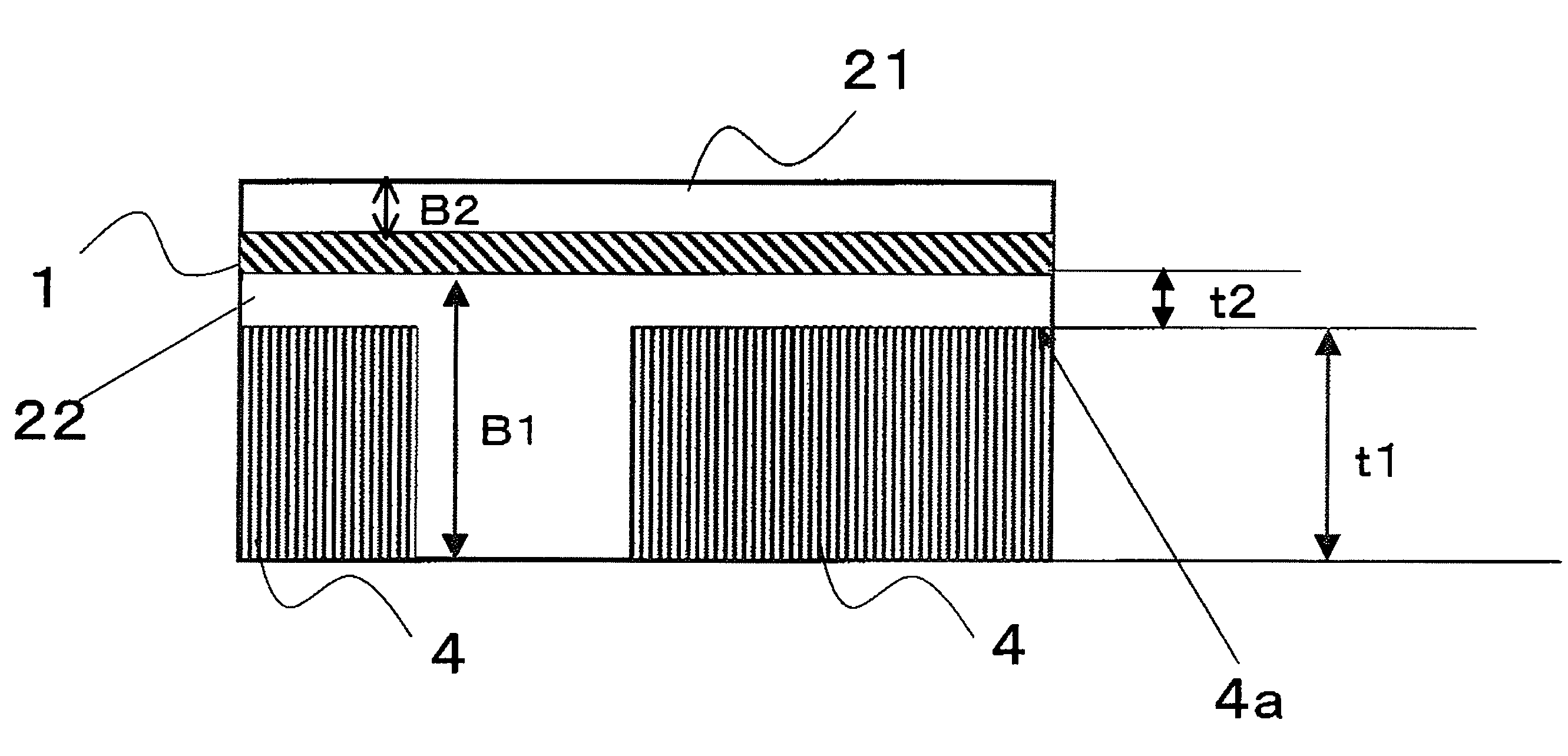

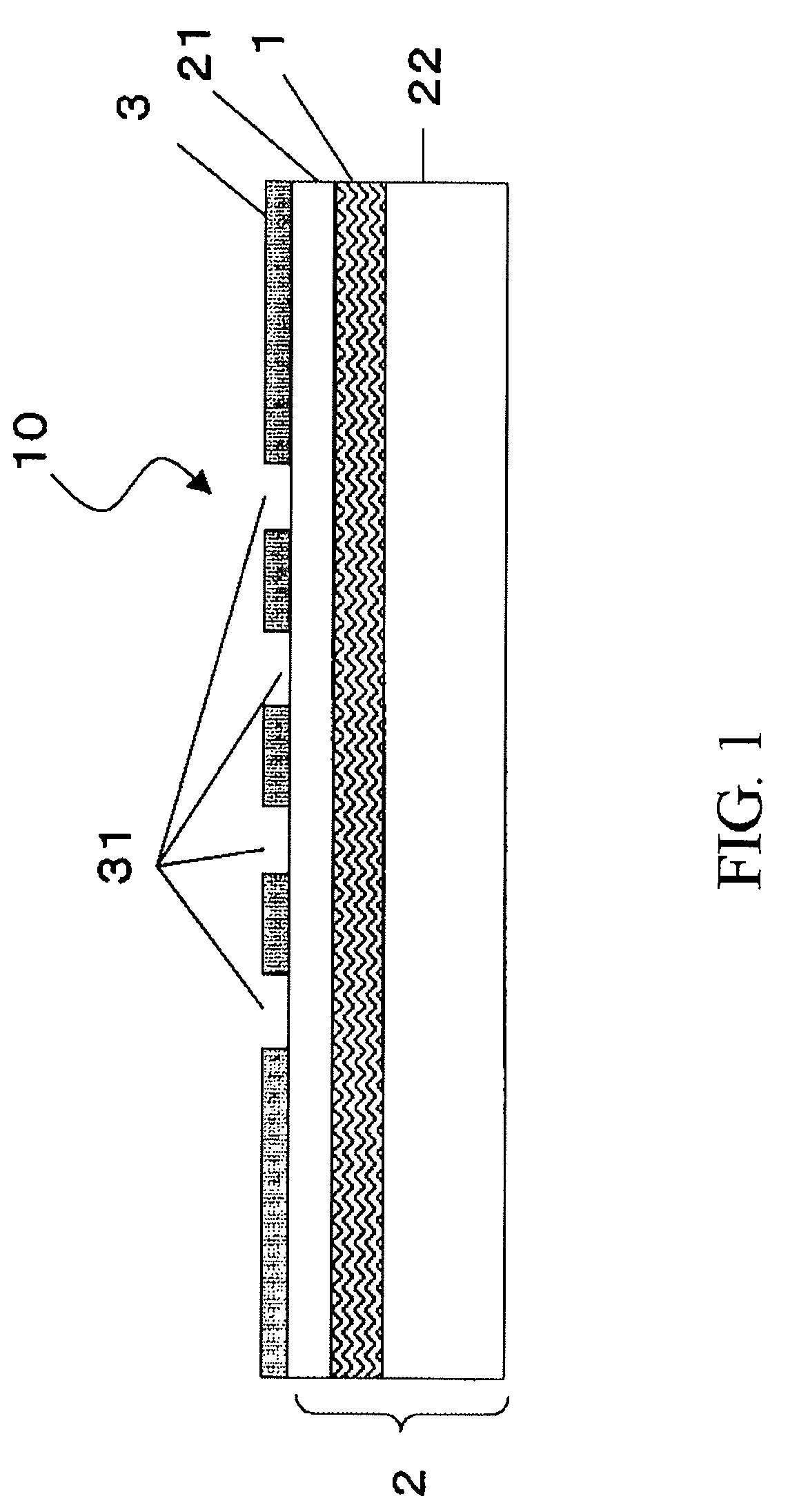

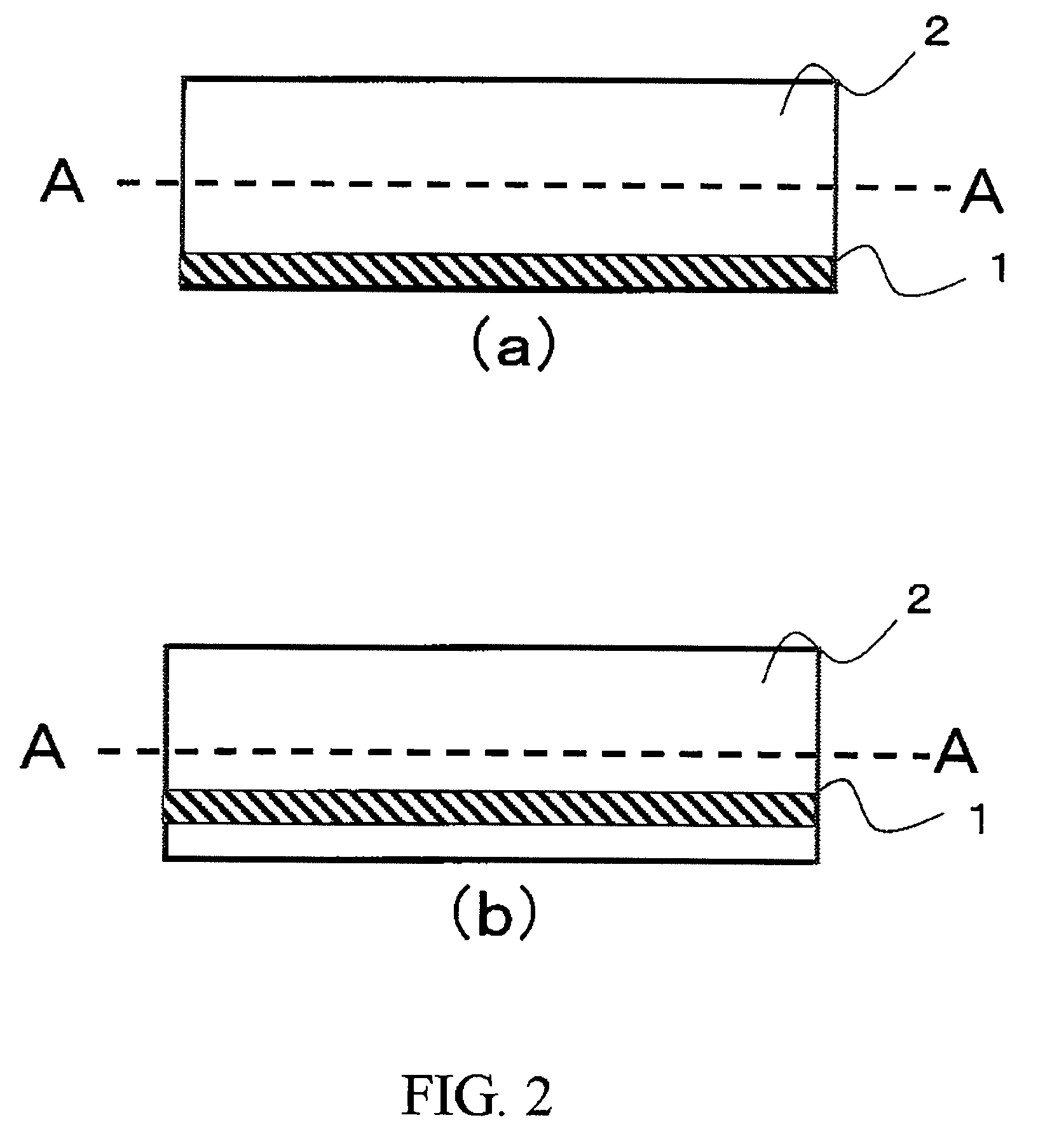

Laminated body, method of manufacturing susbtrate, substrate, and semiconductor device

InactiveUS20100044081A1Thin thicknessSuppress generationSemiconductor/solid-state device detailsSolid-state devicesFiberDevice material

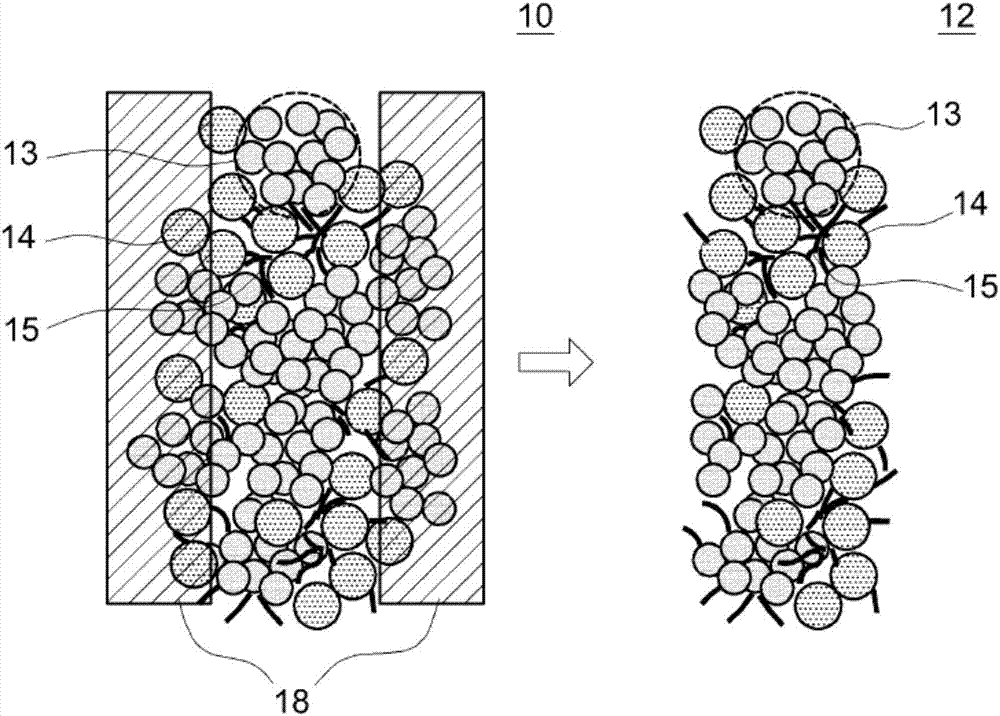

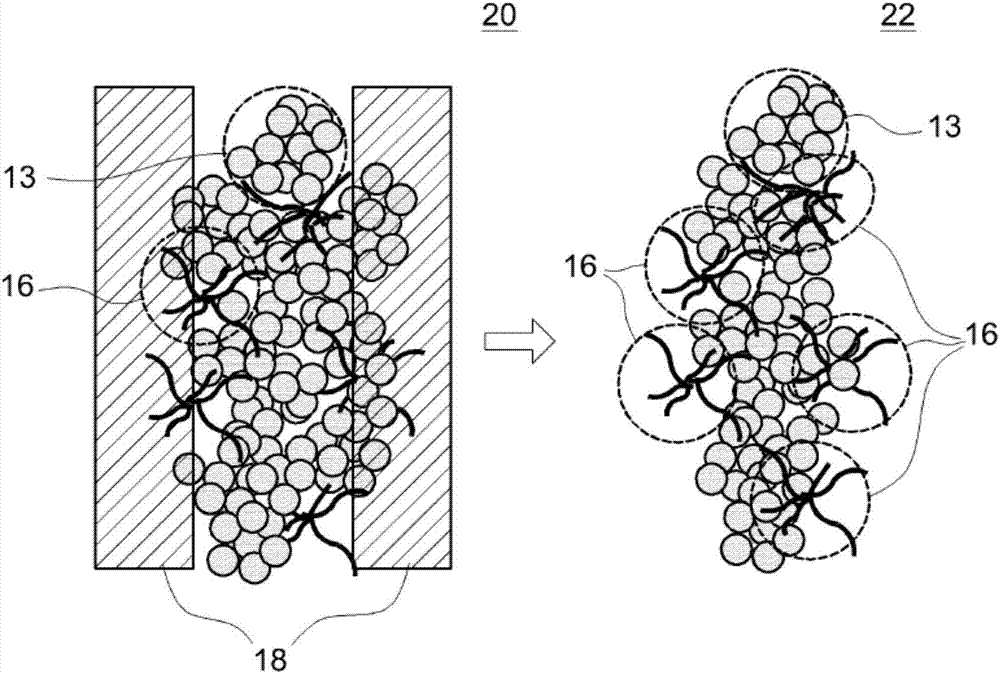

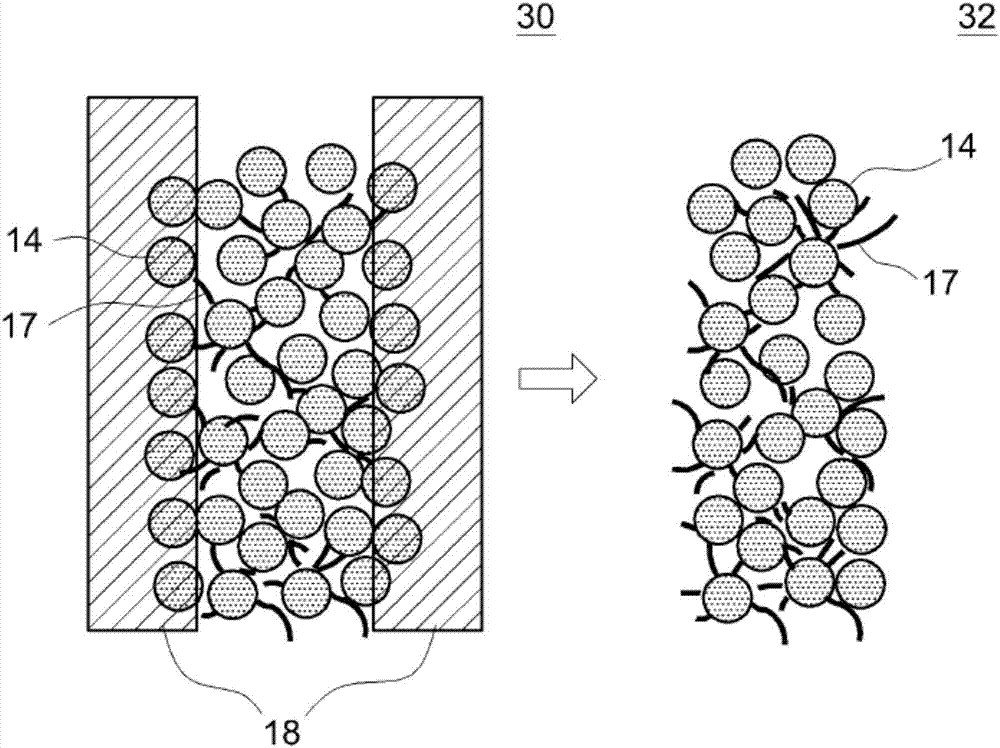

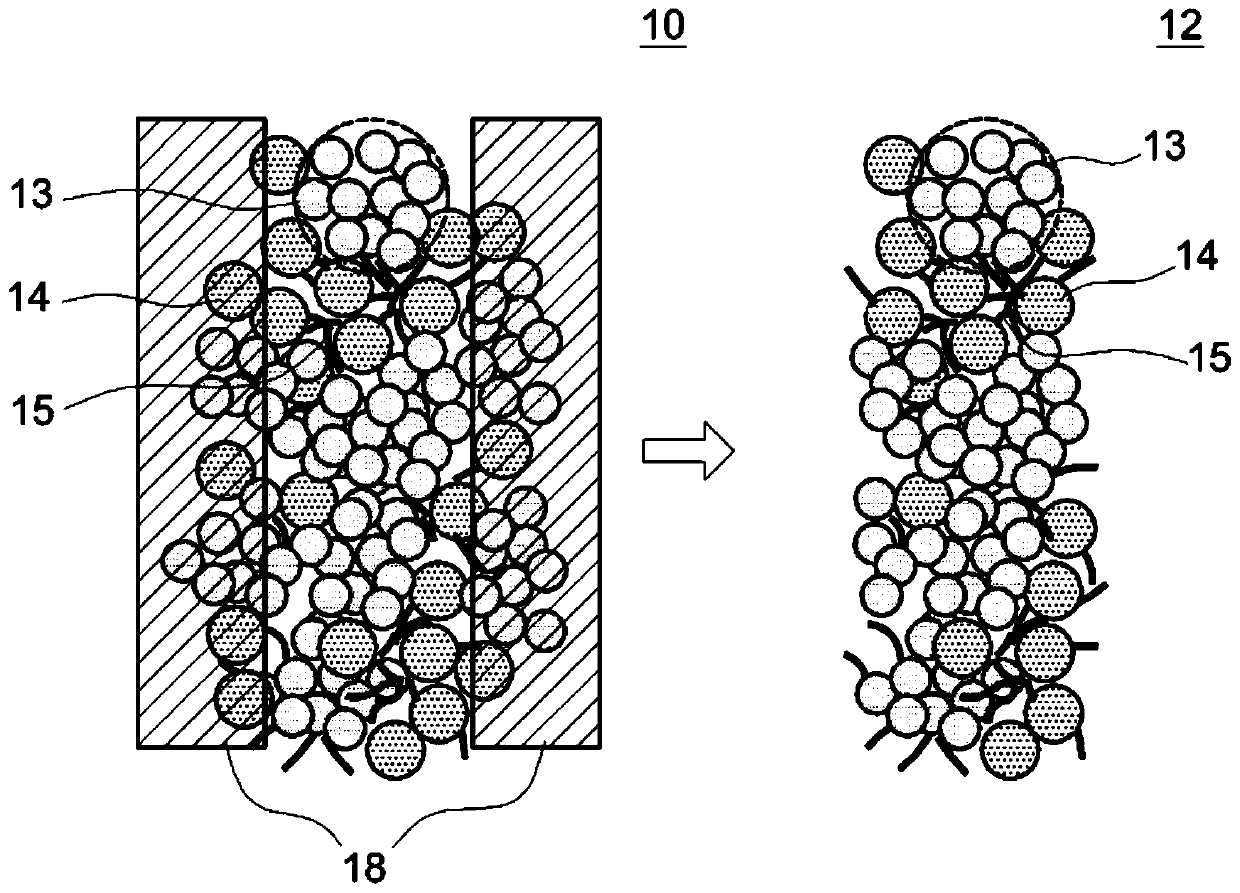

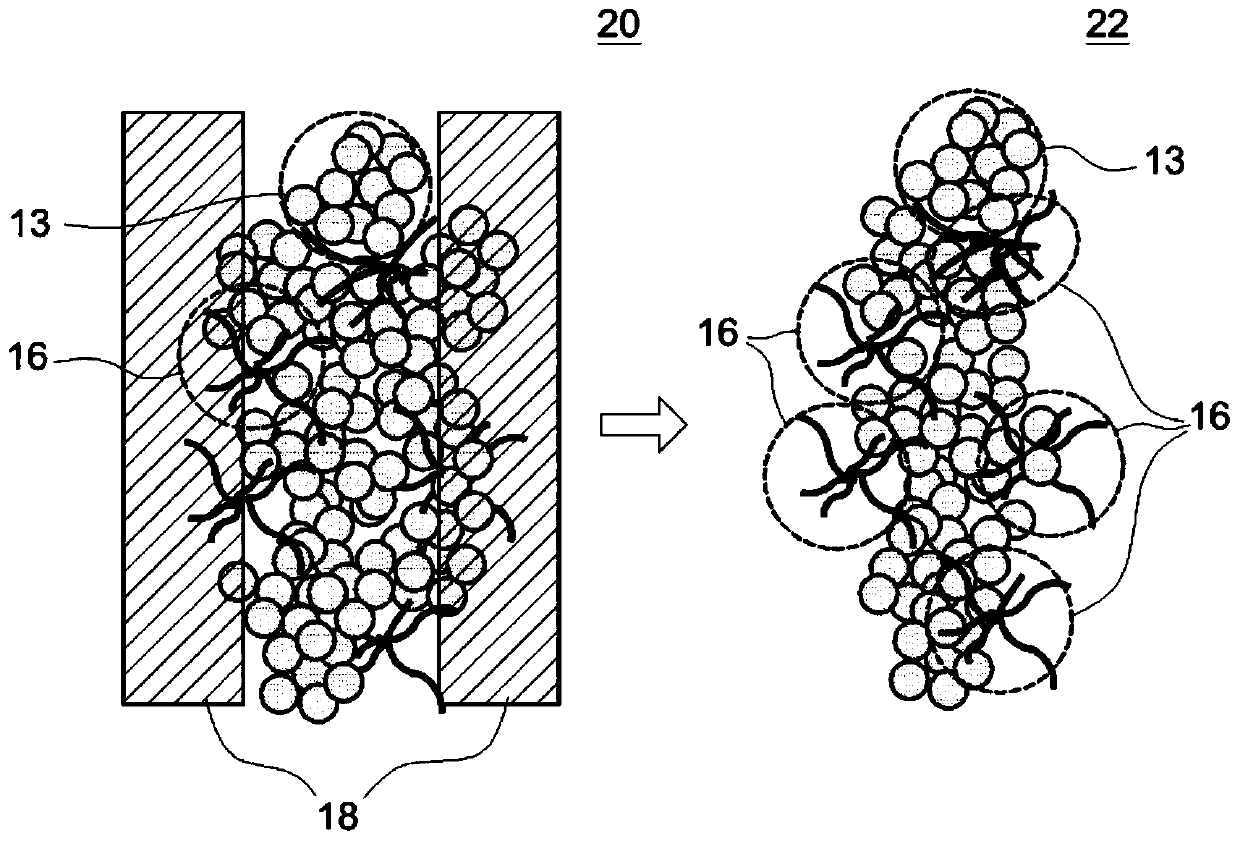

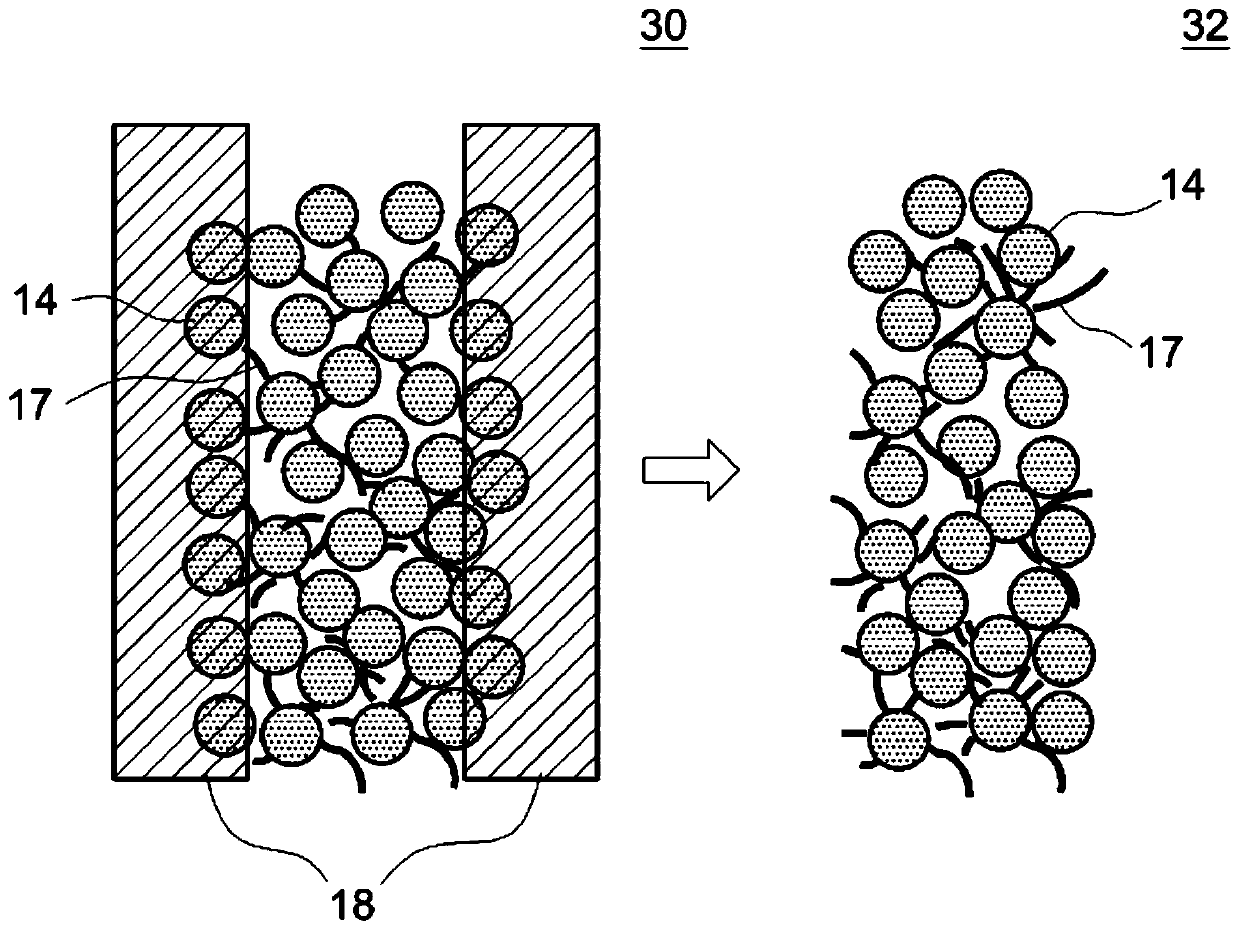

A laminated body of the present invention includes a resin layer in which a core portion composed of a fiber base member having a thickness of 25 μm or less is embedded, the resin layer having two surfaces, and the resin layer through which at least one via-hole is adapted to be formed, and a metal layer bonded to at least one of the two surfaces of the resin layer, and the metal layer having at least one opening portion provided so as to correspond to the via-hole to be formed. Further, a method of manufacturing a substrate of the present invention includes preparing the above laminated body, forming the via-hole so as to pass through the resin layer by irradiating a laser beam onto the resin layer, and removing the metal layer from the resin layer after the via-hole is formed. Further, a substrate of the present invention is manufactured by using the above method. Furthermore, a semiconductor device of the present invention includes the above substrate, and a semiconductor element mounted on the substrate.

Owner:SUMITOMO BAKELITE CO LTD

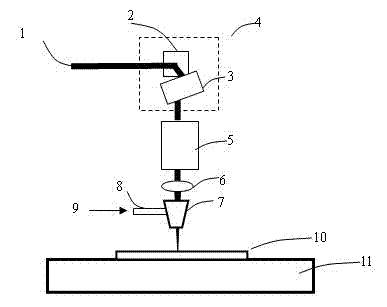

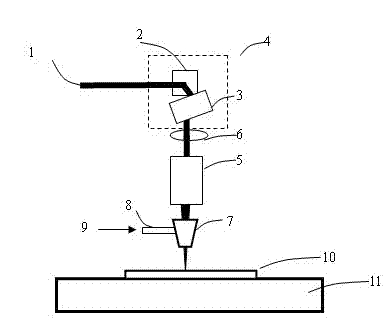

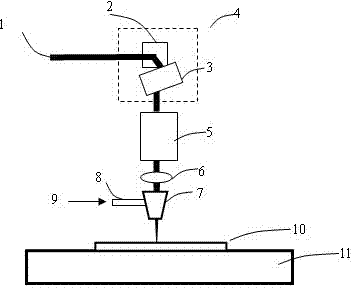

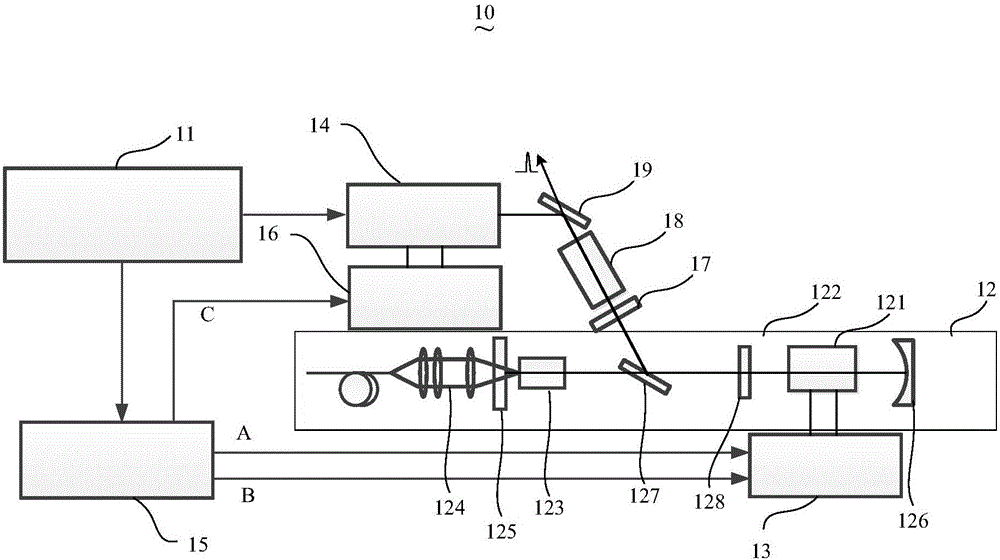

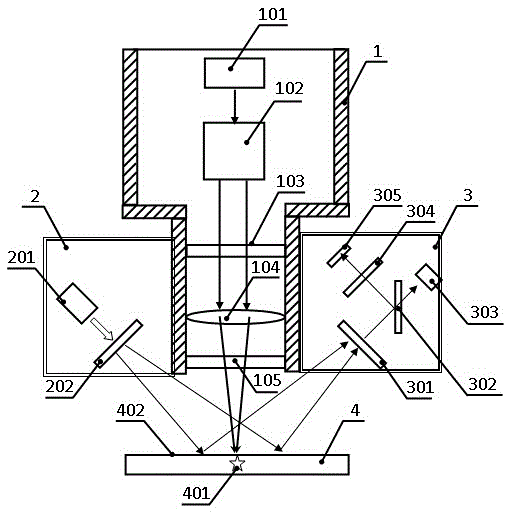

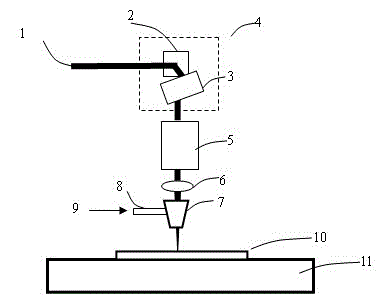

Multifunctional laser processing head

ActiveCN102653030ALow costImprove efficiencyLaser beam welding apparatusLaser processingSpray nozzle

The invention discloses a multifunctional laser processing head. The processing head is formed by combining a scanning galvanometer type laser processing head and a spray nozzle type laser processing head into a closed structure through a connecting piece, and when the multifunctional laser processing head works, a laser beam can enter into the scanning galvanometer type laser processing head, be projected to the spray nozzle type laser processing head via the scanning galvanometer type laser processing head and be further converged on the surface of a workpiece on a two-dimensional worktable. The connecting piece can adopt a connecting cylinder and is positioned between a two-dimensional all-trans scanning galvanometer and a convergent lens or positioned between the convergent lens and a coaxial processing spray nozzle. The multifunctional laser processing head disclosed by the invention can overcome the defects of the existing two laser processing heads and fully utilize the advantages of the two laser processing heads. The invention provides the multifunctional laser processing head, which can realize more than two laser processing ways, reduce cost, improve efficiency and further enhance laser processing capability.

Owner:武汉飞能达激光技术有限公司

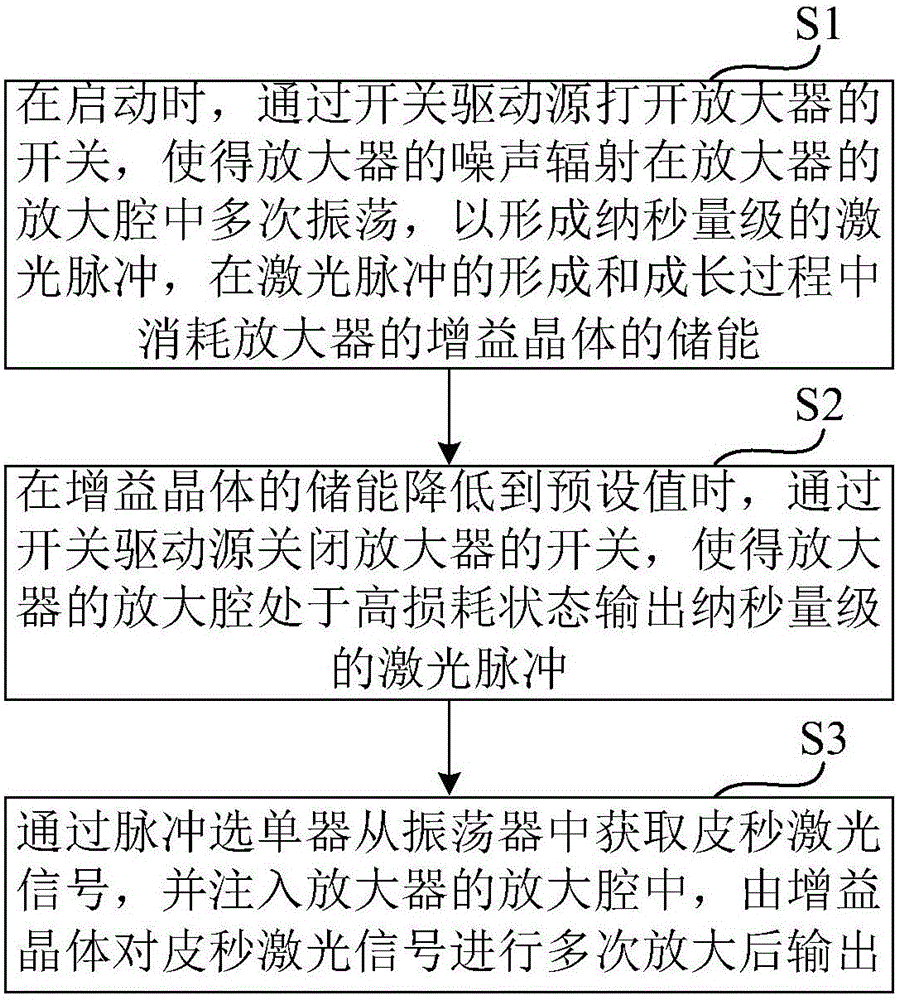

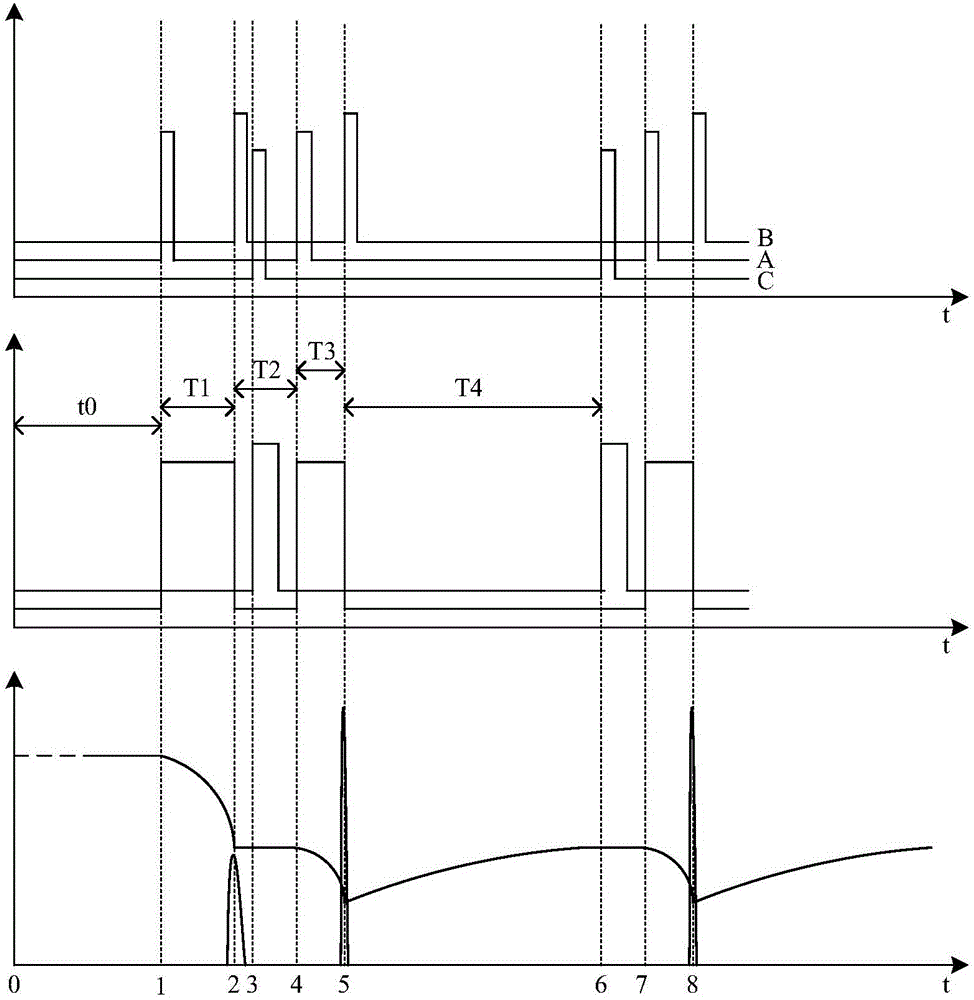

Picosecond laser device and method for inhibiting first pulse in picosecond laser device

InactiveCN105762633AExtended service lifeSuppress energyLaser detailsNanosecond laser pulsePicosecond laser

The invention discloses a picosecond laser device and a method for inhibiting a first pulse in the picosecond laser device. The method comprises the steps that a switch of an amplifier is turned on through a switch driving source during start to oscillate noise radiation of the amplifier in an amplification cavity of the amplifier for multiple times so as to form nanosecond laser pulses, and stored energy of a gain transistor of the amplifier is consumed in the forming and growing process of the laser pulses. When the stored energy of the gain transistor is reduced to a preset value, the switch of an amplifier is turned off through the switch driving source to make the amplification cavity of the amplifier output nanosecond-order laser pulses be in a high-loss state. A picosecond laser signal is obtained from an oscillator through a pulse menu device and is injected into the amplification cavity of the amplifier, and the gain transistor conducts multi-time amplification on the picosecond laser signal and outputs the signal. In the mode, by the adoption of the picosecond laser device and the method, first pulse energy of picosecond laser signals can be inhibited, the service life of optical components and devices can be prolonged, and a laser processing effect can be improved.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

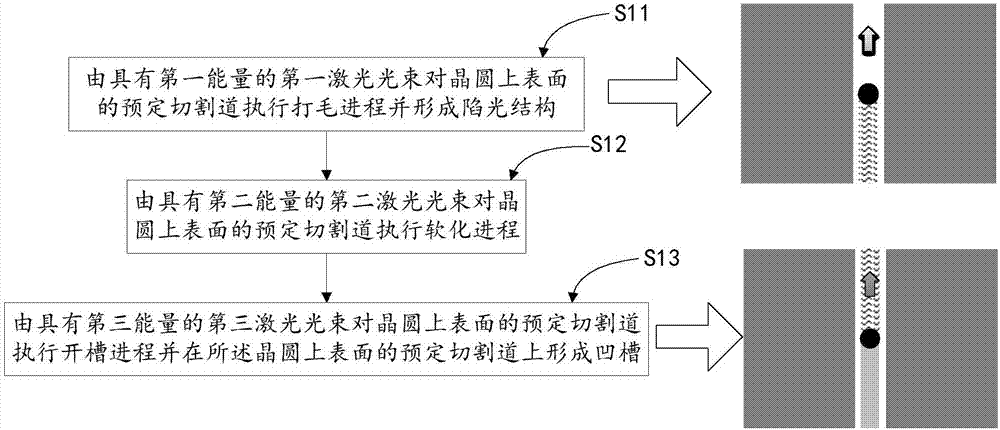

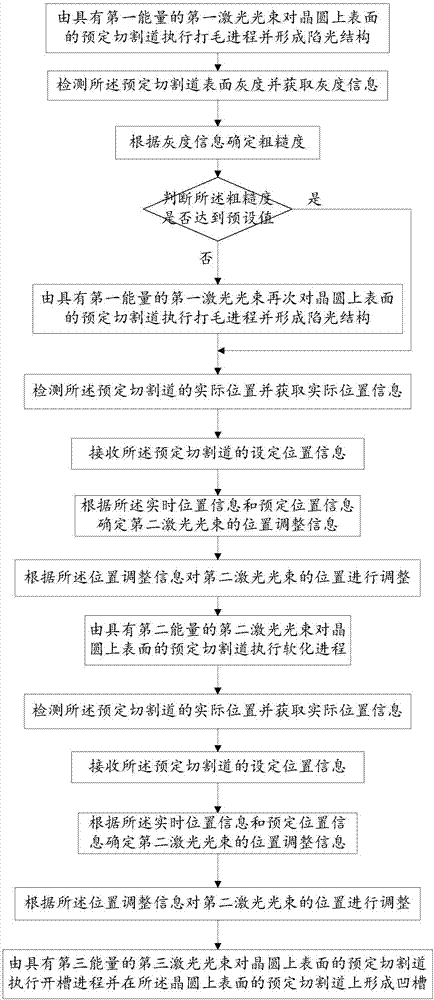

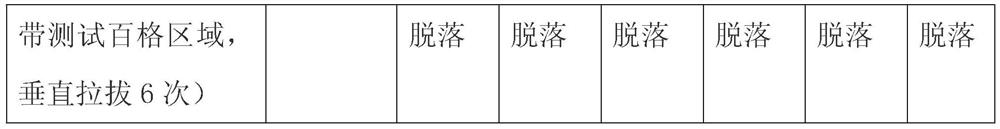

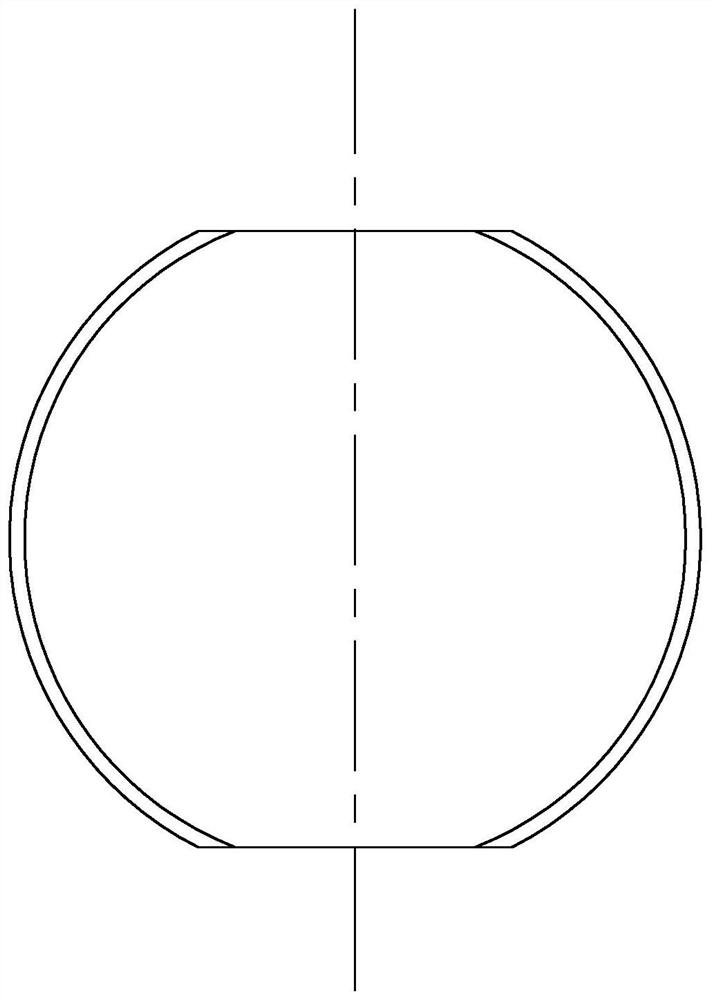

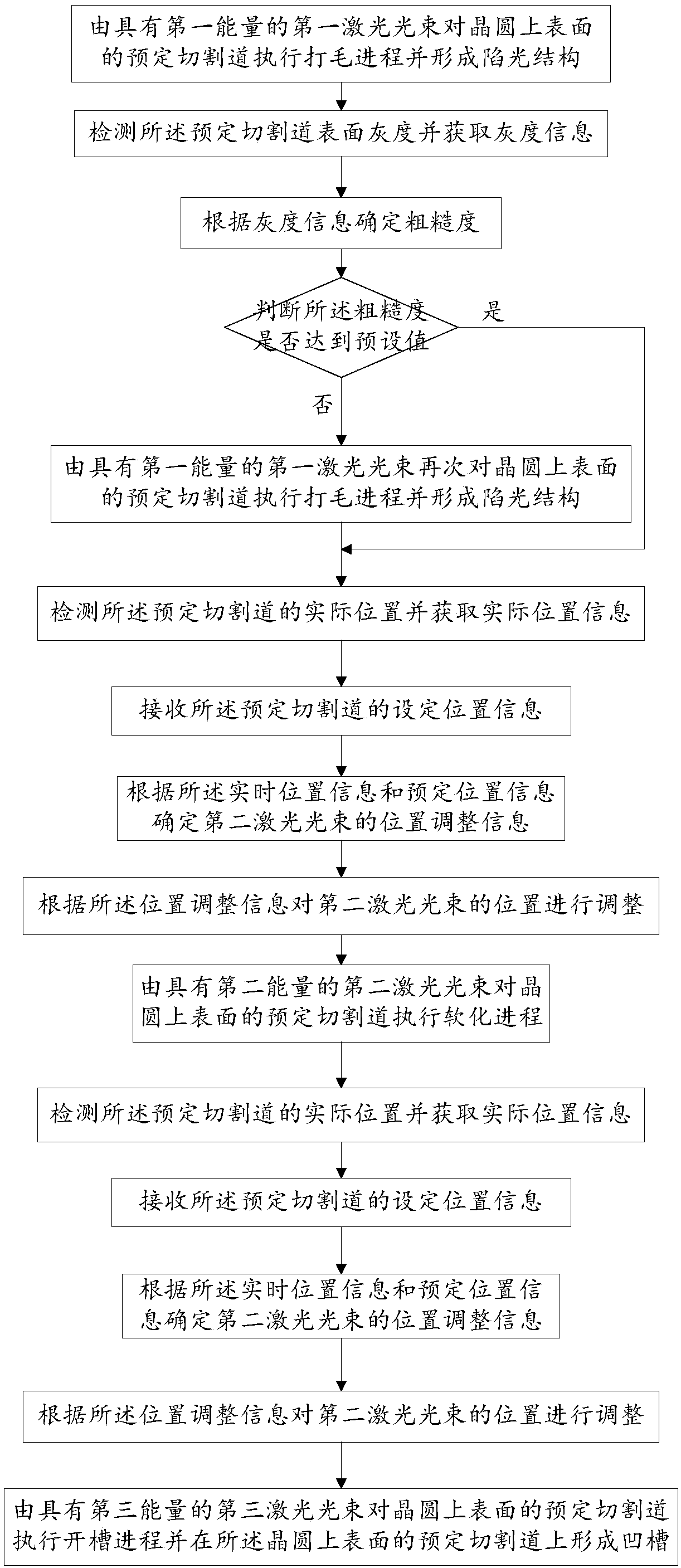

Laser machining method and device for wafer

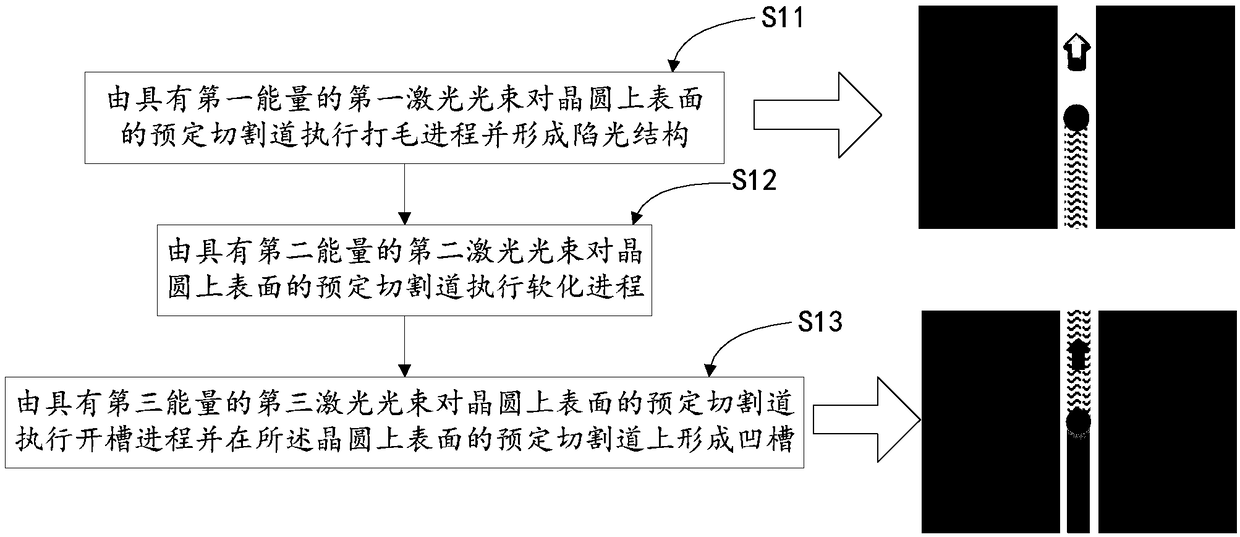

ActiveCN107214419AAvoid damageHigh control precisionMetal working apparatusLaser beam welding apparatusLaser processingHigh energy

The invention provides a laser machining method and device for a wafer. The method comprises that at least two laser beams having different energy distribution respectively execute a hacking process and a grooving process on a predetermined cutting path on the upper surface of the wafer in sequence and are used for forming a groove in the predetermined cutting path on the upper surface of the wafer. The predetermined cutting path on the upper surface of the wafer can be hacked by the laser beams with lower energy, the surface of the predetermined cutting path is roughened to improve a light absorptivity, which is convenient for preparation for a subsequent machining process, and the wafer is prevented from being damaged by stripping of a Low-K material caused by a fact that a Low-K layer on the surface of the wafer is machined by adopting the laser beams with over high energy; and meanwhile, the control precision on the energy of the laser beams in a subsequent machining process is higher, and further a laser machining effect of the upper surface of the wafer is improved.

Owner:北京中科镭特电子有限公司

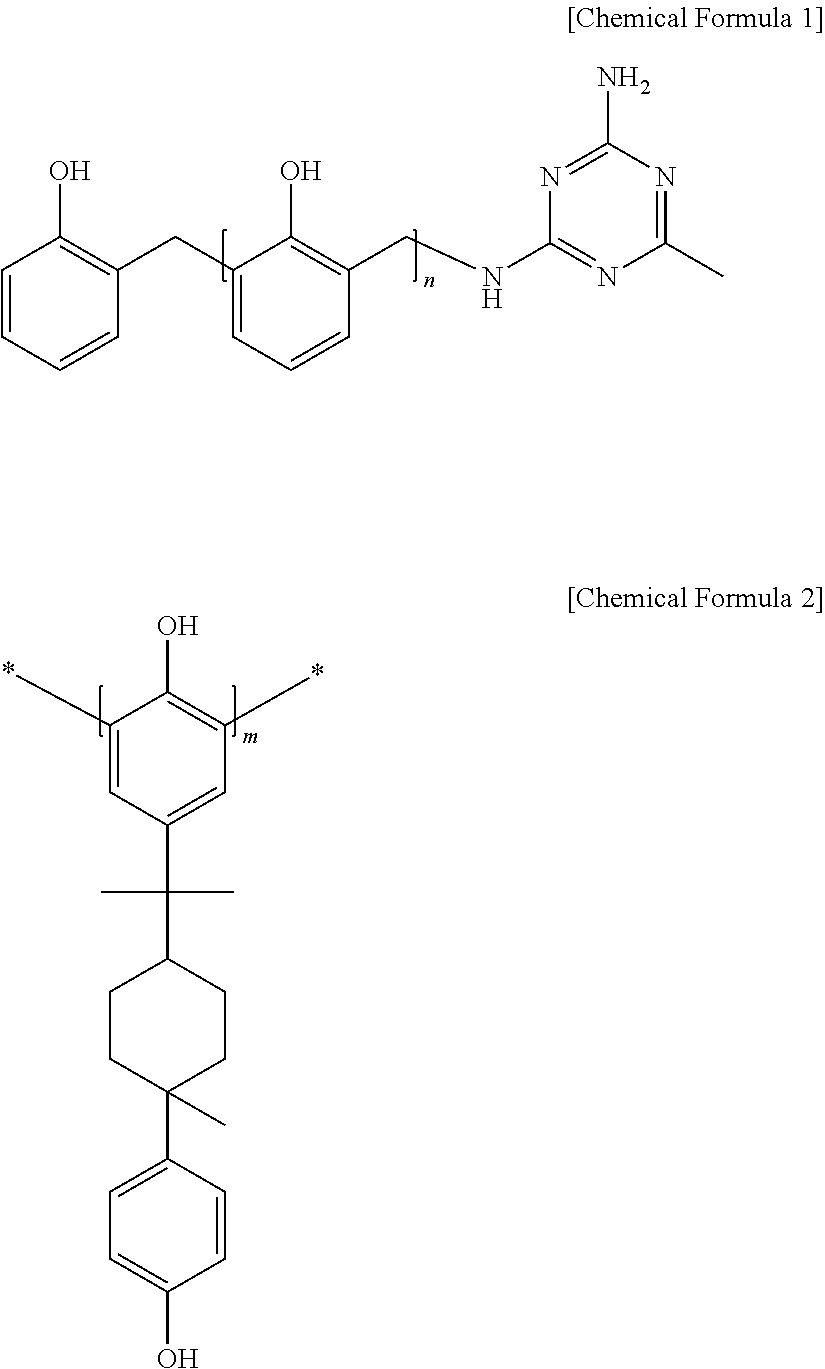

Resin composition and multilayer resin film employing the same

InactiveUS20110003914A1Improve the effect of laser processingPromote absorptionLight absorption dielectricsPrinted circuit manufactureUltravioletUv absorber

A resin composition is provided which allows improvement of the ultraviolet laser processability of the resin and can be not only used as an electronic material for an insulating film of a build-up board and the like but also used to form a circuit board whose electrical insulating property does not deteriorate. A multilayer resin film employing the resin composition is provided. A resin composition is provided which contains a thermosetting resin (A), a curing agent (B), a silica (C), an ultraviolet absorber (D), and a solvent (E) and in which: the content of the ultraviolet absorber (D) is from 0.5 to 50 parts by weight per the total amount of the thermosetting resin (A), the curing agent (B), and the ultraviolet absorber (D); and the blending amount of the solvent (E) is from 20 to 500 parts by weight per 100 parts by weight of the total amount of the thermosetting resin (A) and the curing agent (B). A multilayer resin film is provided in which the resin composition is laminated on a base material so as to be in a sheet shape and in which: the sheet-shaped resin composition on the base material is dried; and the content of the solvent is from 0.01 to 5 parts by weight with respect to the entire resin composition.

Owner:SEKISUI CHEM CO LTD

Copper foil for printed-wiring board

InactiveUS7037597B2Improve the effect of laser processingEnhanced advantageInsulating substrate metal adhesion improvementLight absorption dielectricsAlloyCopper foil

It is an object of the present invention to provide a surface-treated copper foil wherein a surface layer which is situated on a side being not bonded to a resin in a copper foil for a printed-wiring board and on which a copper direct drilling process by carbon dioxide laser is easily applied is prepared with a small amount of a covering material in accordance with a simple manner.In the copper foil used for a direct drilling process by laser of the present invention, 50 to 1000 mg / m2 of a covering layer consisting of iron and tin, or a covering layer made of an alloy prepared from iron, tin, and at least one member selected from the group consisting of nickel, cobalt, zinc, chromium, and phosphorous is provided on at least one side of the copper foil.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

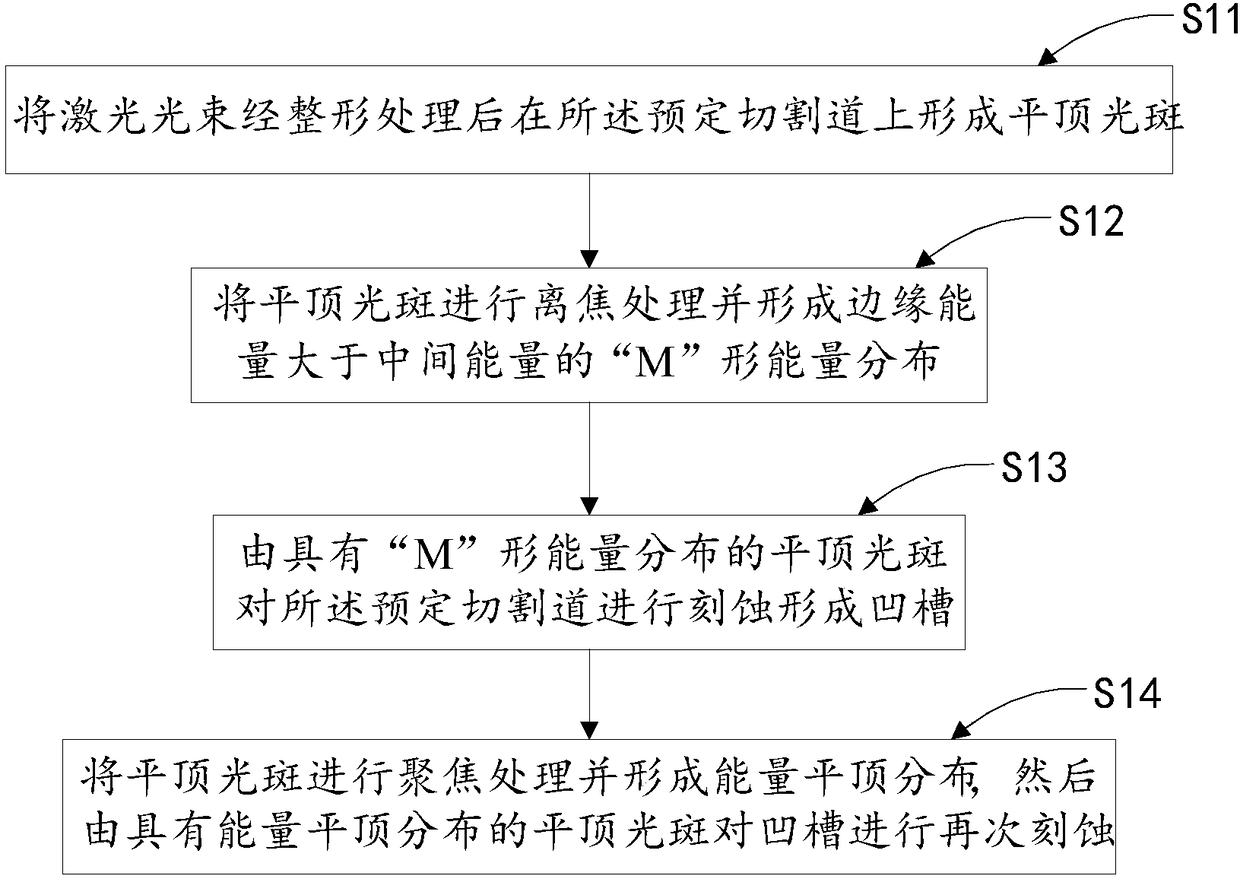

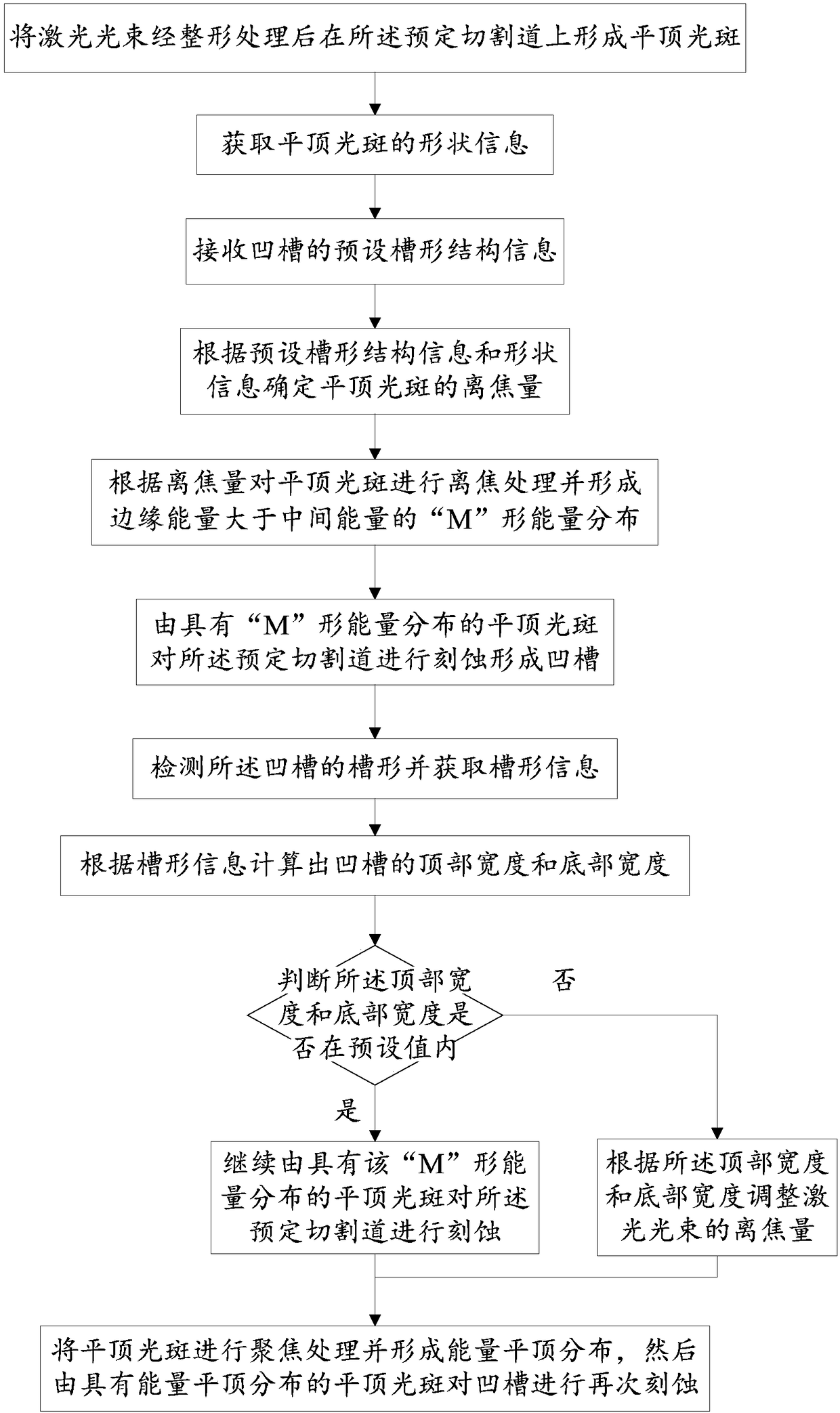

Wafer laser-machining method and device

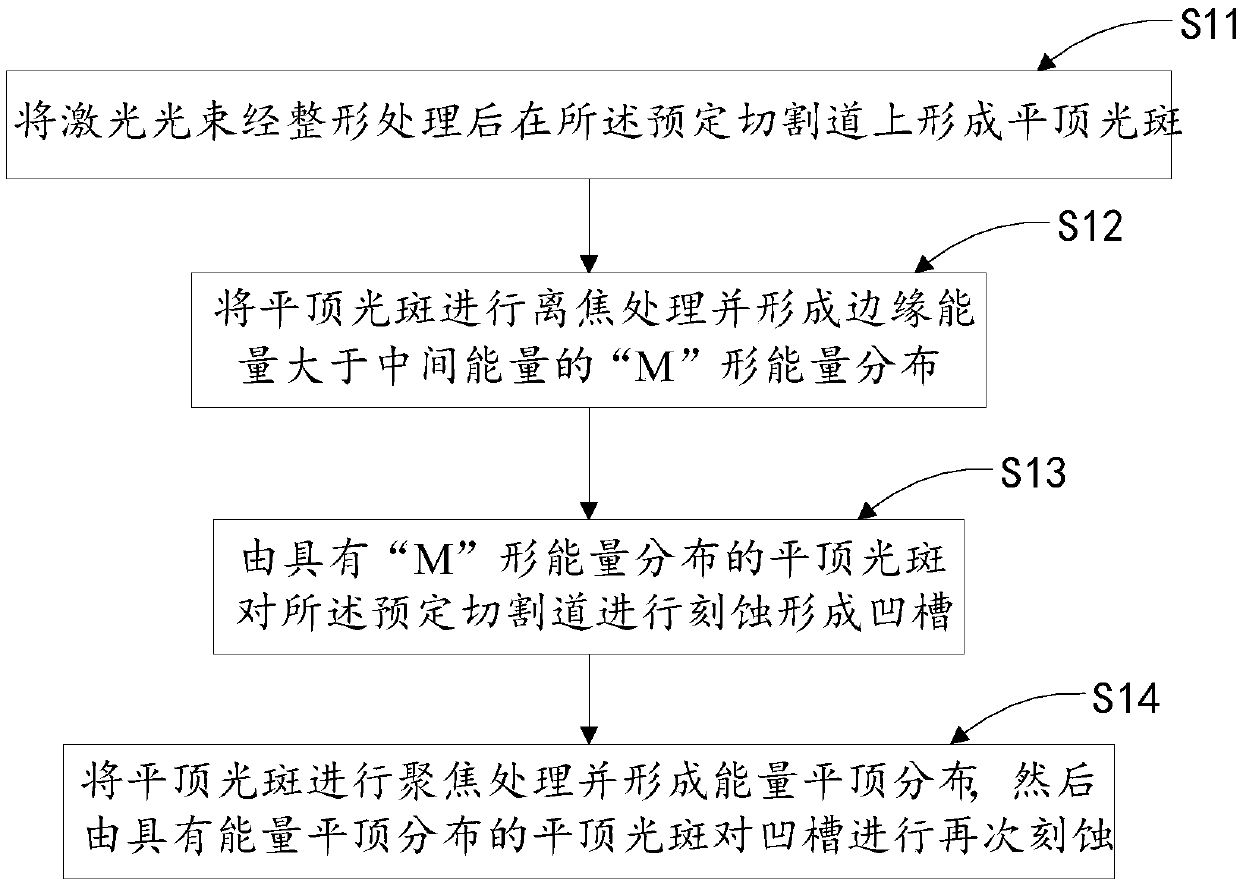

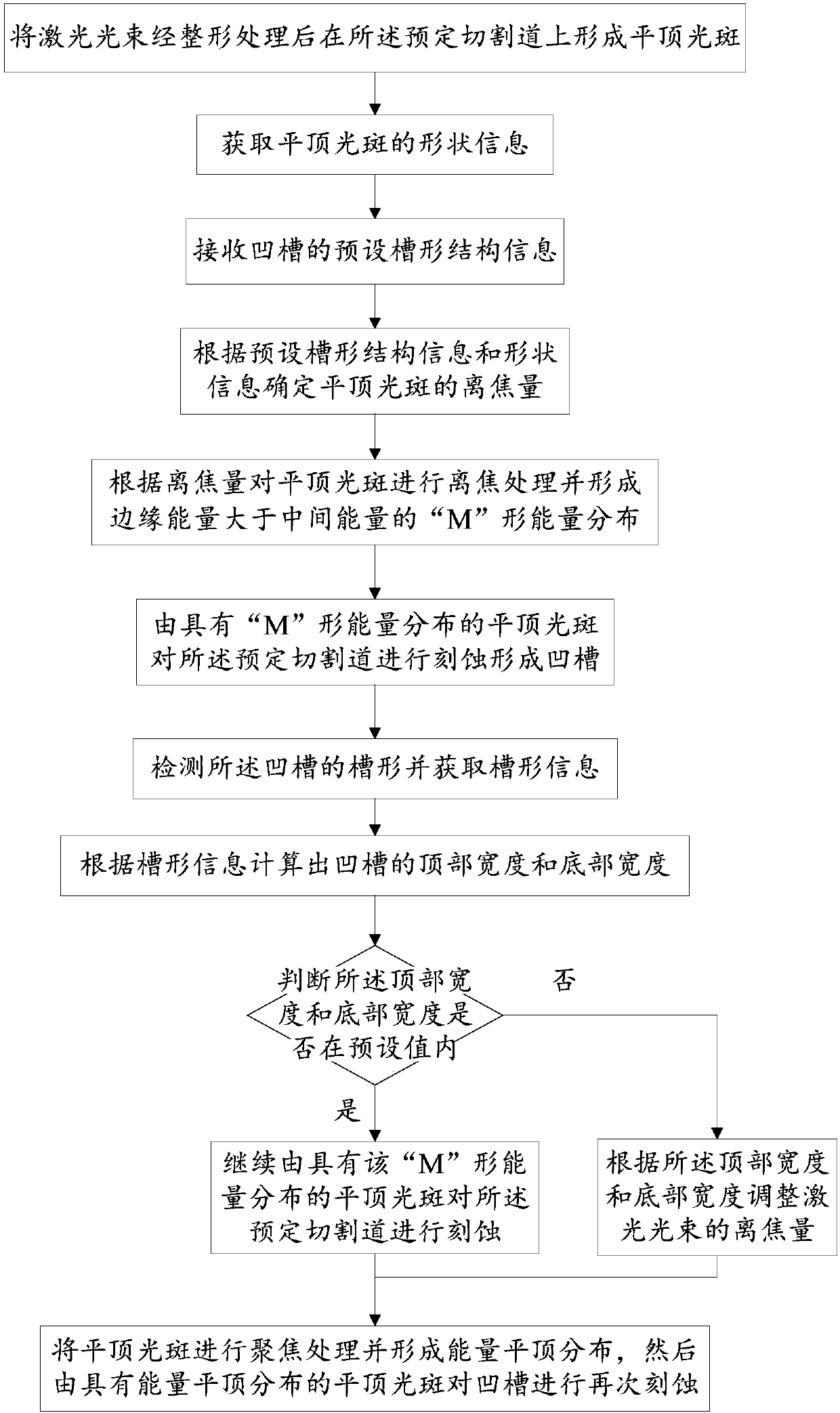

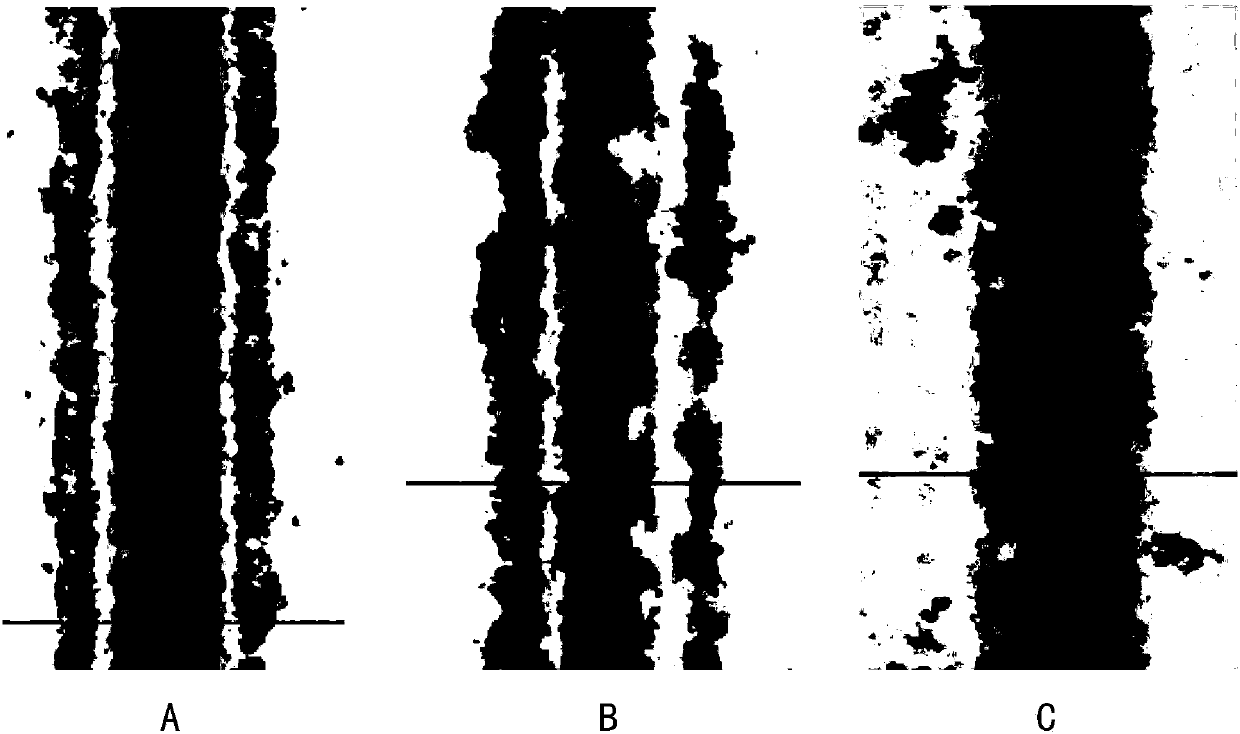

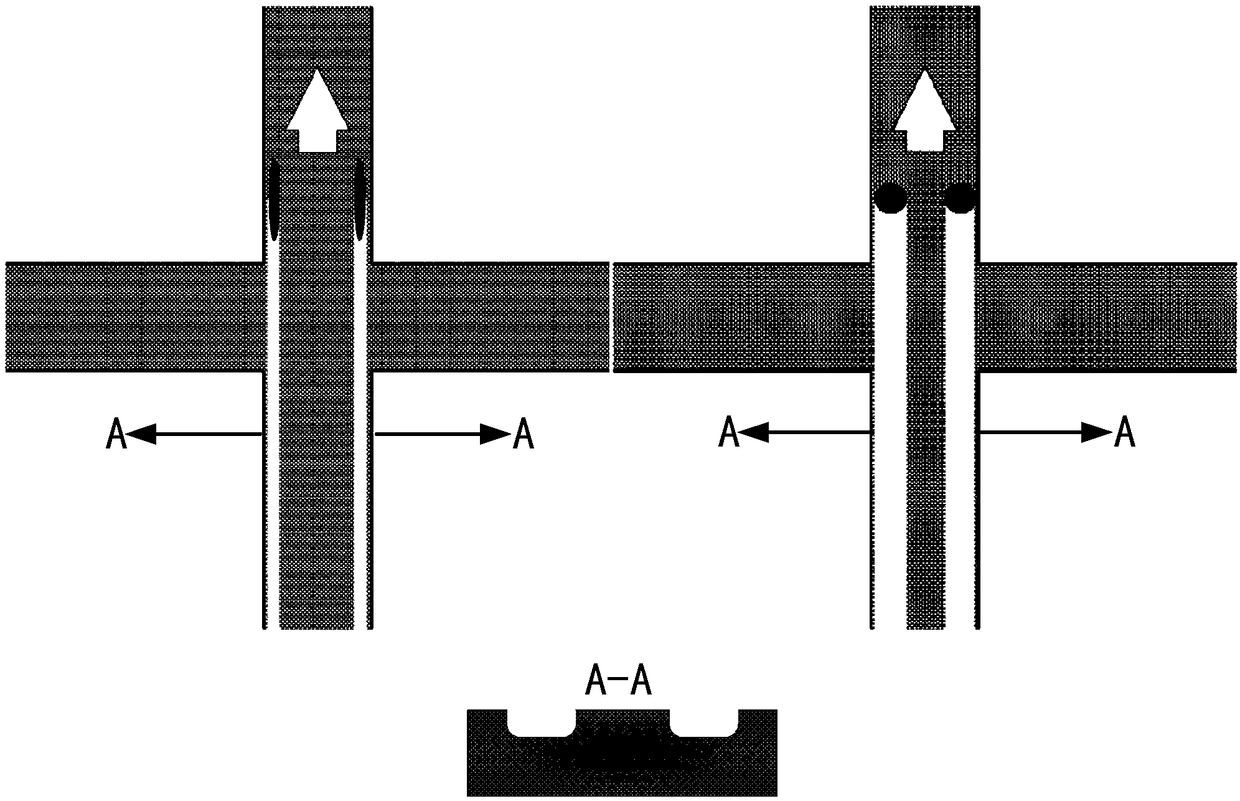

ActiveCN107685196AThe groove wall is steepImprove yield rateLaser beam welding apparatusEngineeringLaser beams

The invention provides a wafer laser-machining method and device. The relative positions of a laser beam and a predetermined cutting path are changed in the direction of the predetermined cutting pathon the upper surface of a wafer, so that a groove is formed in the predetermined cutting path. The method comprises the steps that a flattop light spot is formed on the predetermined cutting path after the laser beam is subjected to shape correction treatment; the flattop light spot is subjected to defocusing treatment, and M-shaped energy distribution with the edge energy greater than the intermediate energy is formed; the flattop light spot with the M-shaped energy distribution is used for etching the predetermined cutting path, so that the groove is formed; and the flattop light spot is subjected to defocusing treatment, energy flattop distribution is formed, and then the flattop light spot with the energy flattop distribution is used for etching the groove again. According to the wafer laser-machining method and device, the wafer can be etched through the flattop light spot with the different energy distribution forms in sequence, the groove bottom of the groove is flatter, the groove wall is steeper, the groove shape quality of the groove is improved, and subsequent machining requirements and the laser machining yield are guaranteed.

Owner:北京中科镭特电子有限公司

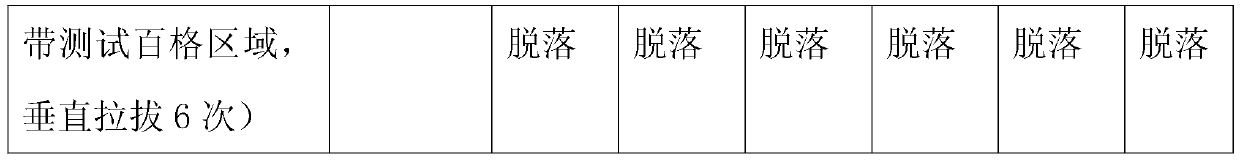

Laser two-dimensional code ear tag modification material special for breeding stock and preparation method

ActiveCN102181146AGood weather resistanceGood compatibilityAnimal husbandryEar tagWeather resistance

The invention discloses a laser two-dimensional code ear tag modification material special for breeding stock. The modification material is characterized by comprising the following materials in part by weight: 97 to 99 parts of polyurethane, 1.5 to 2.5 parts of antimony trioxide, 0.01 to 0.03 part of dispersant and 0.05 to 0.09 part of coupling agent. By using the advantages of the thermoplasticpolyurethane such as oil resistance, toughness, abrasion resistance, ageing resistance and the like and adding a photo-oxidation stabilizing auxiliary agent, the weather resistance of the material isimproved, and the problems of ageing, brittleness, breakage, drop and the like under the actions of air, sunlight and oxygen after an ear tag is worn for long time are solved; and by adding a modifying material into the polyurethane, the laser processing performance of a thermoplastic polyurethane elastomer is enhanced, and batch production of laser processing on the thermoplastic polyurethane elastomer material is realized. Tested by the applicant, the drop, breakage or fracture rate of the ear tag made of the modification material does not exceed 2 percent when the ear tag is worn by the breeding stock in three years.

Owner:贵阳维隆塑胶有限公司

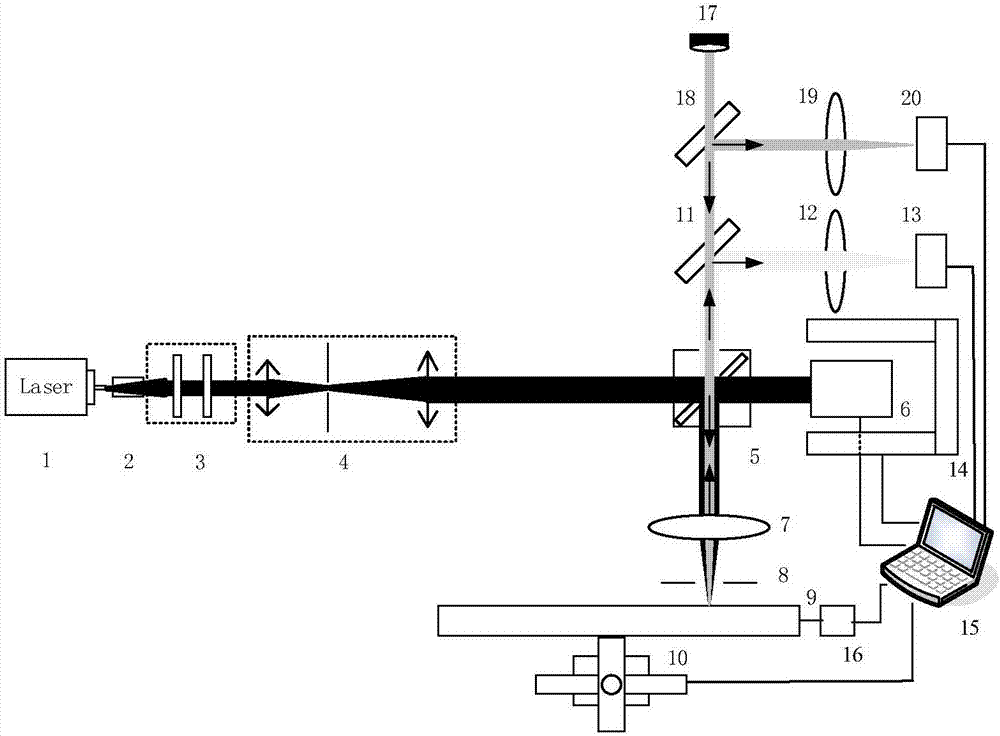

Controllable laser processing device based on wavefront modulation

InactiveCN105537760AImprove laser processing performanceUnleash the full potential of processing characteristicsLaser beam welding apparatusOptical pathWavefront

The invention relates to a controllable laser processing device based on wavefront modulation. The controllable laser processing device based on wavefront modulation comprises a laser processing head, an irradiation module and a photoelectric detection analysis module. The irradiation module and the photoelectric detection analysis module are located in different positions of the laser emitting mechanical edge of the laser processing head. Emitting beams of the irradiation module cover the laser processing working area and peripheral areas of the laser processing head, and light fields inside the emitting beam coverage area of the irradiation module are incident on the photoelectric detection analysis module. A light filed wavefront modulation element is arranged on a laser processing light path, so that shaping is achieved by focusing light spots, the laser processing performance is improved, and an optical material analysis technology and a photoelectric position detection technology are combined. Emitting light of the irradiation module irradiates the laser processing area and the peripheral areas of the laser processing head, material composition information and movement position information inside the irradiated areas are detected by the photoelectric detection analysis module, the phenomenon that a non-processing object enters the laser processing area is avoided, and laser of the laser processing device is safe and controllable.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Special visible ear tag material for livestock, as well as preparation method and ear tag thereof

InactiveCN106957522AGood weather resistanceBrittle fractureAnimal husbandryWeather resistanceThermoplastic polyurethane

The invention provides a special visible ear tag material for livestock, as well as a preparation method and an ear tag thereof. The material is prepared from the following materials in parts by weight: 90-95 parts of modified thermoplastic polyurethane elastomer, 6-8 parts of laser coding agent and 4-6 parts of master-batches, wherein the modified thermoplastic polyurethane elastomer is prepared from TPU, an anti-UV agent and an antibacterial agent. The invention further relates to a method for preparing the ear tag material and an ear tag prepared from the material. The advantages of the thermoplastic polyurethane, including oil resistance, toughness, wear resistance, aging resistance and the like, are utilized, the weather resistance of the material is improved by adding the anti-UV agent, and the technical problem that an livestock ear tag is aged after being worn for a long time, is fragile-fractured and falls can be solved; the technical problem of livestock ear is inflammatory and diseased, since the wearing the ear tag for a long time can be solved by adding the antibacterial agent; and the technical problem that laser labeling cannot be directly carried out on the surface of the thermoplastic polyurethane elastomer can be solved.

Owner:姜有为

Laminated body, method of manufacturing substrate, substrate, and semiconductor device

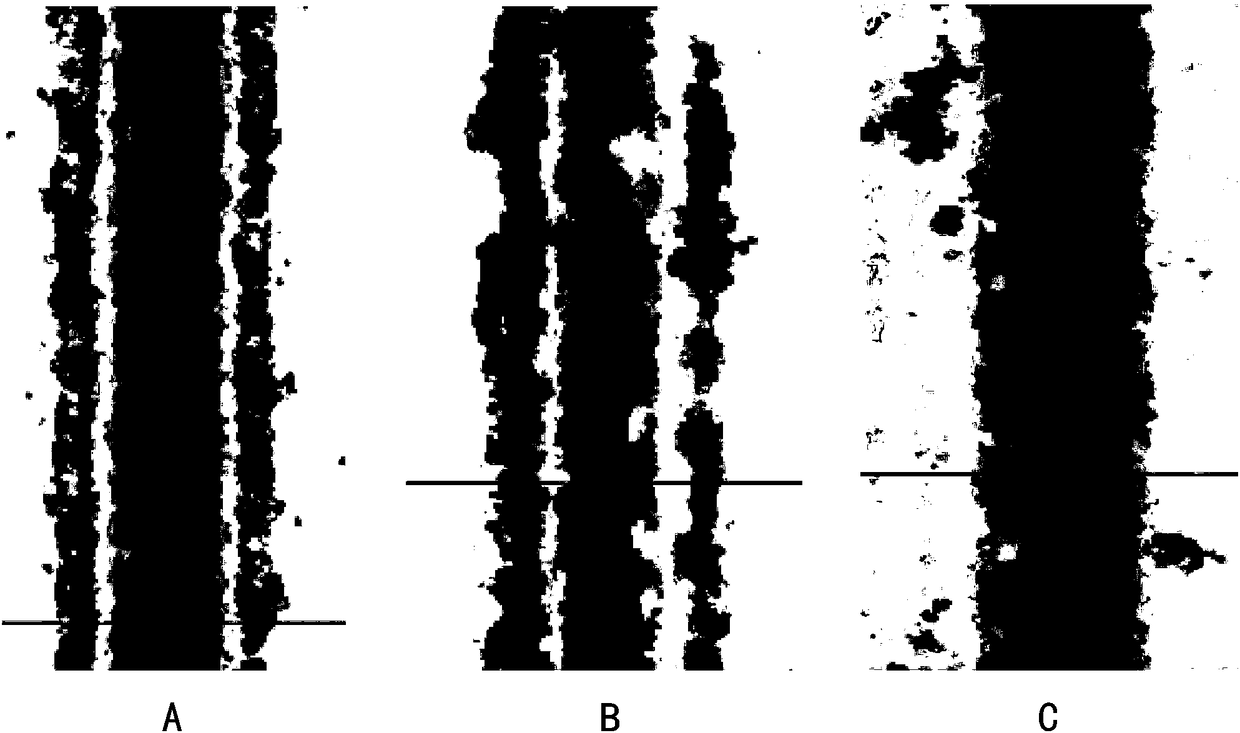

InactiveUS8455765B2Thin thicknessImprove the effect of laser processingSemiconductor/solid-state device detailsSolid-state devicesFiberDevice material

Owner:SUMITOMO BAKELITE CO LTD

Multifunctional laser processing head

ActiveCN102653030BLow costImprove efficiencyLaser beam welding apparatusLaser processingGalvanometer

The invention discloses a multifunctional laser processing head. The processing head is formed by combining a scanning galvanometer type laser processing head and a spray nozzle type laser processing head into a closed structure through a connecting piece, and when the multifunctional laser processing head works, a laser beam can enter into the scanning galvanometer type laser processing head, be projected to the spray nozzle type laser processing head via the scanning galvanometer type laser processing head and be further converged on the surface of a workpiece on a two-dimensional worktable. The connecting piece can adopt a connecting cylinder and is positioned between a two-dimensional all-trans scanning galvanometer and a convergent lens or positioned between the convergent lens and a coaxial processing spray nozzle. The multifunctional laser processing head disclosed by the invention can overcome the defects of the existing two laser processing heads and fully utilize the advantages of the two laser processing heads. The invention provides the multifunctional laser processing head, which can realize more than two laser processing ways, reduce cost, improve efficiency and further enhance laser processing capability.

Owner:武汉飞能达激光技术有限公司

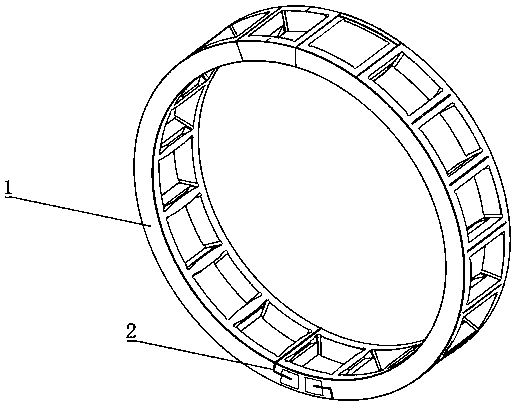

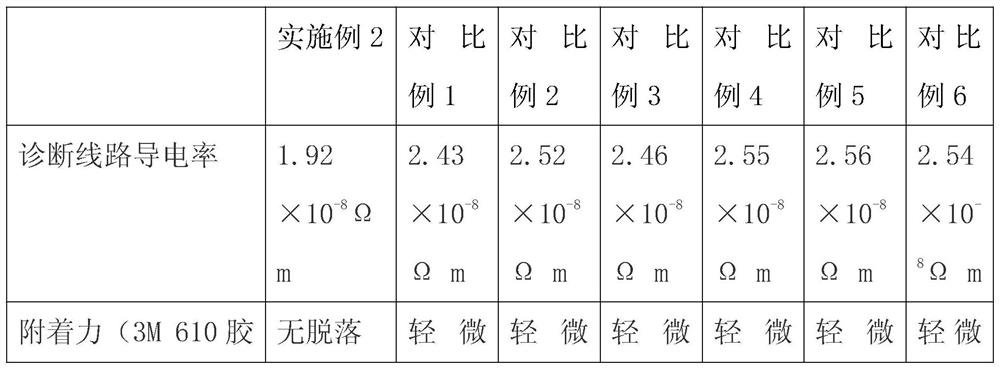

Water-based nano coating material, preparation process of micro-crack diagnosis circuit and application of micro-crack diagnosis circuit

ActiveCN111423812AHigh precisionImprove qualityFireproof paintsLiquid surface applicatorsElectrically conductiveMechanical properties of carbon nanotubes

The invention discloses a water-based nano coating material and a preparation process and application of a micro-crack diagnosis circuit; the self-developed water-based nano coating material capable of being subjected to laser metallization treatment is adopted, and a laser beam moves on the surface of a product so as to activate the surface of the material at a place where a conductive path needsto be arranged. By means of a laser direct patterning + grain refining plating method, a conductive path width of 100 microns or less can be obtained. The invention aims to take out the influence ofother fillers and improve the precision of a laser direct graphical line, so that the laser direct graphical line reaches the preset mechanical property. The added laser direct patterning workpiece issprayed with a water-based nano coating in advance, so that the influence of other fillers on the material processability, the mechanical property and the later laser processability is avoided, and the quality of the workpiece is greatly improved; the prepared coating has good adhesive force, salt fog resistance, high temperature and high humidity resistance and cold and hot impact resistance, and a diagnosis circuit has good adhesive force and conductivity.

Owner:邓文

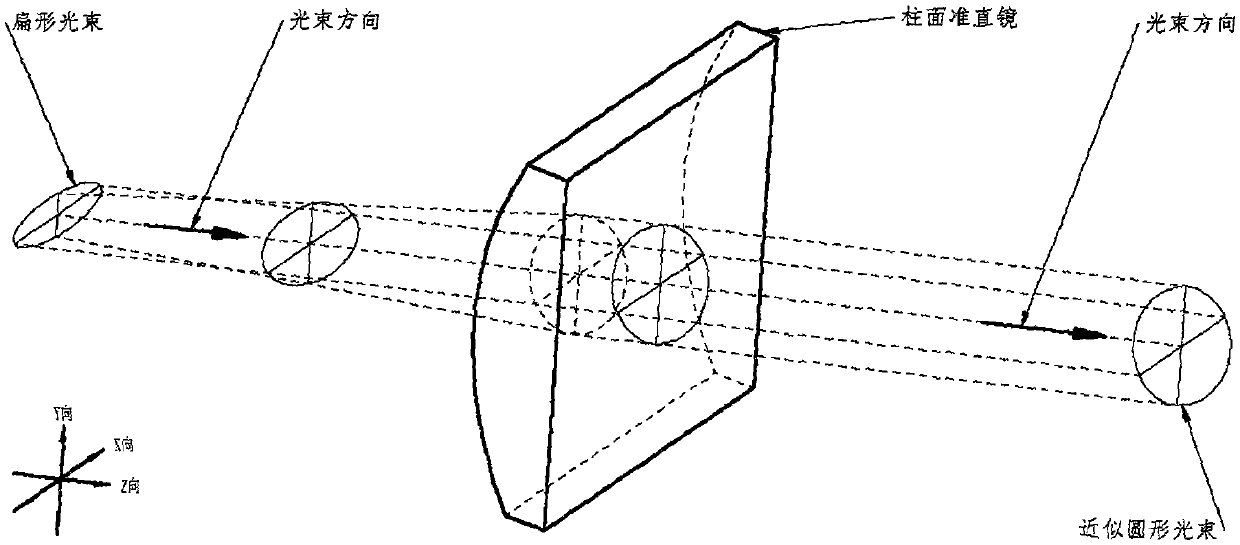

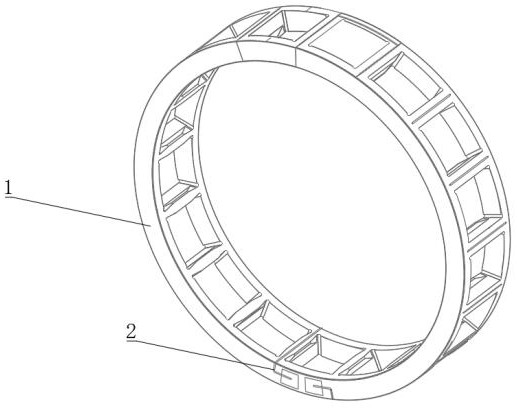

Radio frequency laser with cylindrical surface collimating mirror

InactiveCN105375252AExtended service lifeTake advantage ofLaser constructional detailsOptoelectronicsRadio frequency

The invention provides a radio frequency laser with cylindrical surface collimating mirror, mainly comprising a radio frequency laser, a cylindrical surface collimating mirror and a reflex lens.

Owner:BEIJING RECI LASER TECH

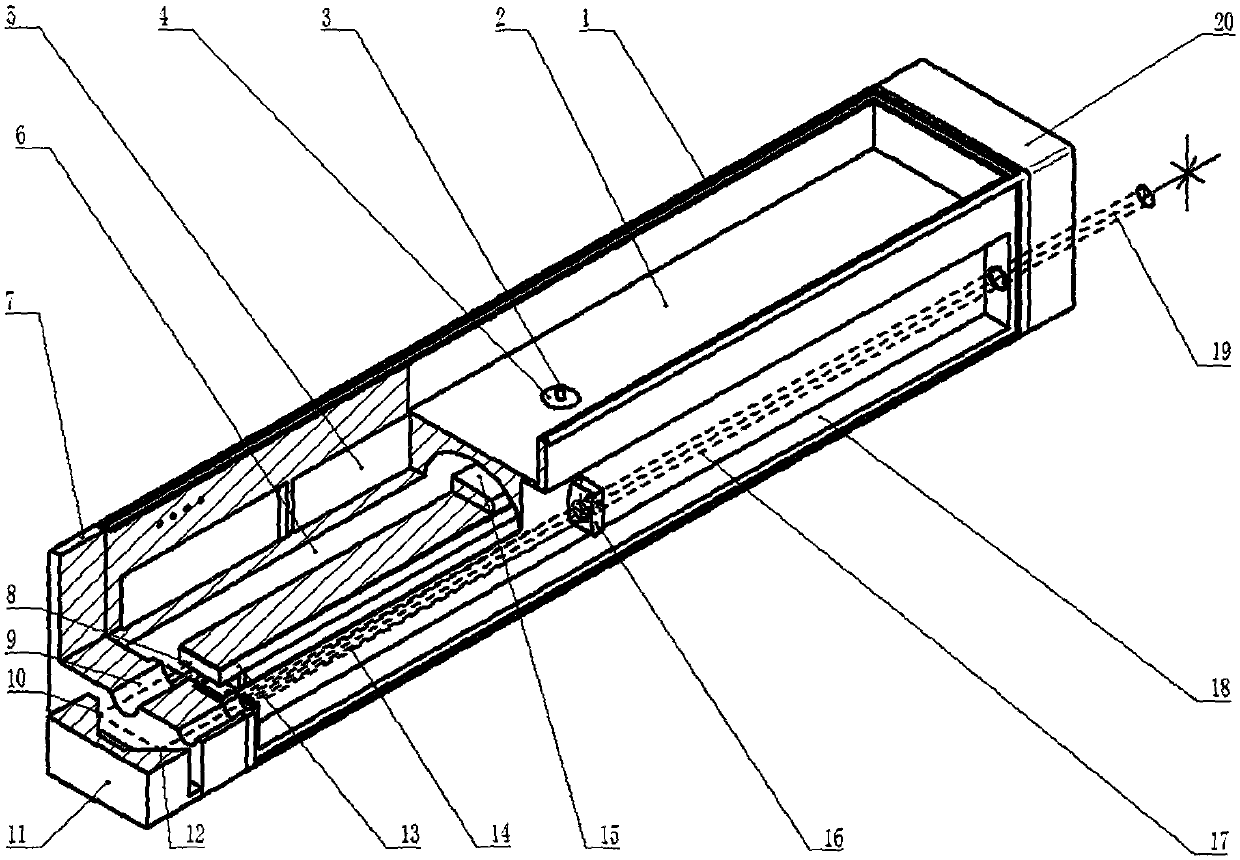

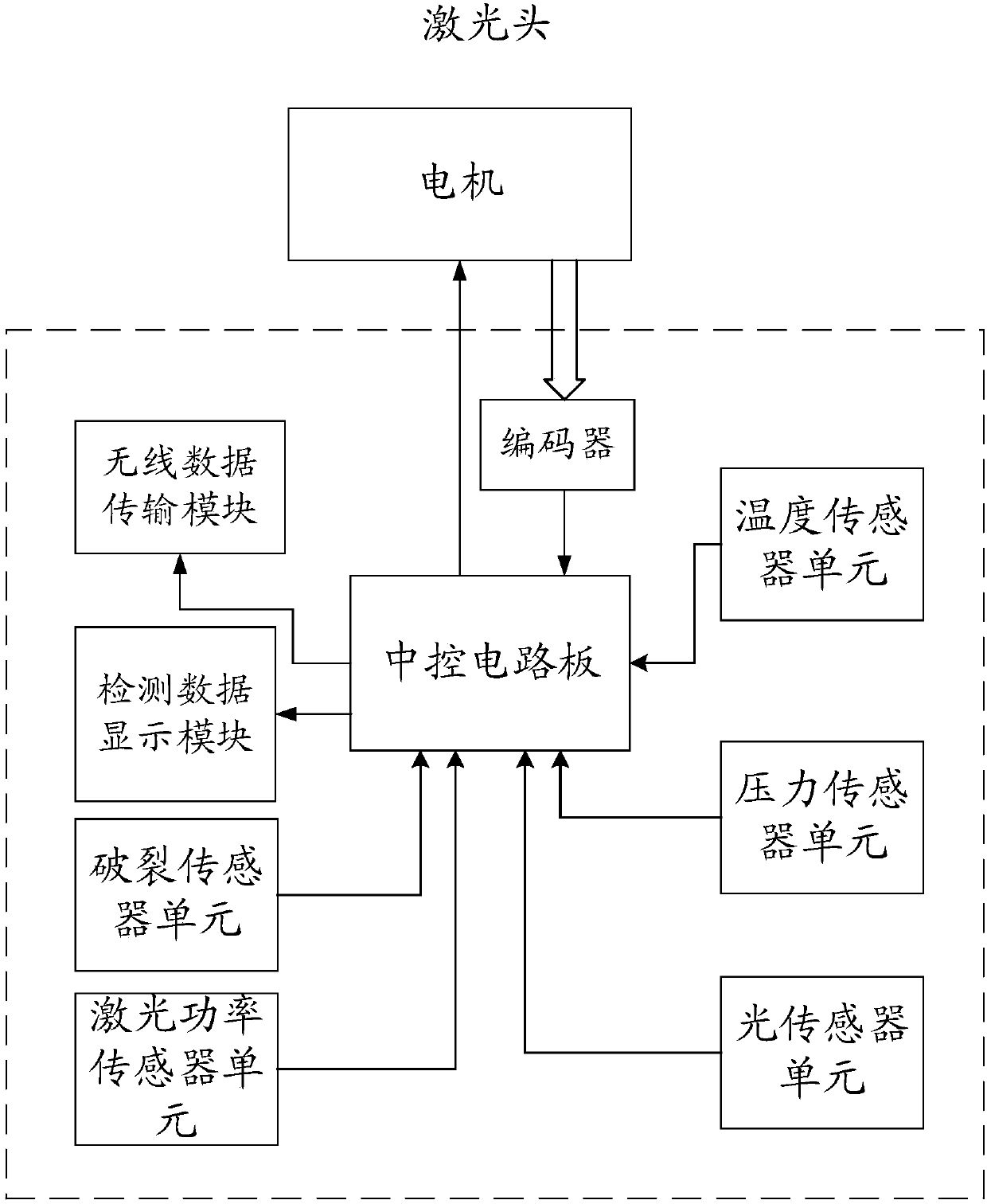

Checkout equipment applied to laser head and corresponding laser head

PendingCN107931873AAdjust in timeEasy to adjustLaser beam welding apparatusComputer hardwareData display

The invention relates to checkout equipment applied to a laser head and the corresponding laser head. The equipment comprises a first data detection module used for detecting all parameters of the laser head and related equipment of the laser head, a detection data display module and a control module connected with the first data detection module and the detection data display module, used for converting all parameters detected by the first data detection module into all parameters capable of being displayed by the detection data display module and used for controlling all modules in the laserhead; and the detection data display module is fixed to the exterior of a shell of the laser head, and the first data detection module and the control module are arranged inside the shell of the laser head. By means of the checkout equipment of the structure and the corresponding laser head, the low laser machining process accuracy caused by the fact that detection on laser state parameters is not in time can be effectively avoided.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

Laser plane machining device

PendingCN110756987AWide range of applicationsImprove the effectLaser beam welding apparatusLaser planeEngineering

The invention discloses a laser plane machining device. The device comprises a supporting assembly, a clamping block, a laser head, a monitoring assembly and a measuring assembly, wherein a workpieceis placed on the supporting assembly, and the clamping block is arranged above the supporting assembly; the laser head is arranged on the clamping block and is located above the workpiece, and an angle is arranged between the laser head and a to-be-machined surface of the workpiece; the monitoring assembly comprises a camera, the camera is arranged on the clamping block, the camera is aligned withthe workpiece, and the central axis of the camera is perpendicular to the to-be-machined surface of the workpiece; and the measuring assembly comprises an optical distance measuring instrument, the optical distance measuring instrument is arranged on the clamping block, and the optical distance measuring instrument is aligned with the workpiece. According to the device, by means of the mode, thelaser can be used for machining the workpiece in the direction inclined to the to-be-machined surface of the workpiece, the device can be suitable for a workpiece with an uneven initial surface, the application range of the device is wide, and the effect of laser machining is improved.

Owner:苏州高意激光科技有限公司

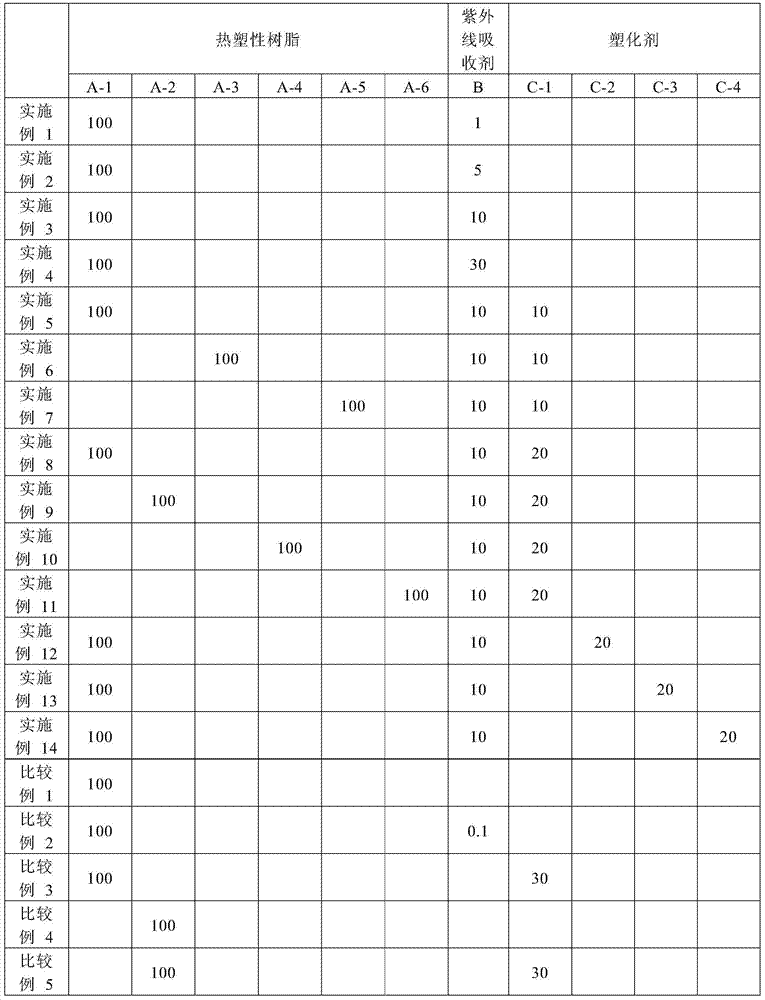

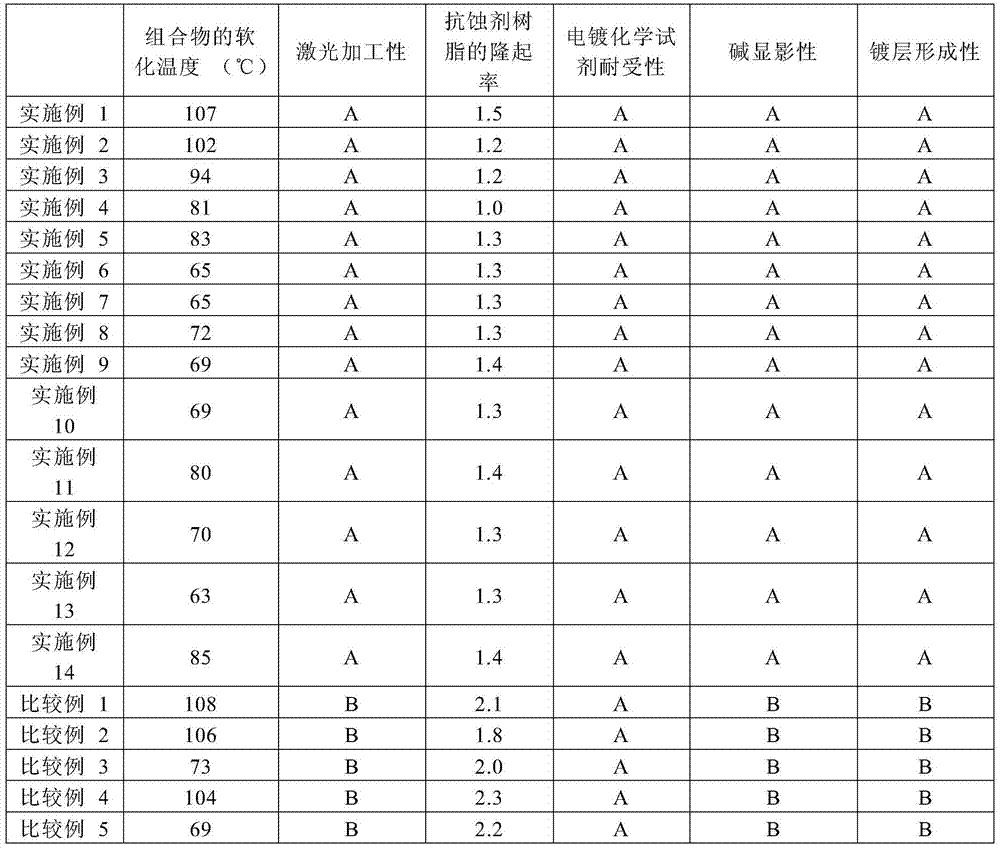

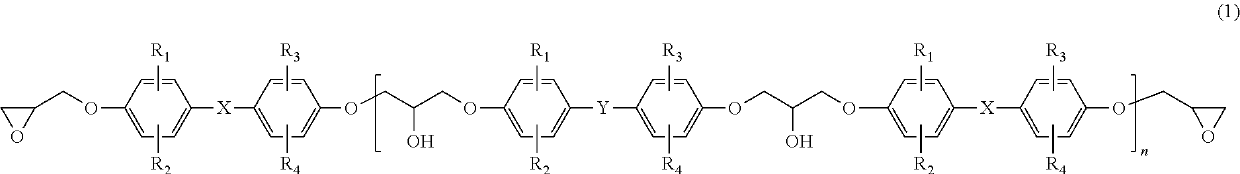

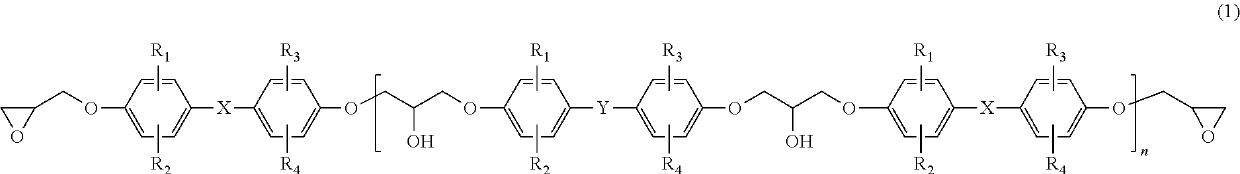

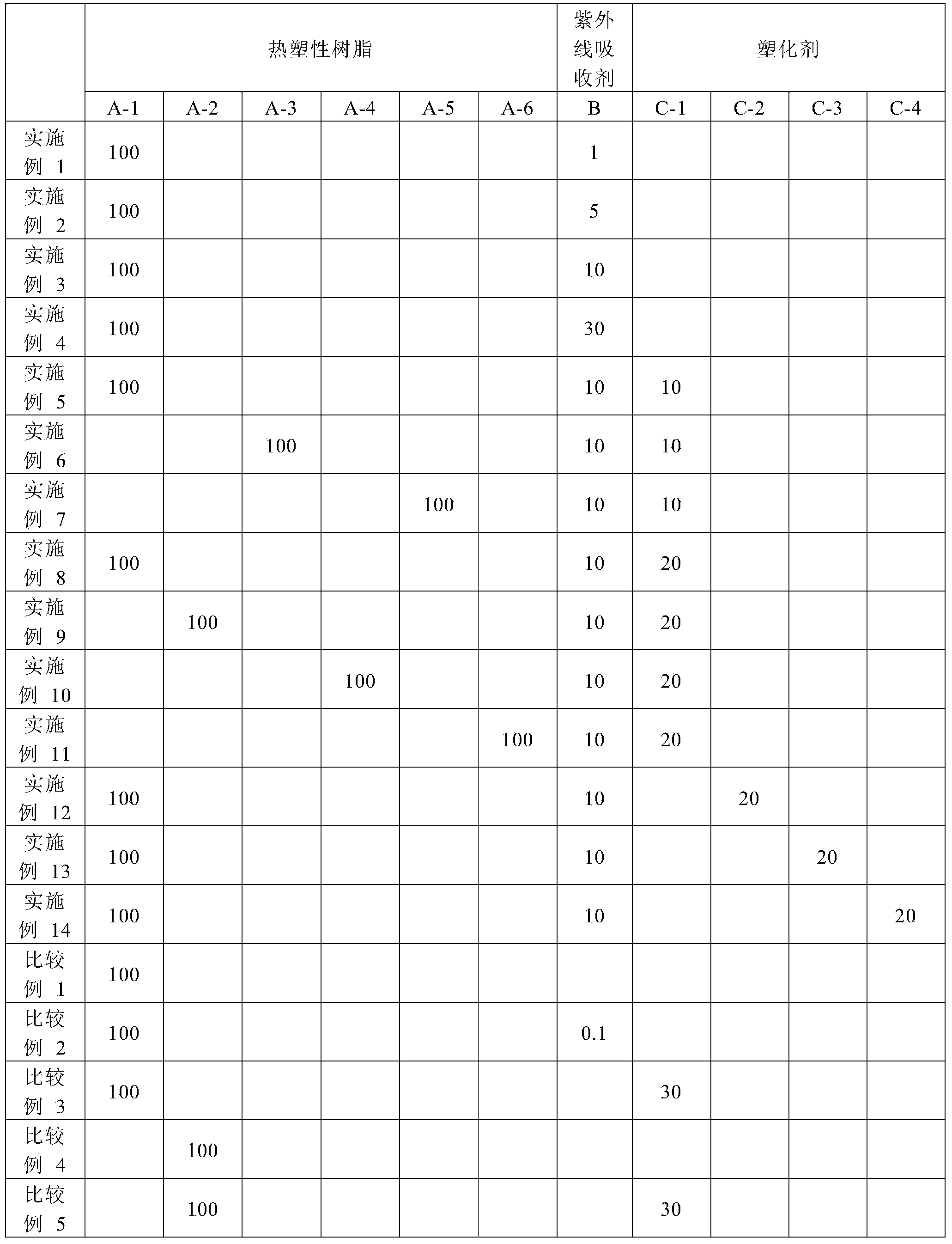

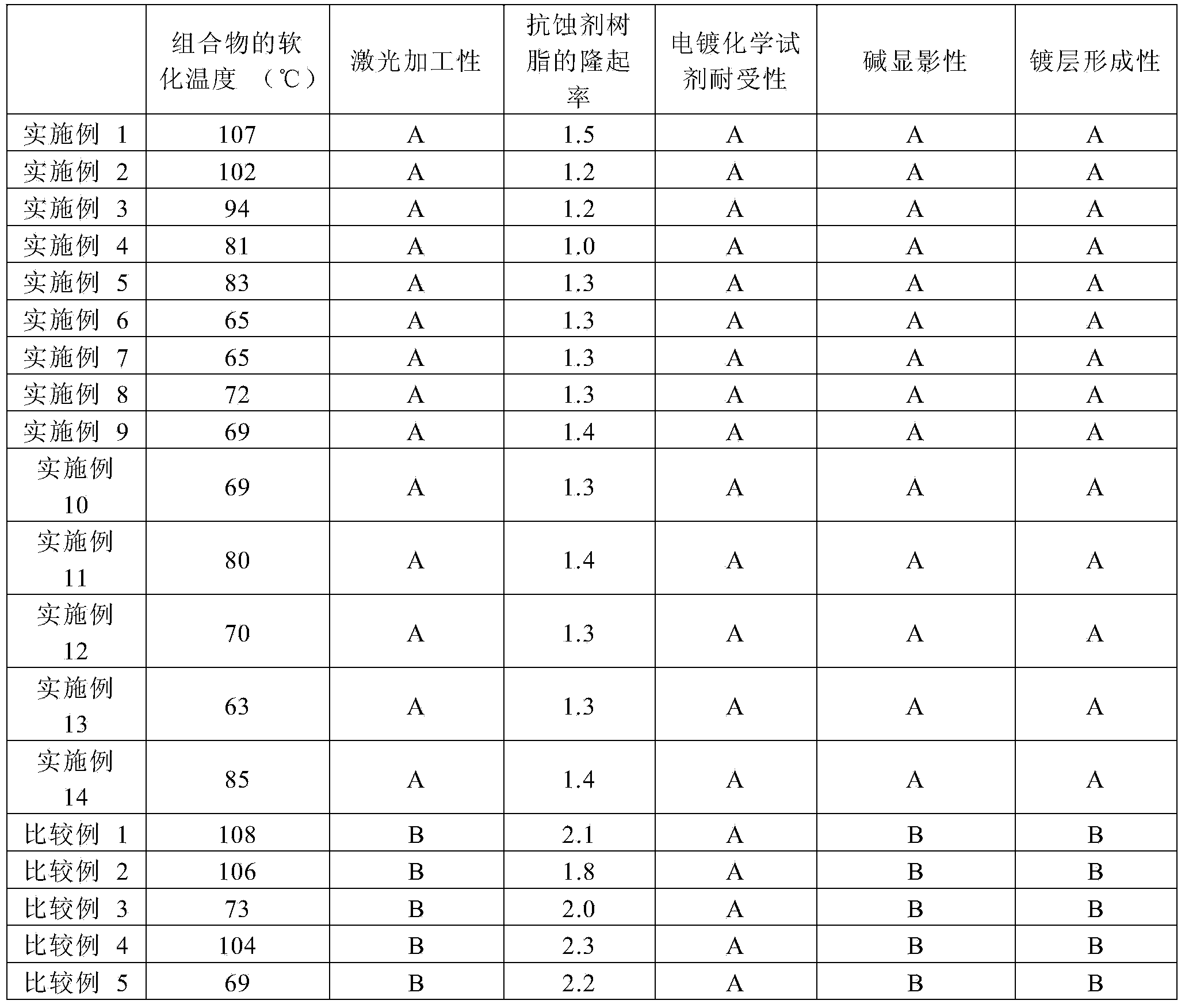

Resin composition for laser processing

ActiveCN104169370BPromote absorptionImprove the effect of laser processingCoatingsCircuit masks compositionResistLaser processing

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Thermosetting electrically conductive paste

ActiveCN106941018AEasy to thermally decomposeGood removal effectNon-conductive material with dispersed conductive materialConductive pasteConductive polymer

To provide a thermosetting electrically conductive paste excellent in laser processability and enabling an electrode having high electrical conductivity to be formed. According to the present invention, the thermosetting electrically conductive paste is provided. The thermosetting electrically conductive paste contains an electrically conductive powder, a thermosetting resin and a curing agent. The electrically conductive powder contains a non-agglomerated electrically conductive powder and an agglomerated electrically conductive powder different from each other in a degree of agglomeration expressed by a ratio (L-D 50 / SEM-D 50) between a number-basis average particle size (SEM-D 50) based on electron microscope observation and a volume-basis average particle size (L-D 50) based on a laser diffraction scattering particle size distribution measurement method. The degree of agglomeration of the non-agglomerated powder is 1.5 or smaller, the degree of agglomeration of the agglomerated powder exceeds 1.5 and is 3 or smaller, the L-D 50 of the agglomerated electrically conductive powder does not exceed L-D 50 of the non-agglomerated electrically conductive powder.

Owner:NORITAKE CO LTD

Preparation process and application of water-based nano-coating materials and micro-crack diagnostic circuits

ActiveCN111423812BHigh precisionImprove qualityFireproof paintsLiquid surface applicatorsLaser processingMaterials processing

The invention discloses a preparation process and application of a water-based nano-coating material, a microcrack diagnostic circuit. The invention adopts a self-developed water-based nano-coating material that can be treated by laser metallization, and moves on the surface of the product through a laser beam The surface of the material is thereby activated where a conductive path is to be provided. With the help of laser direct patterning + fine-grained plating method, a conductive path width of 100 microns or less can be obtained. The purpose of the present invention is to remove the influence of other fillers, improve the accuracy of laser direct patterning lines, and make them reach preset mechanical properties. The added laser direct patterning workpiece is pre-sprayed with water-based nano-coating to avoid other fillers from affecting the material processing performance, mechanical properties and later laser processing performance, which greatly improves the quality of the workpiece; the prepared coating has good attachment Strength, salt spray resistance, high temperature and high humidity resistance and thermal shock resistance, the diagnostic circuit has good adhesion and conductivity.

Owner:邓文

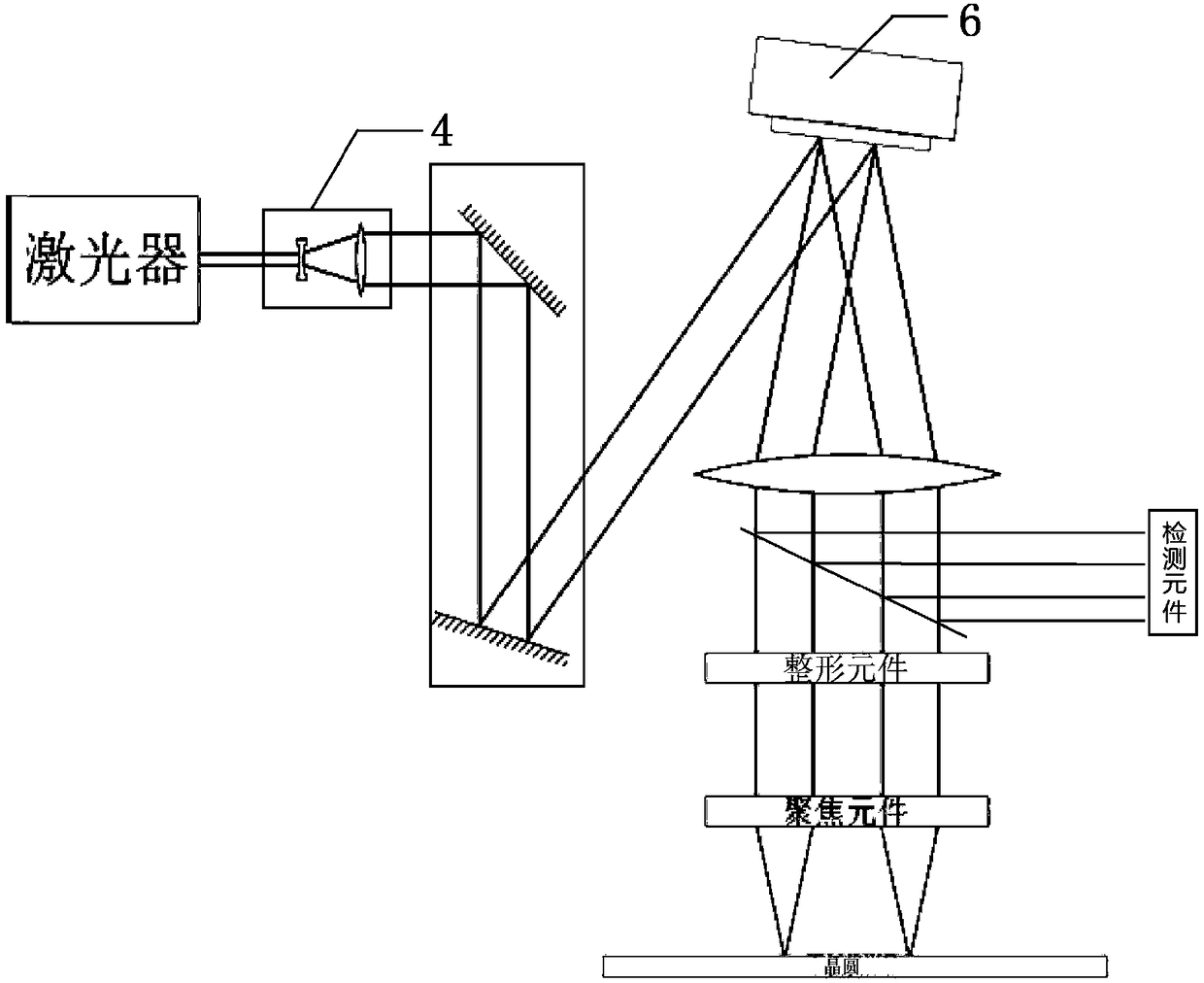

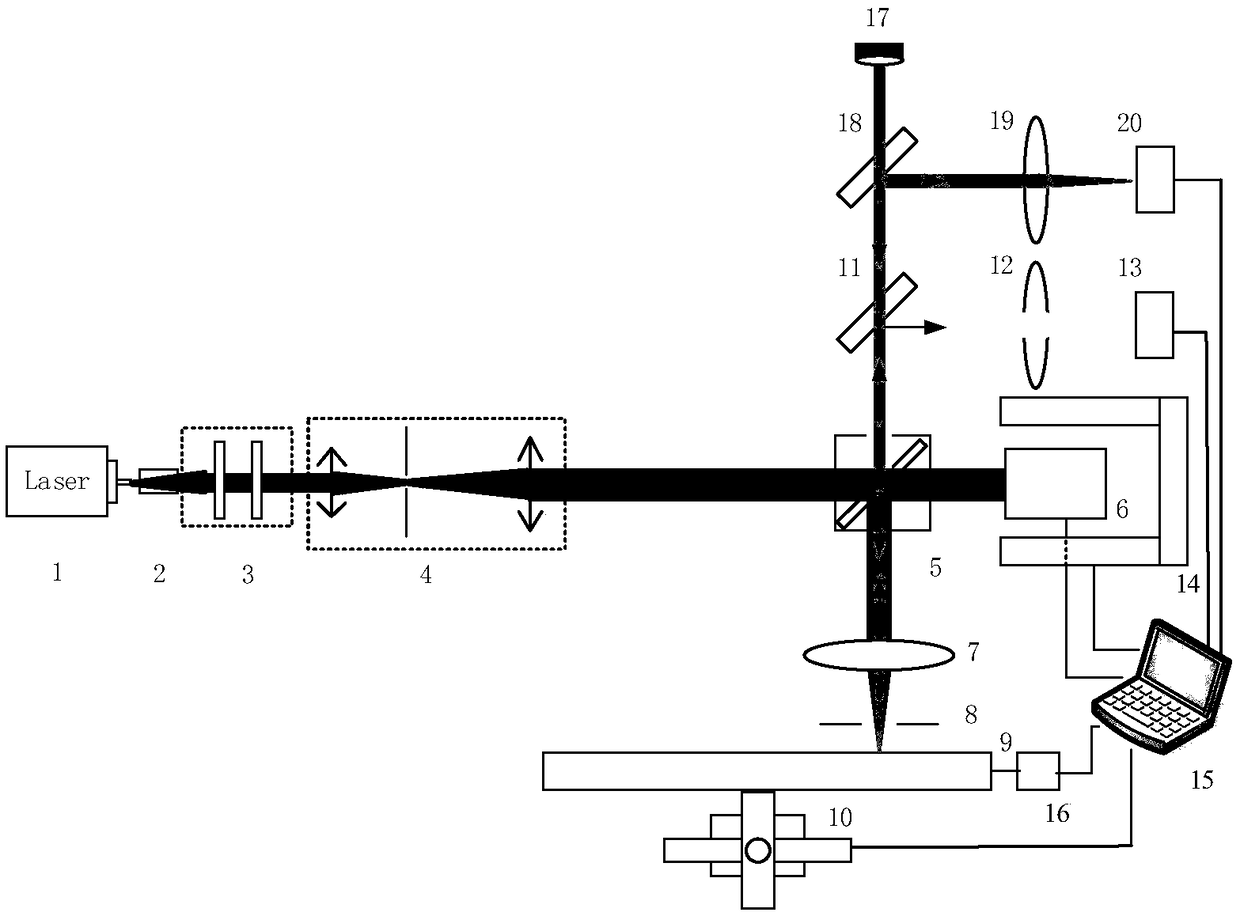

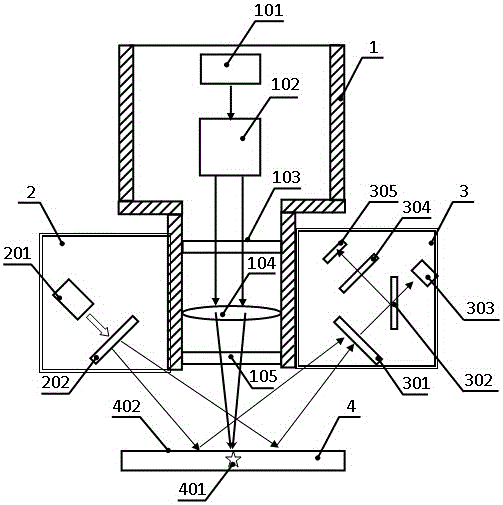

Device and method for laser processing wafer

ActiveCN107433396BEnhanced beam splitting capabilitiesImprove abilitiesMetal working apparatusLaser beam welding apparatusLaser processingLight spot

The invention provides a device and method for wafer laser processing. The device comprises a laser unit, a beam expanding and collimating element, a phase-controlled-type silicon-based liquid crystal and a focusing element; the laser unit is used for emitting laser beams; the beam expanding and collimating element is used for beam expanding and collimating of the laser beams to form the parallel light beams; the phase-controlled-type silicon-based liquid crystal is used for conducing energy distribution modulation on the parallel light beams to form random customized multi-light-beam assemblies or conducting shape-correction treatment to form flattop light spots to be emitted to the focusing element; and the focusing element is used for emitting the random customized multi-light-beam assemblies or the flattop light spots to the upper surface of a wafer and removing Low-K materials of the upper surface of the wafer in the pre-set cutting way direction. According to the device and method for wafer laser processing, through the phase-controlled-type silicon-based liquid crystal, energy distribution modulation or shape-correction treatment is conducted on the parallel light beams to improve the work efficiency and accuracy of the processing method and the uniformity of wafer separation, and the device and method for wafer laser processing can be suitable for the requirements of the various flattop light spots.

Owner:北京中科镭特电子有限公司

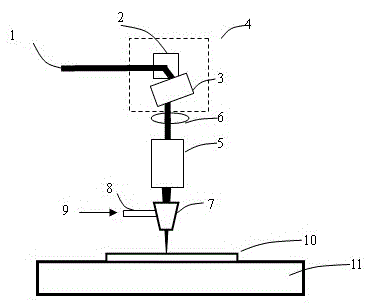

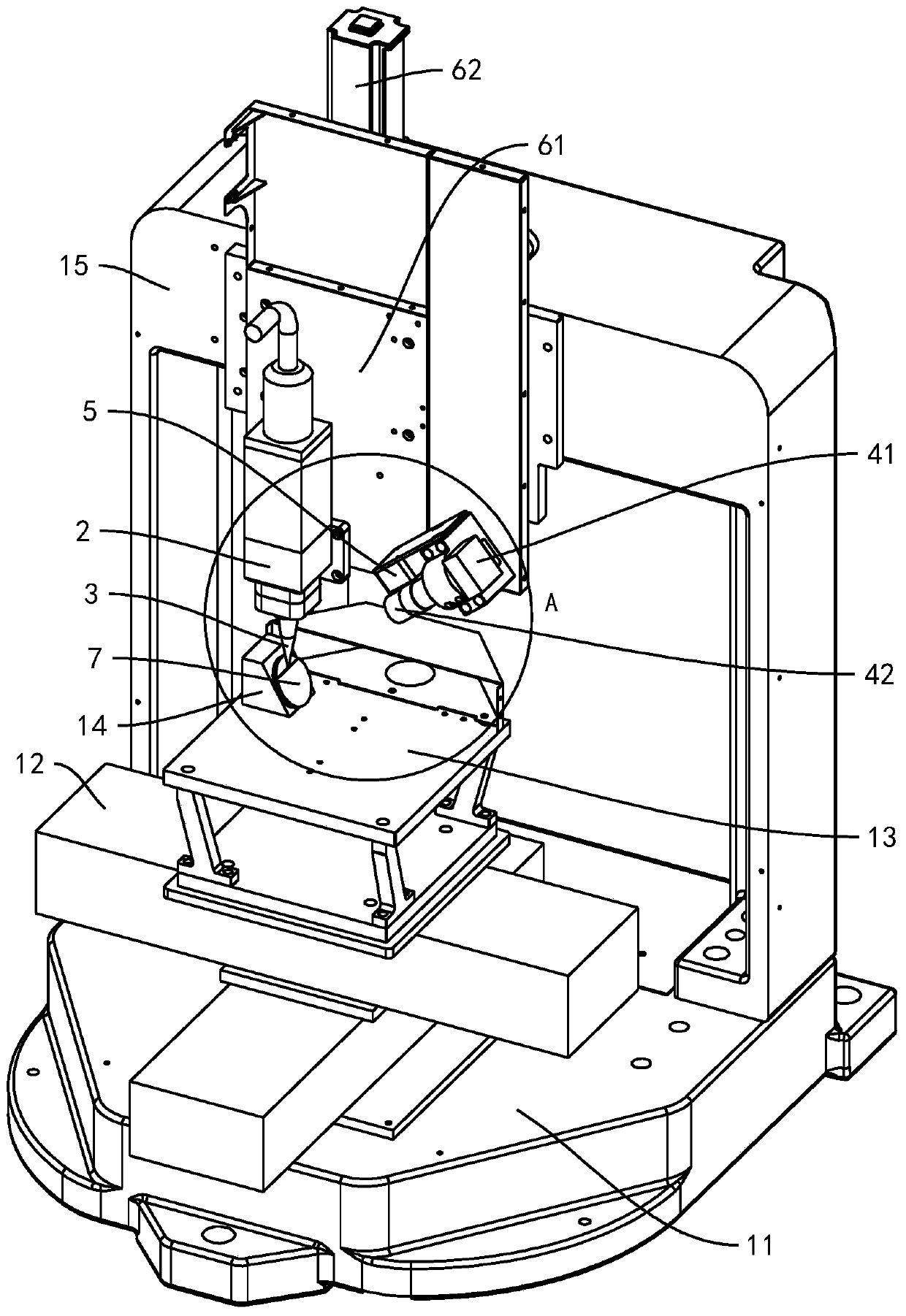

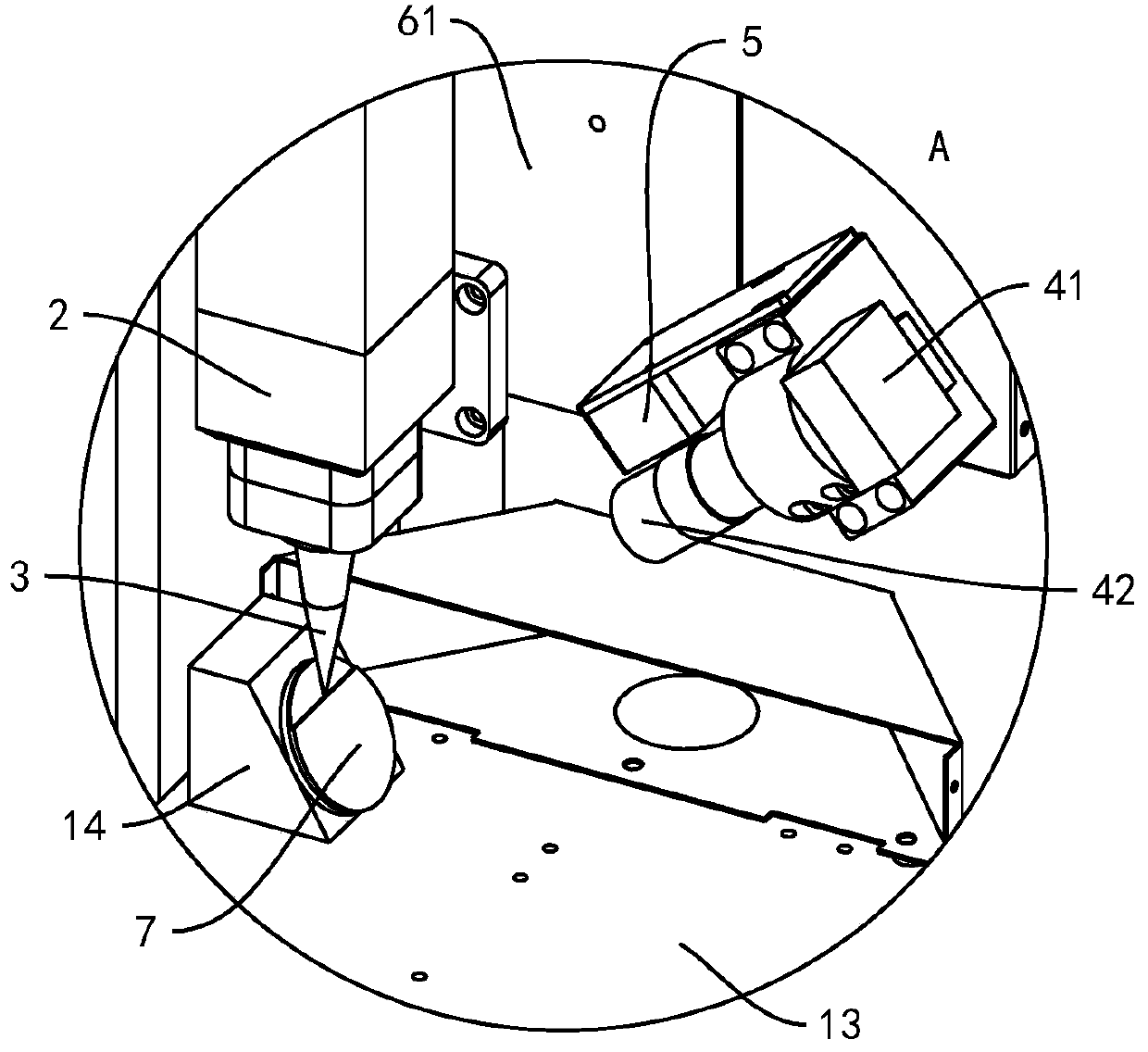

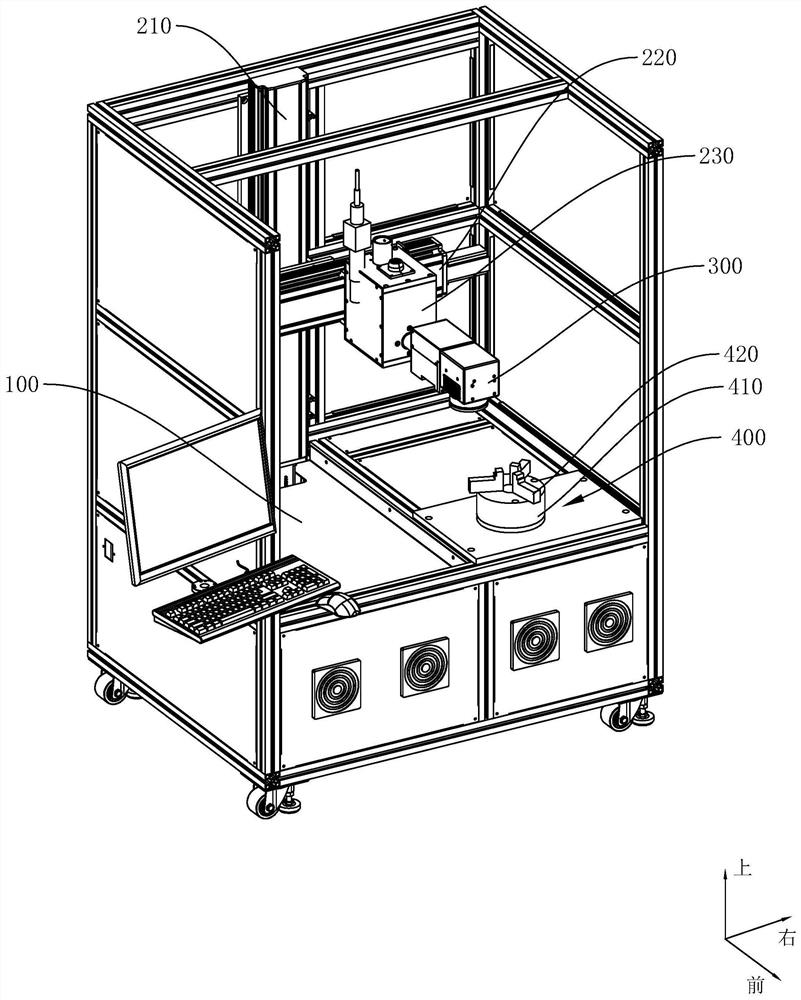

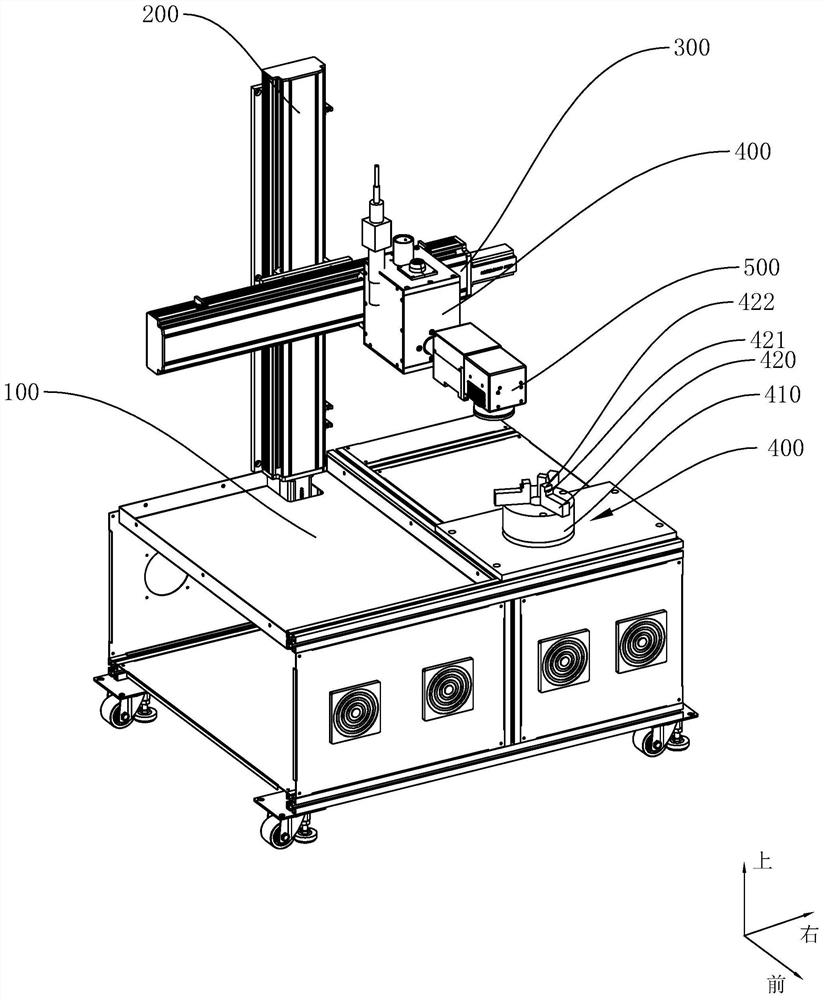

Coaxial curved surface laser processing equipment

InactiveCN111761227AFlexible adjustmentImprove the effect of laser processingWelding/cutting auxillary devicesAuxillary welding devicesLaser processingEngineering

The invention discloses coaxial curved surface laser processing equipment. The coaxial curved surface laser processing equipment includes a machine body. The coaxial curved surface laser processing equipment also includes a laser processing mechanism and a clamping mechanism; the laser processing mechanism includes an adjustment mechanism and a laser, and the adjustment mechanism is connected to the laser in a driving manner, so as to drive the laser to move horizontally in left and right directions, move vertically in up and down directions, and rotate around an axis in the left and right directions; and the clamping mechanism includes a rotation driving device and a clamping assembly, the clamping assembly includes a clamping table, the clamping table has a rotation axis, and the rotation driving device drives the clamping table to rotate around the rotation axis. By using the coaxial curved surface laser processing equipment disclosed by the invention to perform laser processing ona specific position of a revolving curved surface, the laser can be flexibly adjusted to adapt to the processing surface and improve the laser processing effect.

Owner:佛山市富兰激光科技有限公司

Method and device for laser processing wafers

ActiveCN107234343BImprove uniformityImprove the effect of laser processingWelding/soldering/cutting articlesLaser beam welding apparatusHeat-affected zoneLaser processing

Owner:北京中科镭特电子有限公司

Laser two-dimensional code ear tag modification material special for breeding stock and preparation method

The invention discloses a laser two-dimensional code ear tag modification material special for breeding stock. The modification material is characterized by comprising the following materials in part by weight: 97 to 99 parts of polyurethane, 1.5 to 2.5 parts of antimony trioxide, 0.01 to 0.03 part of dispersant and 0.05 to 0.09 part of coupling agent. By using the advantages of the thermoplasticpolyurethane such as oil resistance, toughness, abrasion resistance, ageing resistance and the like and adding a photo-oxidation stabilizing auxiliary agent, the weather resistance of the material isimproved, and the problems of ageing, brittleness, breakage, drop and the like under the actions of air, sunlight and oxygen after an ear tag is worn for long time are solved; and by adding a modifying material into the polyurethane, the laser processing performance of a thermoplastic polyurethane elastomer is enhanced, and batch production of laser processing on the thermoplastic polyurethane elastomer material is realized. Tested by the applicant, the drop, breakage or fracture rate of the ear tag made of the modification material does not exceed 2 percent when the ear tag is worn by the breeding stock in three years.

Owner:贵阳维隆塑胶有限公司

Method and device for laser processing wafer

ActiveCN107214419BAvoid damageHigh control precisionMetal working apparatusLaser beam welding apparatusLaser processingHigh energy

The invention provides a laser machining method and device for a wafer. The method comprises that at least two laser beams having different energy distribution respectively execute a hacking process and a grooving process on a predetermined cutting path on the upper surface of the wafer in sequence and are used for forming a groove in the predetermined cutting path on the upper surface of the wafer. The predetermined cutting path on the upper surface of the wafer can be hacked by the laser beams with lower energy, the surface of the predetermined cutting path is roughened to improve a light absorptivity, which is convenient for preparation for a subsequent machining process, and the wafer is prevented from being damaged by stripping of a Low-K material caused by a fact that a Low-K layer on the surface of the wafer is machined by adopting the laser beams with over high energy; and meanwhile, the control precision on the energy of the laser beams in a subsequent machining process is higher, and further a laser machining effect of the upper surface of the wafer is improved.

Owner:北京中科镭特电子有限公司

Method and device for laser processing wafer

ActiveCN107685196BTo meet the needs of subsequent processingThe groove wall is steepLaser beam welding apparatusLaser processingOptoelectronics

The invention provides a wafer laser-machining method and device. The relative positions of a laser beam and a predetermined cutting path are changed in the direction of the predetermined cutting pathon the upper surface of a wafer, so that a groove is formed in the predetermined cutting path. The method comprises the steps that a flattop light spot is formed on the predetermined cutting path after the laser beam is subjected to shape correction treatment; the flattop light spot is subjected to defocusing treatment, and M-shaped energy distribution with the edge energy greater than the intermediate energy is formed; the flattop light spot with the M-shaped energy distribution is used for etching the predetermined cutting path, so that the groove is formed; and the flattop light spot is subjected to defocusing treatment, energy flattop distribution is formed, and then the flattop light spot with the energy flattop distribution is used for etching the groove again. According to the wafer laser-machining method and device, the wafer can be etched through the flattop light spot with the different energy distribution forms in sequence, the groove bottom of the groove is flatter, the groove wall is steeper, the groove shape quality of the groove is improved, and subsequent machining requirements and the laser machining yield are guaranteed.

Owner:北京中科镭特电子有限公司

Heat Curable Conductive Paste

ActiveCN106941018BEasy to thermally decomposeGood removal effectNon-conductive material with dispersed conductive materialConductive pastePolymer science

To provide a thermosetting electrically conductive paste excellent in laser processability and enabling an electrode having high electrical conductivity to be formed. According to the present invention, the thermosetting electrically conductive paste is provided. The thermosetting electrically conductive paste contains an electrically conductive powder, a thermosetting resin and a curing agent. The electrically conductive powder contains a non-agglomerated electrically conductive powder and an agglomerated electrically conductive powder different from each other in a degree of agglomeration expressed by a ratio (L-D 50 / SEM-D 50) between a number-basis average particle size (SEM-D 50) based on electron microscope observation and a volume-basis average particle size (L-D 50) based on a laser diffraction scattering particle size distribution measurement method. The degree of agglomeration of the non-agglomerated powder is 1.5 or smaller, the degree of agglomeration of the agglomerated powder exceeds 1.5 and is 3 or smaller, the L-D 50 of the agglomerated electrically conductive powder does not exceed L-D 50 of the non-agglomerated electrically conductive powder.

Owner:NORITAKE CO LTD

Photosensitive epoxy resin composition for formation of optical waveguide, curable film for formation of optical waveguide, optical waveguide produced by using the resin composition or the curable film, and hybrid flexible printed wiring board for optical/electrical transmission

ActiveUS20200071454A1Improve adaptabilityReduce viscosityCircuit optical detailsPhotomechanical apparatusEpoxyPolymer science

A photosensitive epoxy resin composition for formation of an optical waveguide is provided, which contains an epoxy resin component, and a photo-cationic polymerization initiator, wherein the epoxy resin component includes a solid semi-aliphatic bifunctional epoxy resin. The optical waveguide formation photosensitive epoxy resin composition is usable as an optical waveguide forming material having higher R-to-R (roll-to-roll) adaptability (lower tackiness and uncured-state flexibility), a lower refractive index, excellent patternability, and excellent laser processability mirror forming processability).

Owner:NITTO DENKO CORP

Resin composition for laser processing

ActiveCN104169370APromote absorptionImprove the effect of laser processingCoatingsCircuit masks compositionResistLaser processing

Provided is a resin composition for laser processing, in which laser workability can be improved while post-ultraviolet laser processing resist properties of resin are maintained, and which can be used as a resist that is employed when forming circuits in printed circuit boards, for example. The resin composition for laser processing contains resin and an ultraviolet light absorbing agent, wherein the resin has a carboxyl group and is a thermoplastic resin with a softening point of 70-140°C, and the ultraviolet light absorbing agent content of the resin is 1-30 parts per 100 parts of thermoplastic resin.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Controllable Laser Processing Device Based on Wavefront Modulation

InactiveCN105537760BUnleash the full potential of processing characteristicsAchieve shapingLaser beam welding apparatusWavefrontLaser processing

The invention relates to a controllable laser processing device based on wavefront modulation. The controllable laser processing device based on wavefront modulation comprises a laser processing head, an irradiation module and a photoelectric detection analysis module. The irradiation module and the photoelectric detection analysis module are located in different positions of the laser emitting mechanical edge of the laser processing head. Emitting beams of the irradiation module cover the laser processing working area and peripheral areas of the laser processing head, and light fields inside the emitting beam coverage area of the irradiation module are incident on the photoelectric detection analysis module. A light filed wavefront modulation element is arranged on a laser processing light path, so that shaping is achieved by focusing light spots, the laser processing performance is improved, and an optical material analysis technology and a photoelectric position detection technology are combined. Emitting light of the irradiation module irradiates the laser processing area and the peripheral areas of the laser processing head, material composition information and movement position information inside the irradiated areas are detected by the photoelectric detection analysis module, the phenomenon that a non-processing object enters the laser processing area is avoided, and laser of the laser processing device is safe and controllable.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

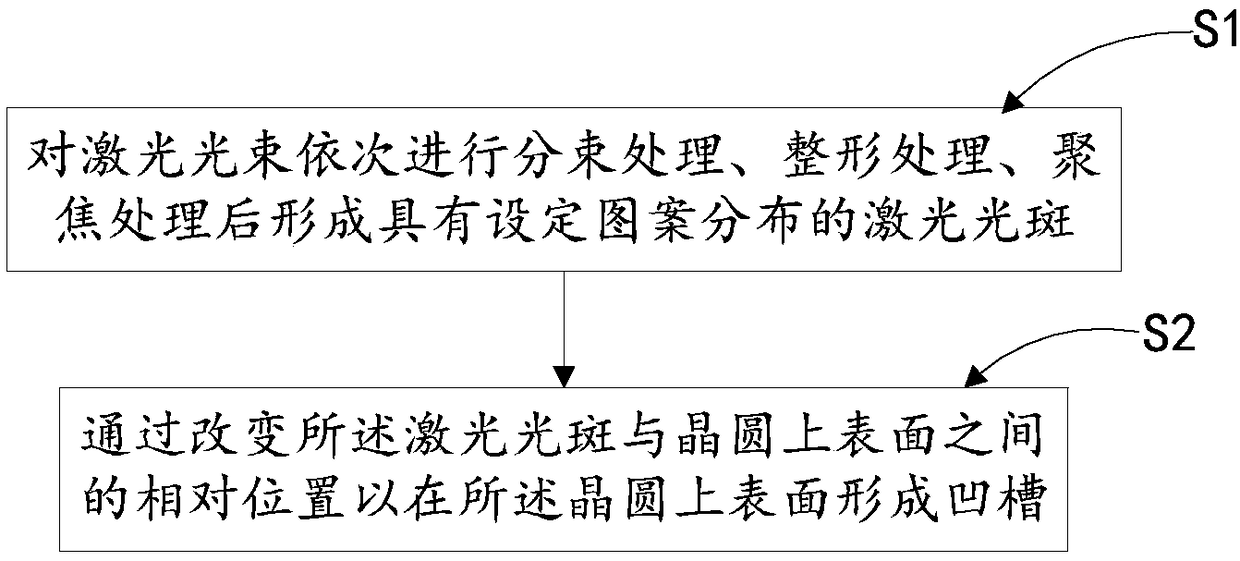

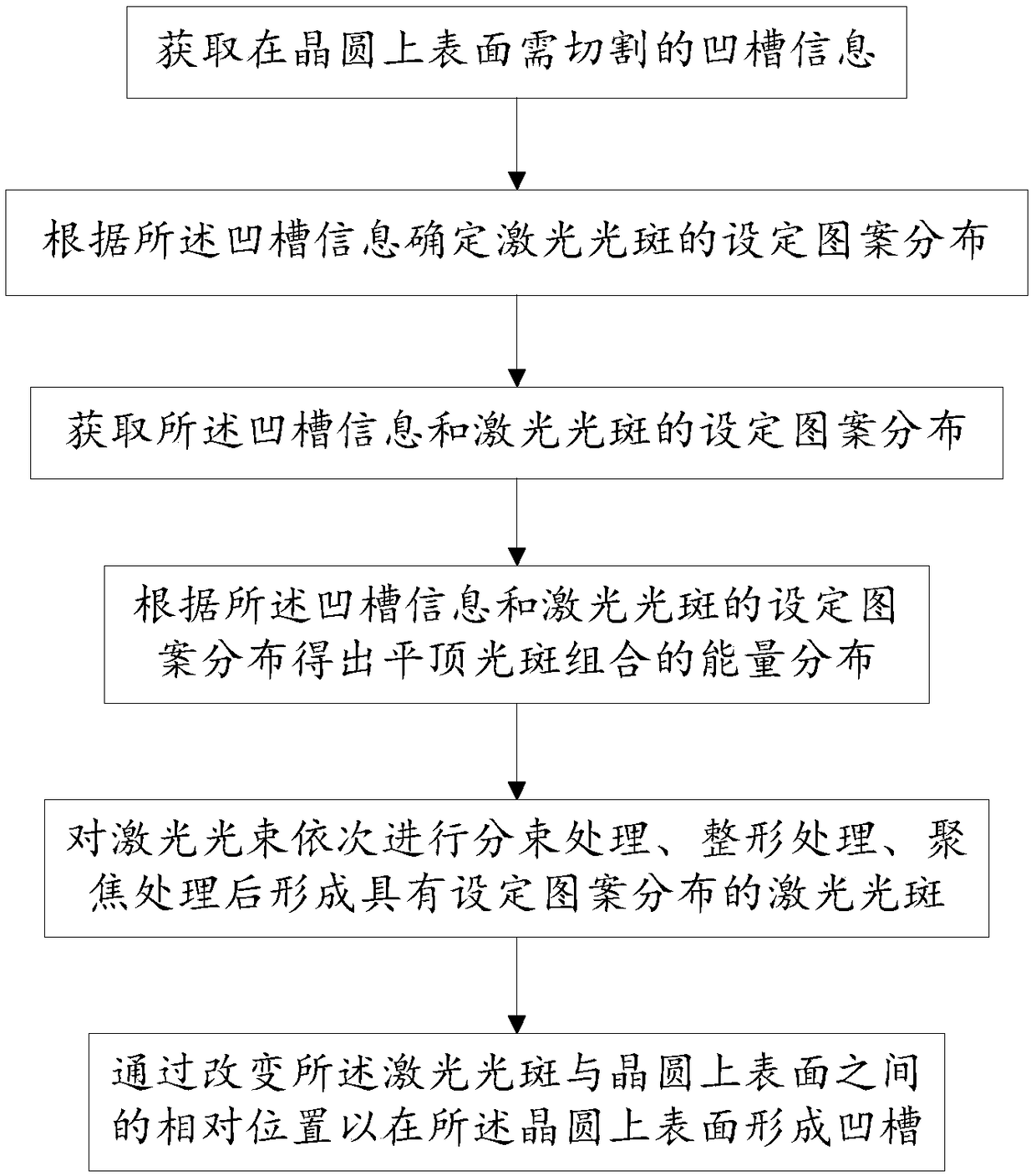

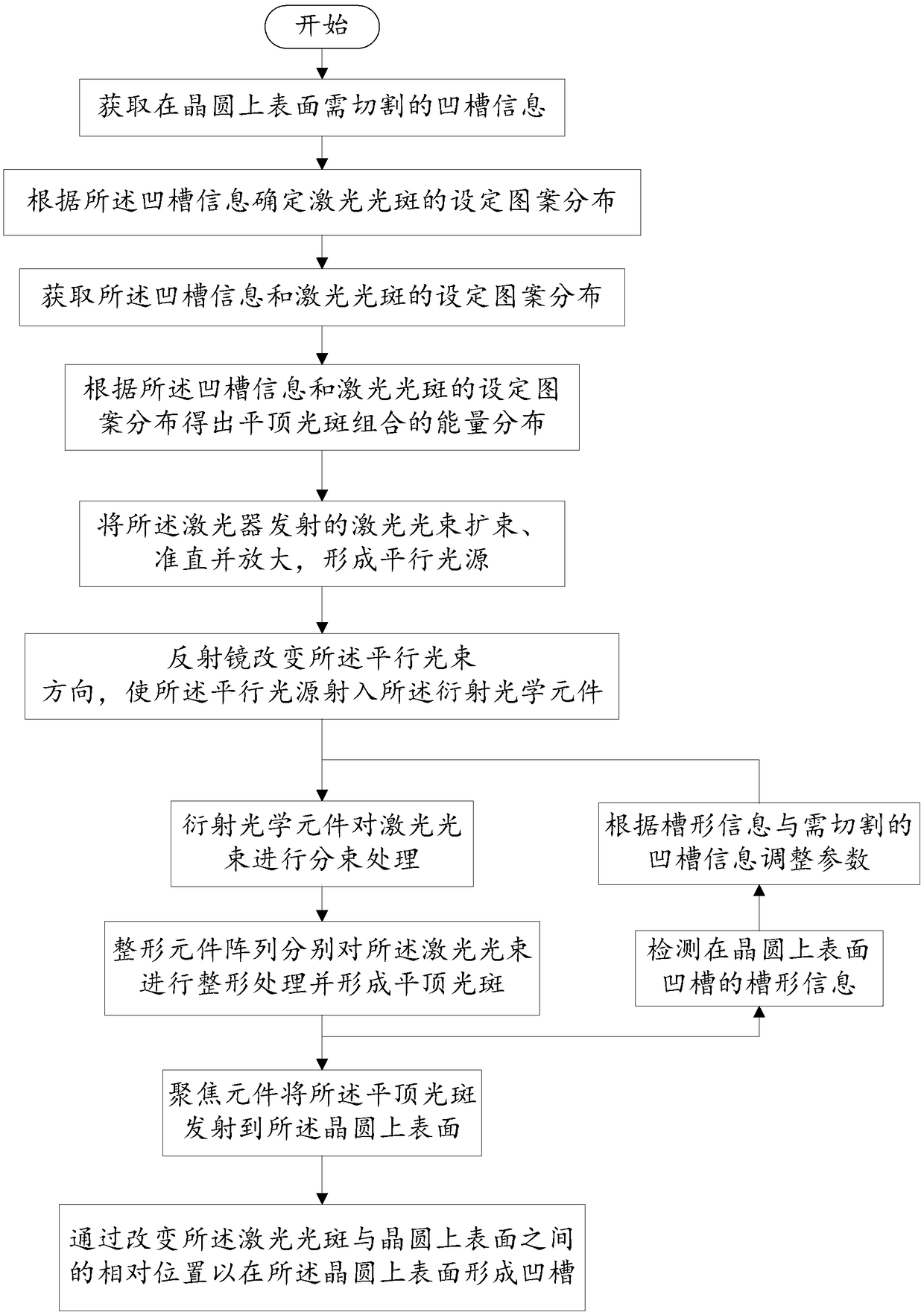

Method and device for laser processing wafer

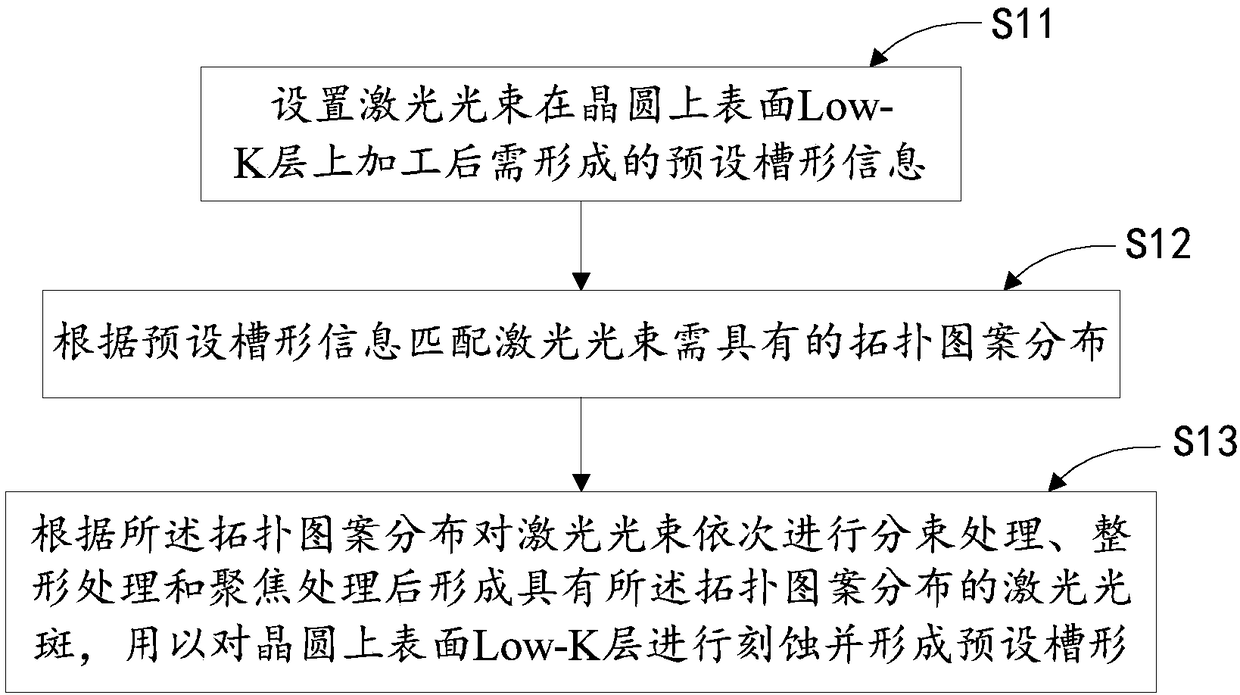

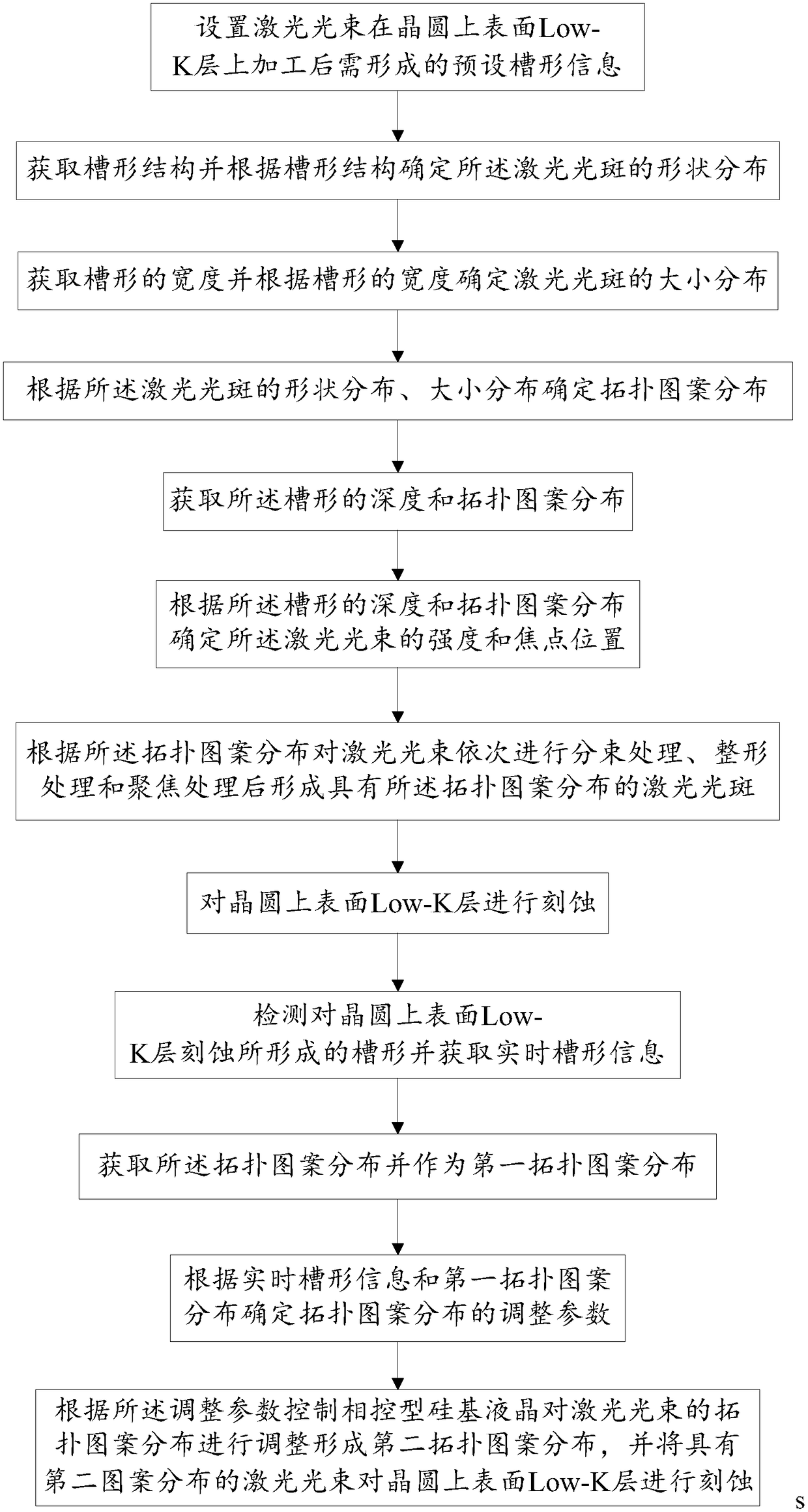

ActiveCN107214420BImprove the effect of laser processingImprove uniformityMetal working apparatusLaser beam welding apparatusLaser processingHeat-affected zone

The invention provides a method and device for machining wafers through laser. The method comprises the steps that after beam splitting treatment, shaping treatment and focusing treatment are sequentially carried out on laser beams, laser spots with set pattern distribution are formed; and space positions of the laser spots are adjusted so that grooves can be formed in the upper surfaces of the wafers. According to the method and the device, in the wafer laser machining process, according to the characteristic of the grooves, the laser beams are matched to the optimal set pattern distribution, energy of the scribed laser beams can be distributed more uniformly, the grooves formed in the upper surfaces of the wafers are more uniform, the heat influence area is smaller, uniformity is higher, and then the laser machining effect on the upper surfaces of the wafers is improved.

Owner:北京中科镭特电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com